Low energy consumption system for purifying and incinerating harmful gases

A waste gas purification and low energy consumption technology, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of dusty and harmful waste gas blockage, incomplete combustion of harmful waste gas, and high energy consumption, so as to reduce energy consumption and reduce incineration Effect of Processing Fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

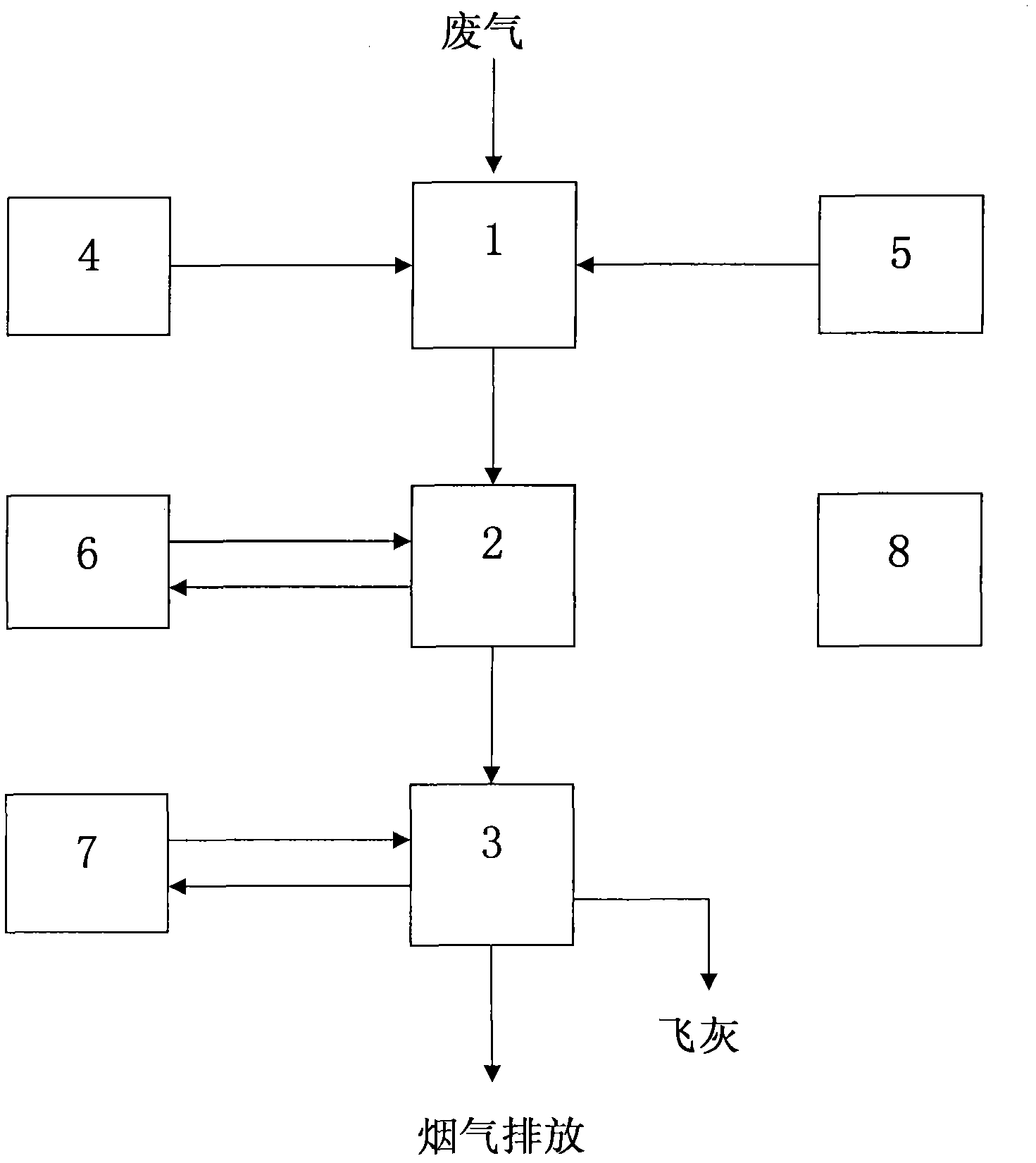

[0018] see figure 1 , low energy consumption harmful waste gas purification and incineration system, including: waste gas purification and incineration unit 1, waste heat recovery unit 2 and flue gas treatment unit 3 and other main equipment, as well as fuel supply equipment 4, combustion air supply equipment 5, heat exchange medium supply equipment 6, Harmful gas adsorbent supply equipment 7, automatic control and safety protection equipment 8 and other auxiliary equipment.

[0019] The exhaust gas purification and incineration unit 1 is composed of a purification incineration chamber shell, refractory and heat preservation materials, a heat storage body, a burner, an exhaust gas spray gun, an explosion-proof port, and a flue gas temperature measuring device.

[0020] Process flow: Turn on the burner at the head of the purification incineration chamber to heat the regenerator to a high temperature of 1,000-1,100°C (conforming to the requirements of the incinerator technical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com