Gas condensation boiler with narrow gap combustion and heat exchange function

A technology of condensing boilers and narrow gaps, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of commercial gas-fired stainless steel coil condensing water heaters with large volume, expensive molds, complicated coil processes, etc., and achieve safety Stable and efficient combustion, easy maintenance and compact combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

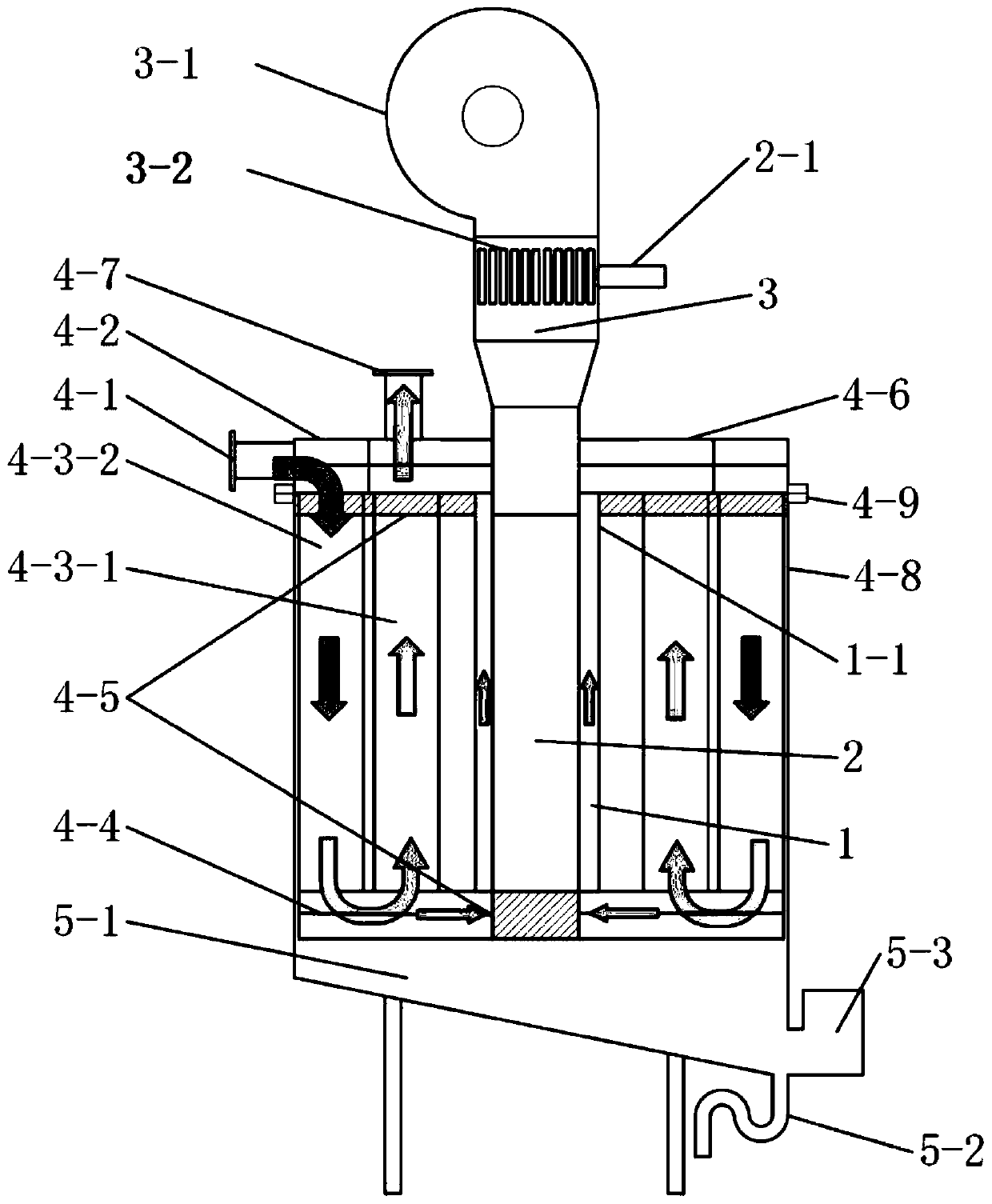

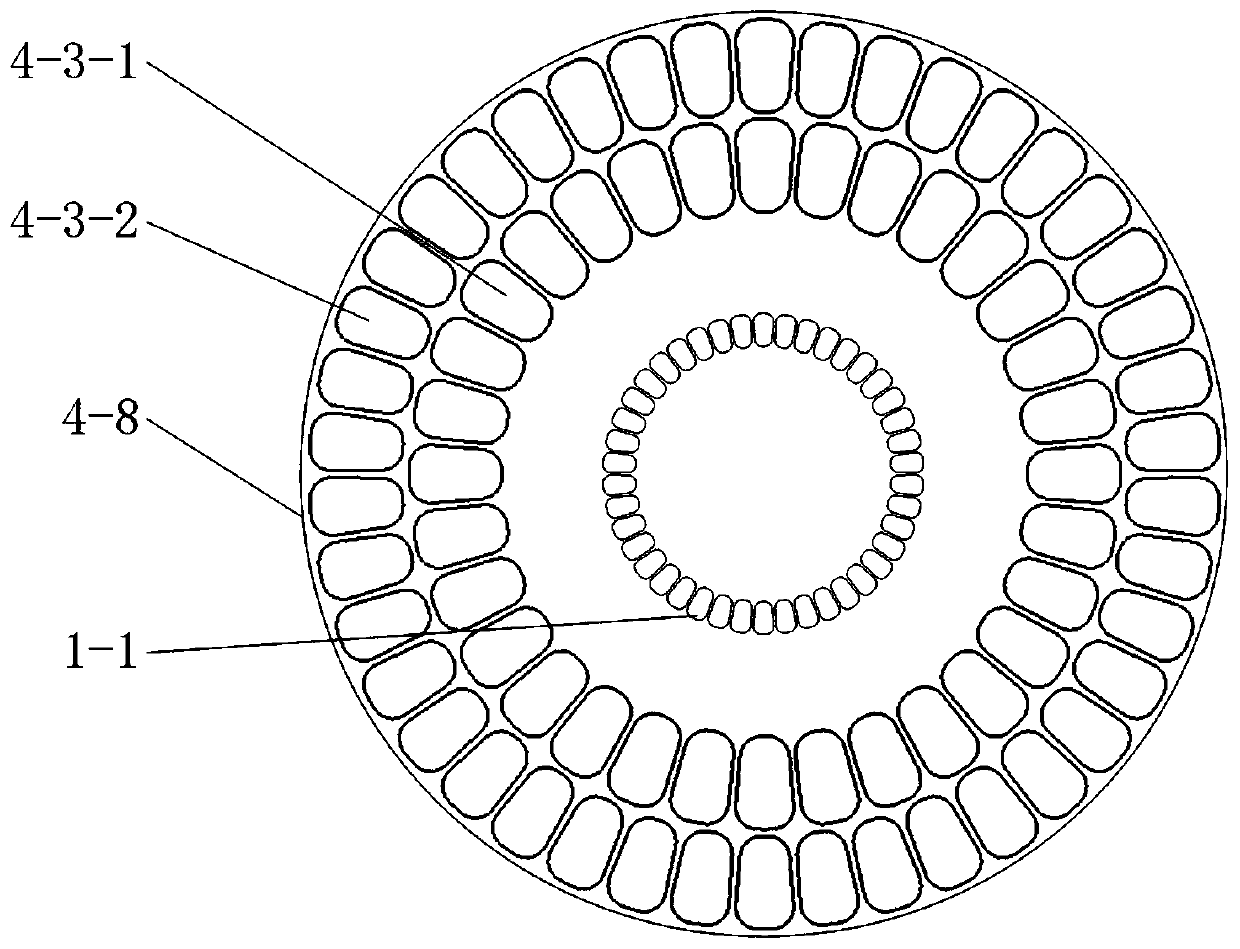

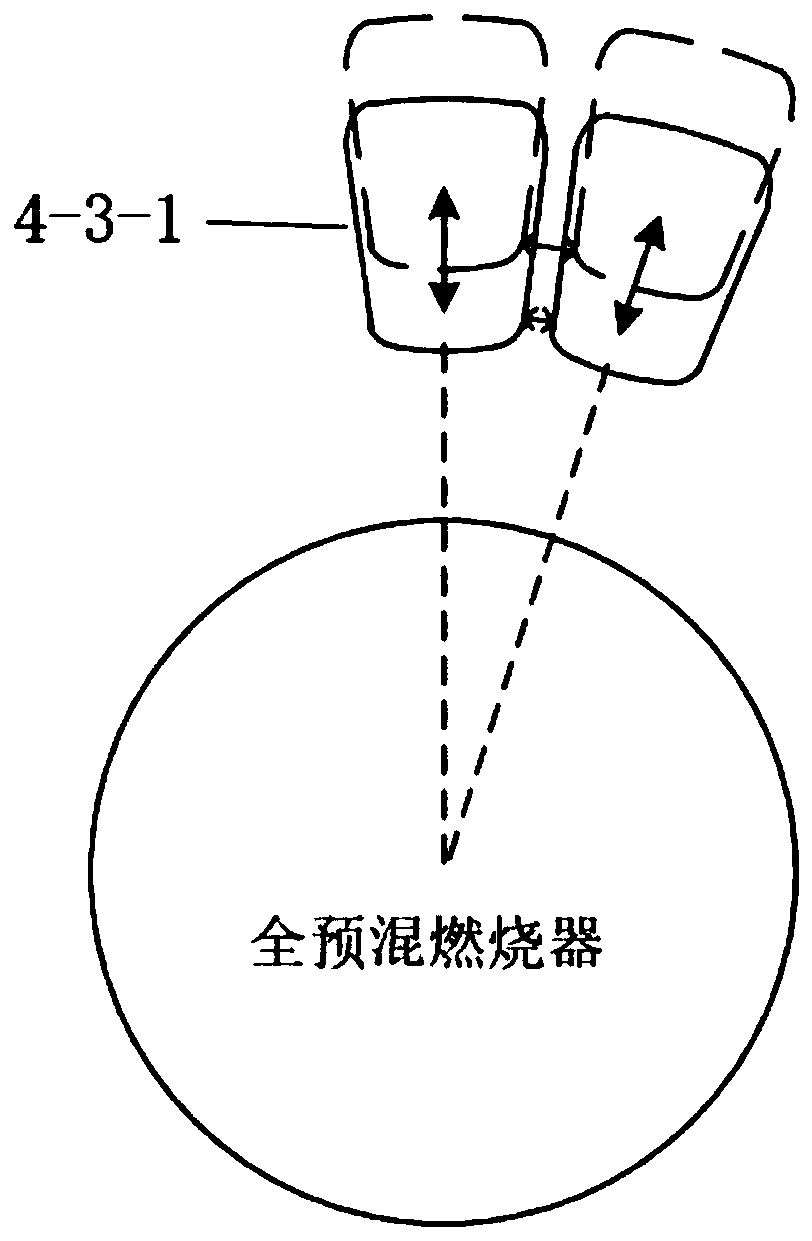

[0042] Such as figure 1 and figure 2 As shown, a gas-fired condensing boiler with narrow gap combustion and heat exchange in the present invention includes a shell 4-8, and the narrow gap heat exchanger in the shell 4-8 is composed of one or more rounds of cylindrically arranged corn grain-shaped straight tubes , the inner layer of corn grain-shaped straight tube 4-3-1 surrounds the radiation heat exchange space in the condensing boiler furnace, and the center of the radiation heat exchange space is the head 1 of the full premix burner; the full premix burner is installed on the shell 4- 8, the fully premixed burner head 1 goes deep into the radiation heat exchange space in the furnace for combustion and heat release, and the flue gas flows from the inner corn kernel-shaped straight pipe 4-3-1 and the outer corn kernel-shaped straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com