Sectional boiler

a sectional boiler and boiler body technology, applied in the direction of indirect heat exchangers, conduit assemblies of stationary plates, lighting and heating apparatus, etc., can solve the problems of less favorable scaling conditions especially in welded constructions, large sizes, and high material costs, and achieve the best suitability for condensing heating operation, good heat transfer properties, and good material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

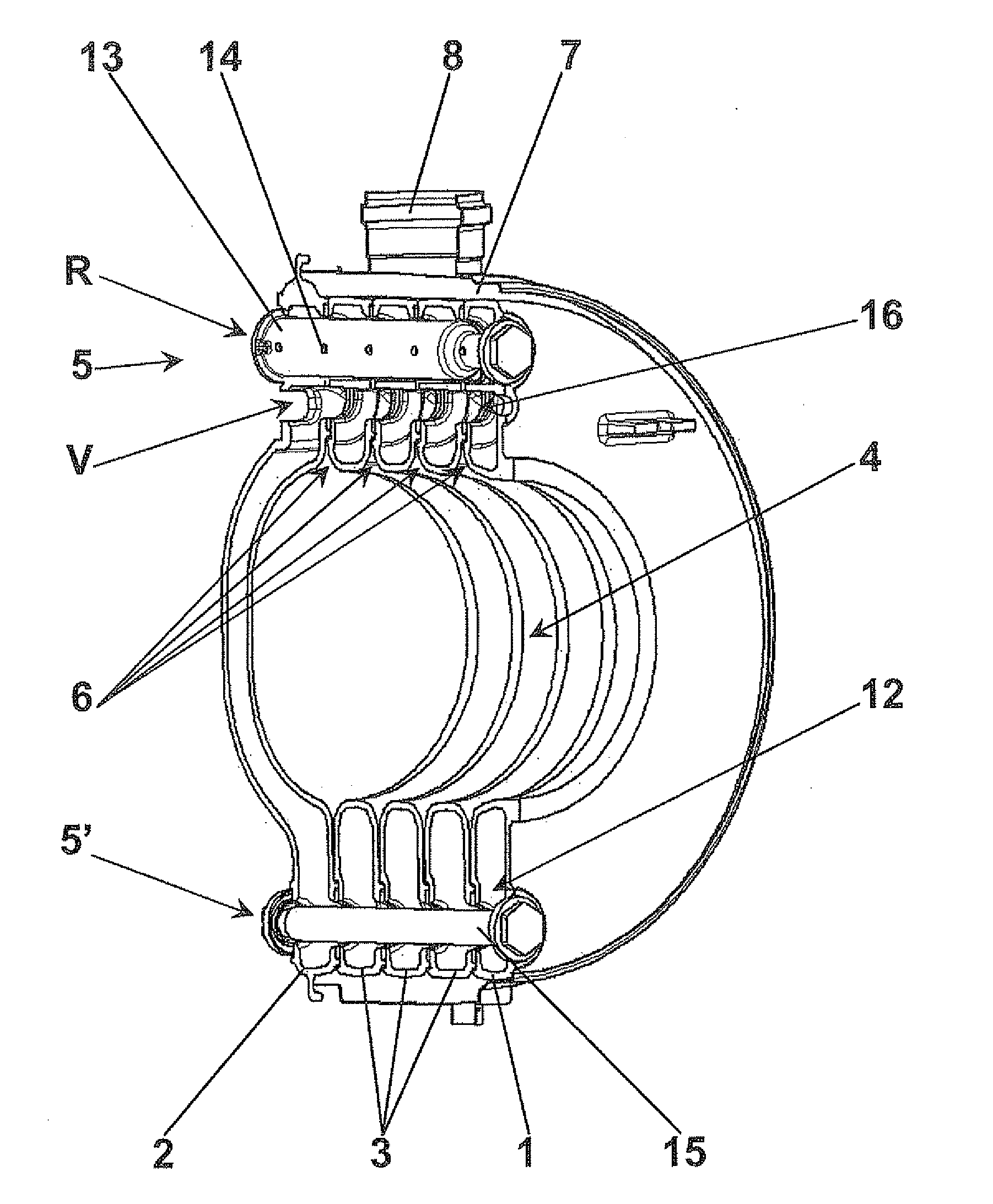

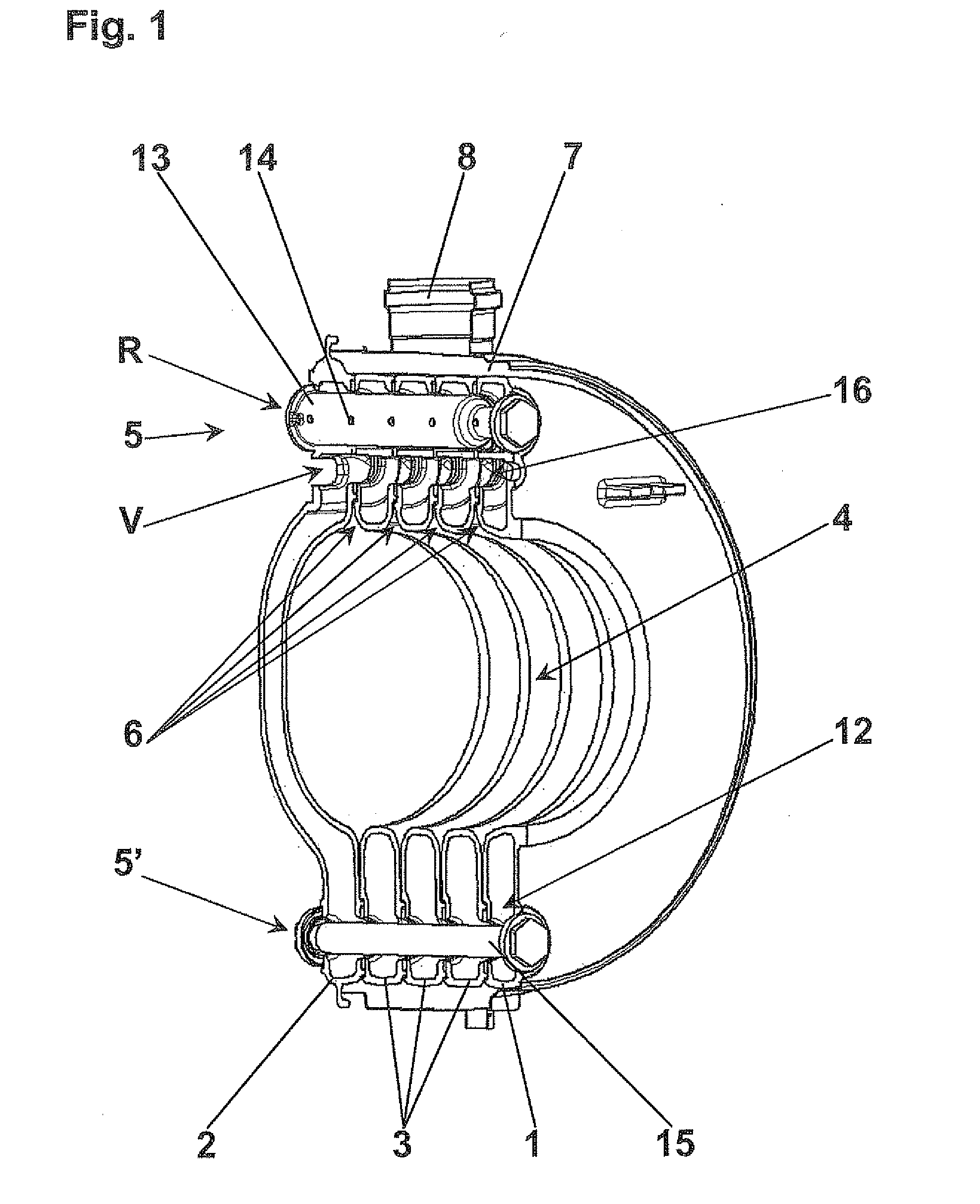

[0026]The sectional boiler is essentially made up of annular sections, namely, a front section 1, a cover-shaped rear section 2 and multiple center sections 3. These form a combustion chamber 4 and respectively have annular water chambers. They are connected to one another via an upper and lower hub 5, 5′.

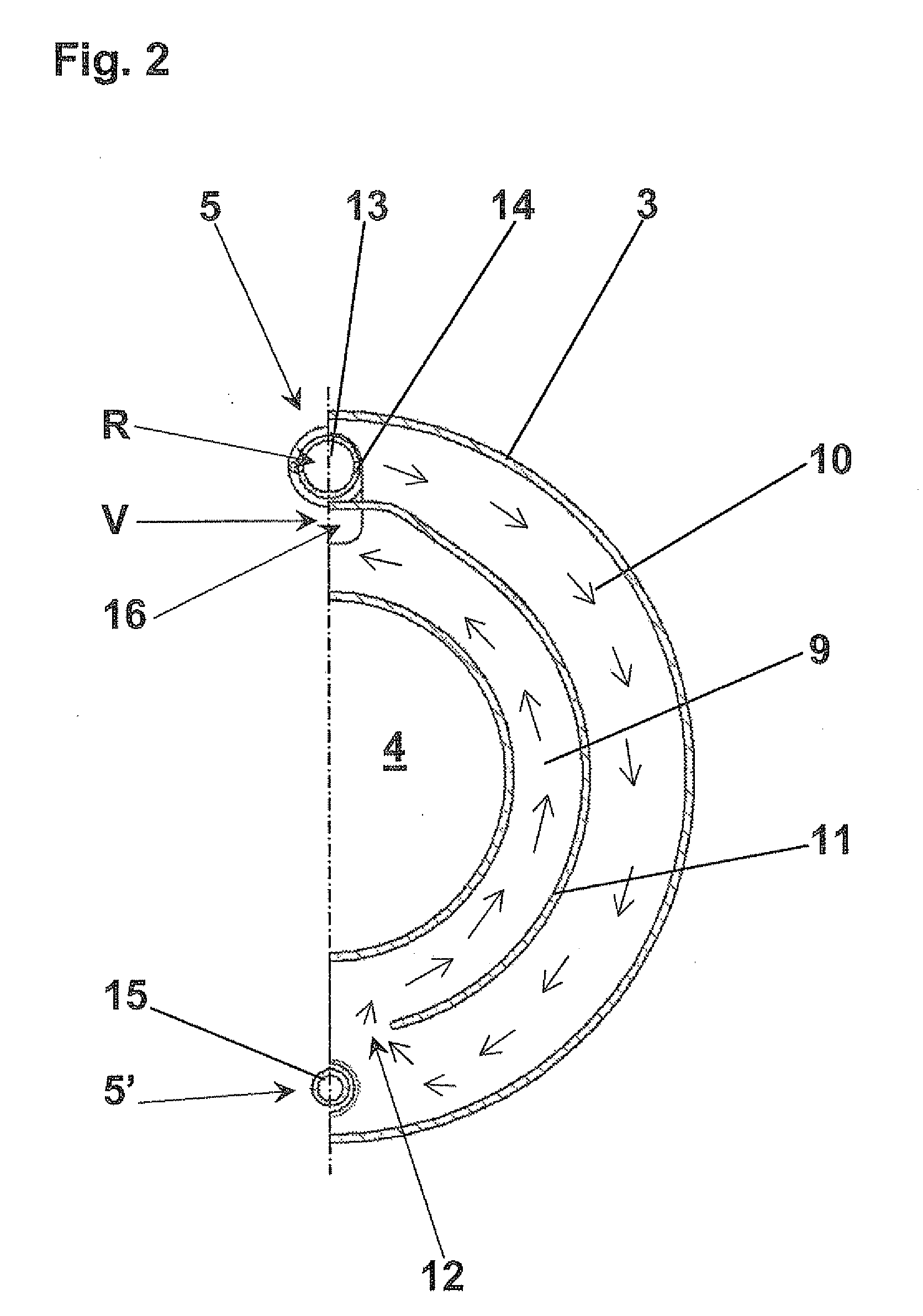

[0027]As heating gas flues, the heat exchanger formed by the sectional block has respectively annular gaps 6 between two adjacent sections 1, 2, 3 having a mutually adapted geometry, which, starting from combustion chamber 4, respectively run approximately radially outward and open into an exhaust gas collection chamber 7 having an exhaust gas connection 8 on the outside of the sections 1, 2, 3.

[0028]On the heating water side, the individual sections 1, 2, 3 are respectively divided into two flow channels 9, 10 and have respectively one separating wall 11 for this purpose. This produces an inner flow channel 9 near the combustion chamber and an outer flow channel 10 of a greater di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com