Integrated carbon capture carbon dioxide double-Brayton-cycle power generation system

A carbon dioxide, cycle power generation technology, applied in the steam generation method using heat carrier, steam generation, steam generation method, etc., to achieve the effect of reducing waste heat loss, reducing waste heat loss and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

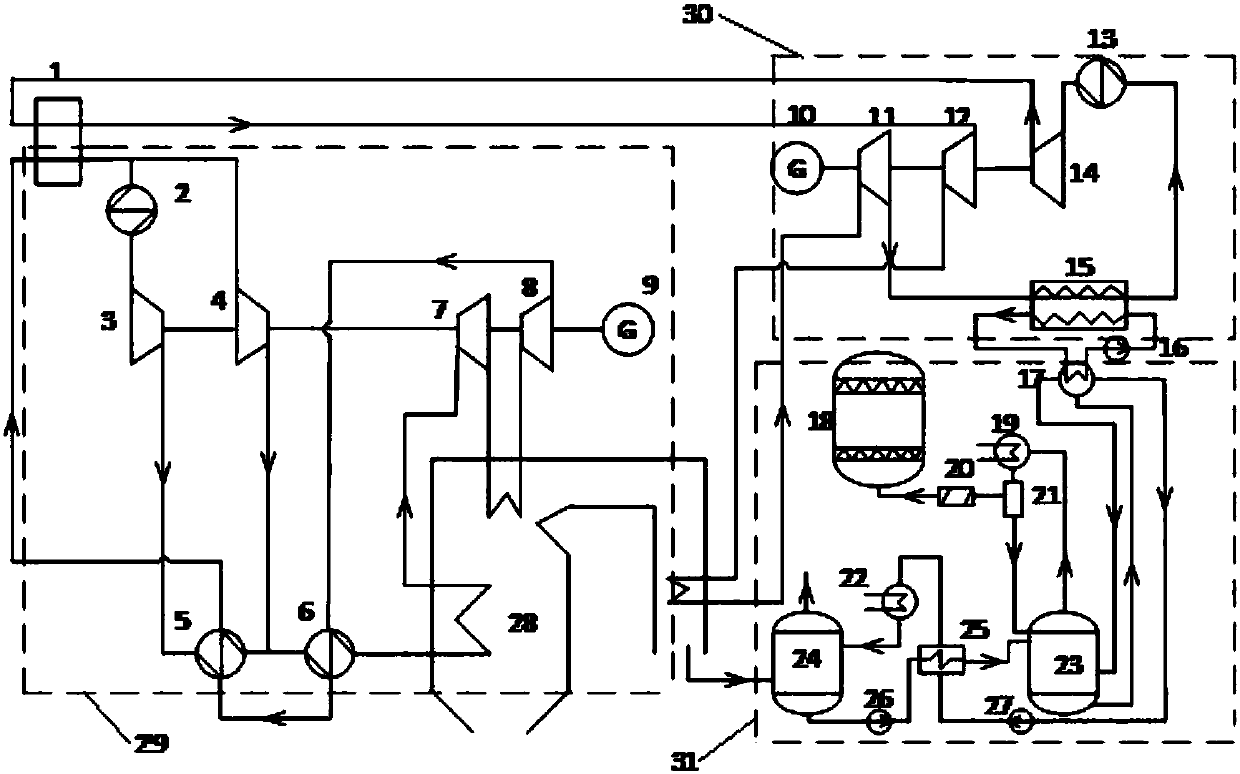

[0020] The invention relates to a carbon dioxide double Brayton cycle power generation system with integrated carbon capture, such as figure 1 As shown, it includes a main cycle 29 , a bottom cycle 30 , and a carbon capture system 31 .

[0021] The main cycle includes waste heat exchanger 1, precooler 2, main compressor 3, recompressor 4, low temperature regenerator 5, high temperature regenerator 6, high pressure CO 2 Turbine 7, low pressure CO 2 Turbine 8, main circulation generator 9 and boiler 28. Among them, the boiler is a coal-based boiler, the main compressor 3, the re-compressor 4, the high-pressure CO 2 Turbine 7, low pressure CO 2 The turbine 8 and the main cycle generator 9 are coaxially connected. The equipment is connected through the main circulation pipeline: the outlet of the tube side of the high-temperature regenerator 6 is wound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com