A narrow-gap oblate double-coil integral condensing boiler

A technology of condensing boilers and double coils, which is applied to fluid heaters, air heaters, lighting and heating equipment, etc., can solve the problems of complex structure and difficulty in maintenance and repair, so as to increase the convective heat exchange area and strengthen convection. The effect of heat exchange and high heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

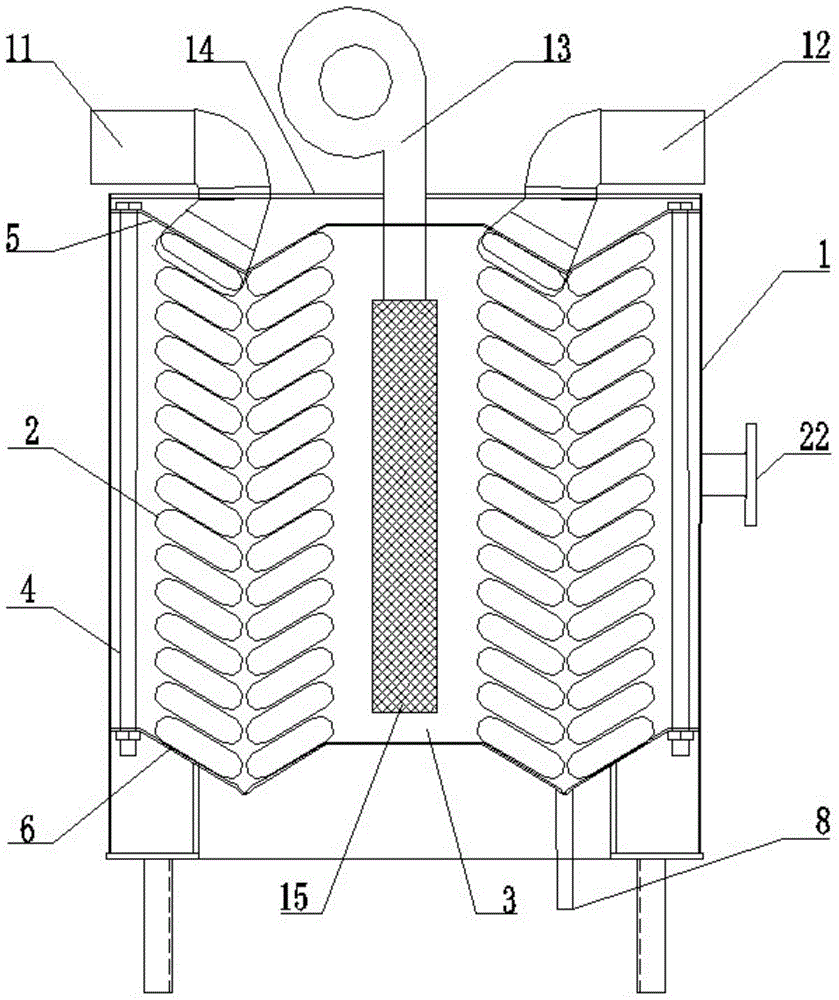

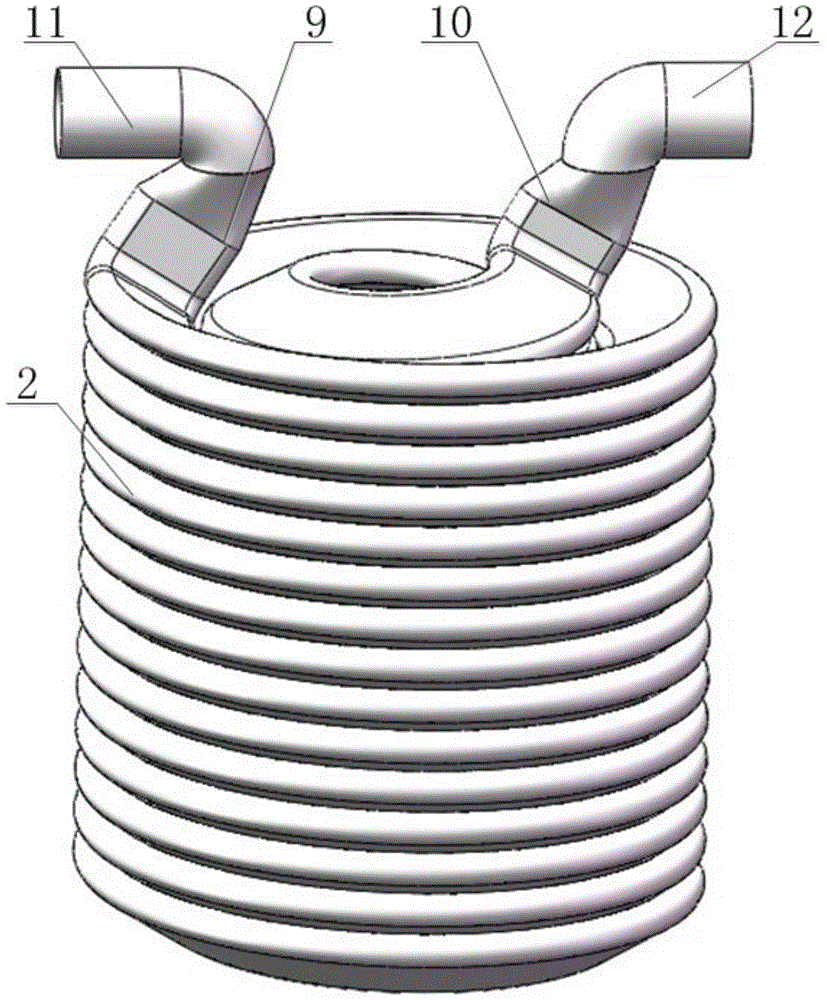

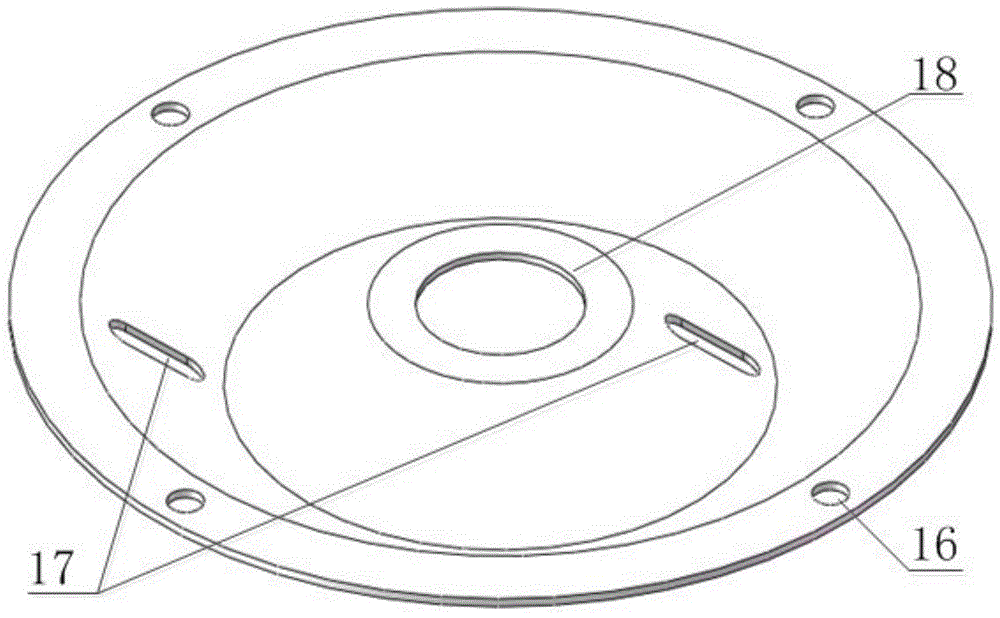

[0028] like figure 1 and figure 2 As shown, the present invention is a narrow-gap oblate double-coil integrated condensing boiler, which includes an outer shell 1, and the heat exchanger in the outer shell 1 is tilted by multiple turns at a preset angle of 5° to 60°, and there are gaps between the turns. The circular double-coil tube 2 is composed of the oblate double-coil tube 2, which is made of a flat circular tube from the top to the bottom of the outer tube ring and then from the bottom to the top of the inner tube ring, and the inner tube ring is surrounded by the structure The radiant heat exchange space 3 in the condensing boiler furnace, the oblate double-coil tube 2 is fastened between the disc-shaped upper partition 5 and the disc-shaped lower partition 6 by four bolts 4, the oblate double-coil tube 2 The topmost opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com