Integrated flue gas condensing waste heat recovery boiler

A waste heat recovery boiler and flue gas condensation technology, applied in steam boilers, air heaters, fluid heaters, etc., can solve problems such as poor corrosion resistance, corrosion, and short service life, and achieve strong corrosion resistance and compact overall structure , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

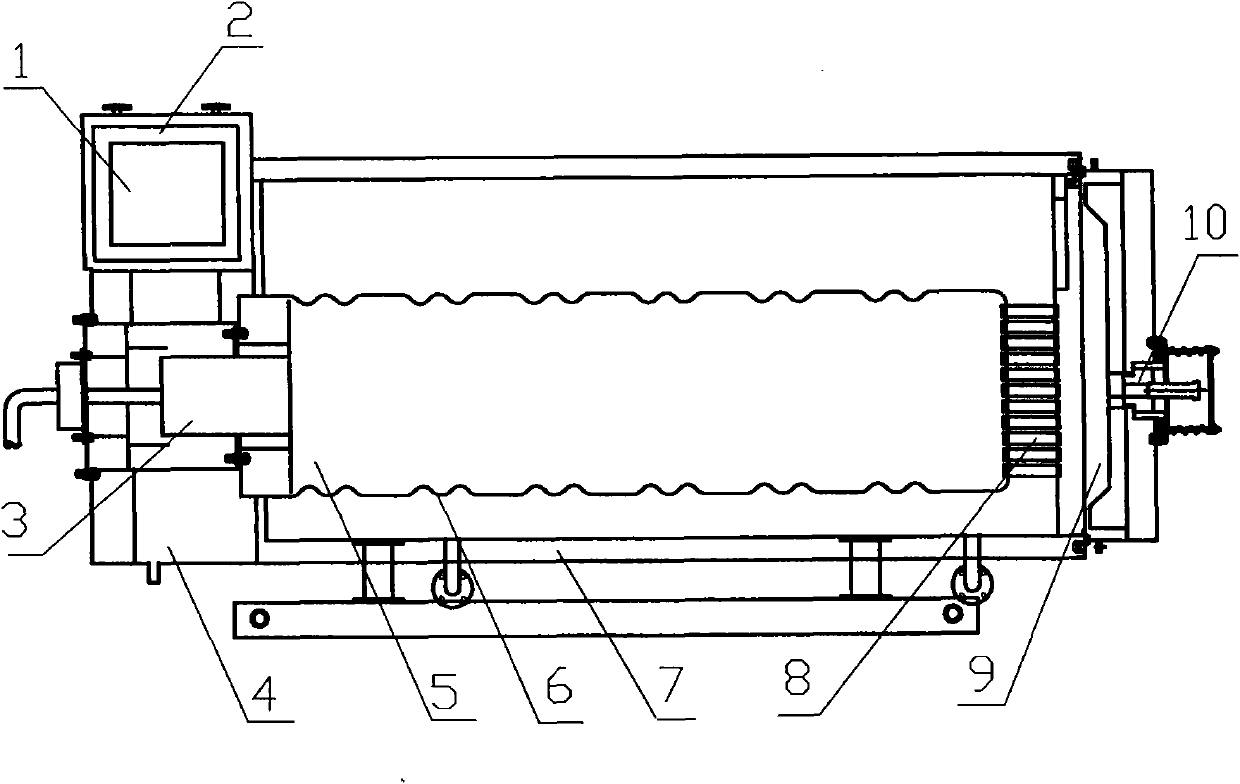

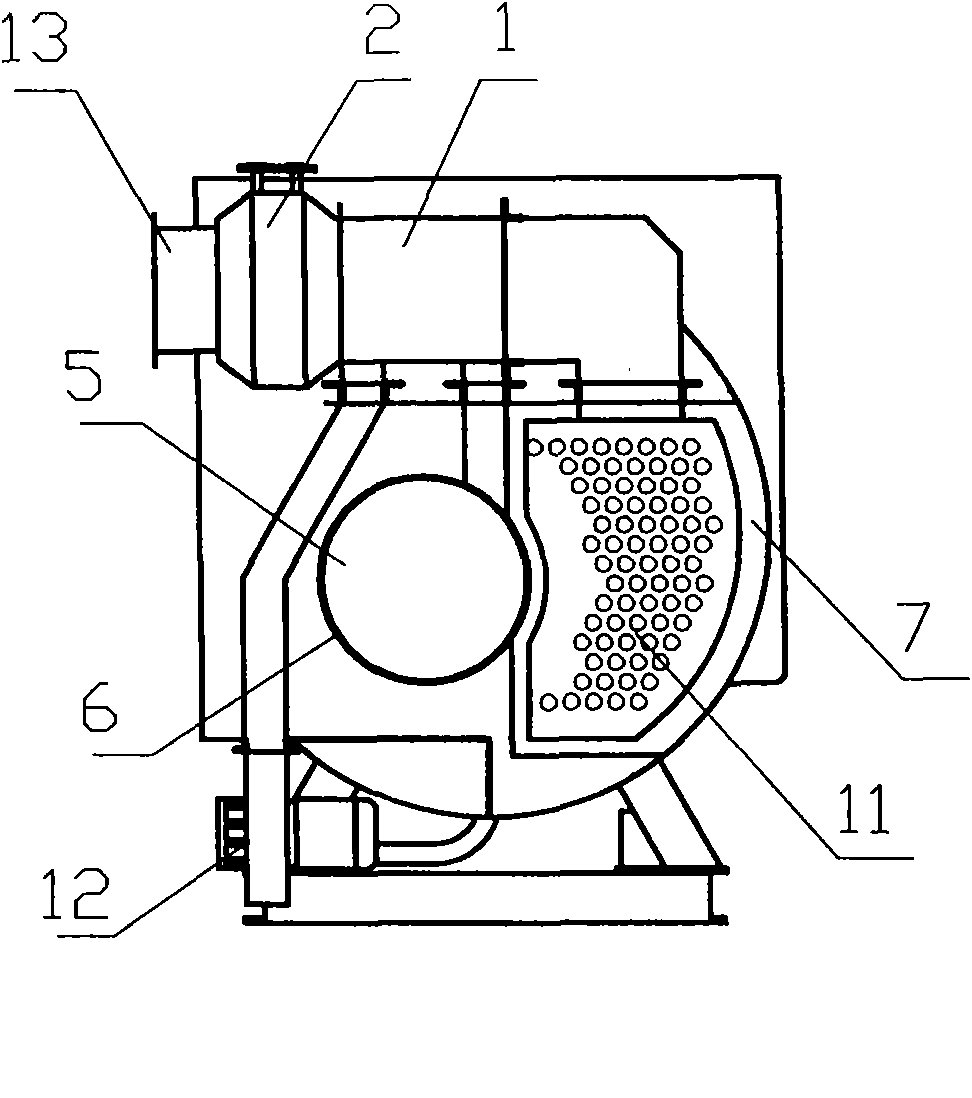

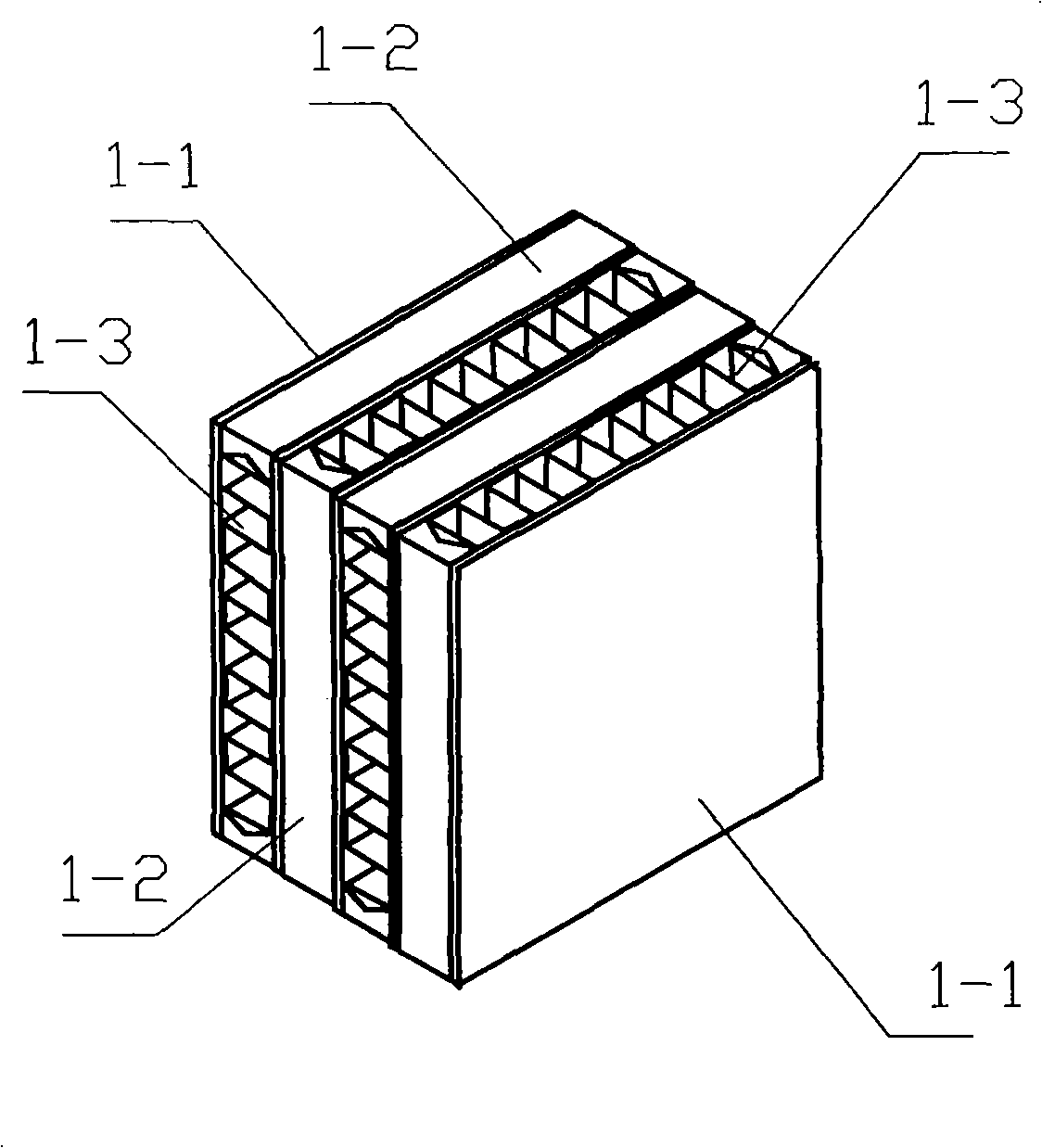

[0014] The air inlet of the plate-fin air preheater 1 is connected to the blower 12 , and the air outlet is connected to the air inlet of the burner 3 . The air preheater 1 is composed of partitions 1-1, fins 1-3 and heads 1-2 to form a plane, 20 to 50 planes are stacked and combined, and the adjacent planes are rotated by 90 degrees, when one side of the fin inlet When it is an air channel, the fin inlet on the other side at 90 degrees is a flue gas channel. The material of the partition is to cover a layer of brazing alloy with a thickness of about 0.1-0.4mm and a silicon content of 5-12% on the surface of the parent metal (aluminum-manganese metal). The thickness of the partition is 0.36-2mm, and the thickness of the cover plate is 5-6mm. The flame port of the burner 3 is connected to the left end of the furnace 5, the shell of the furnace 5 is a corrugated furnace 6, and the right end of the corrugated furnace 6 is a furnace roof, and the furnace roof and the front wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com