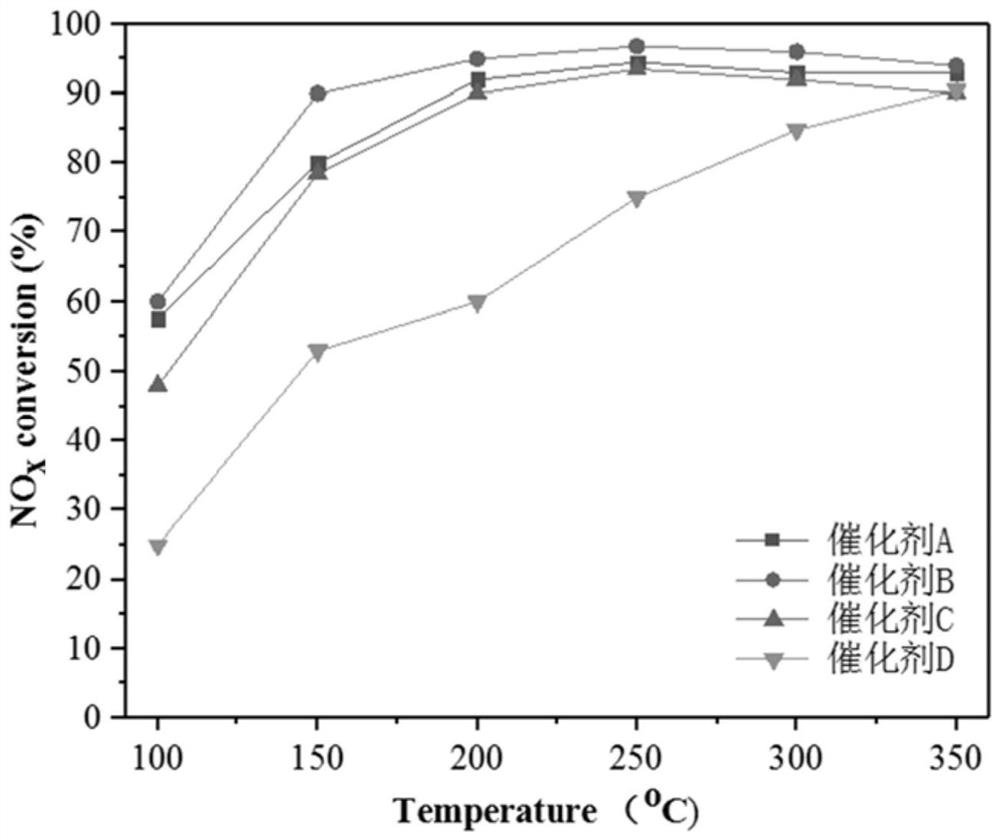

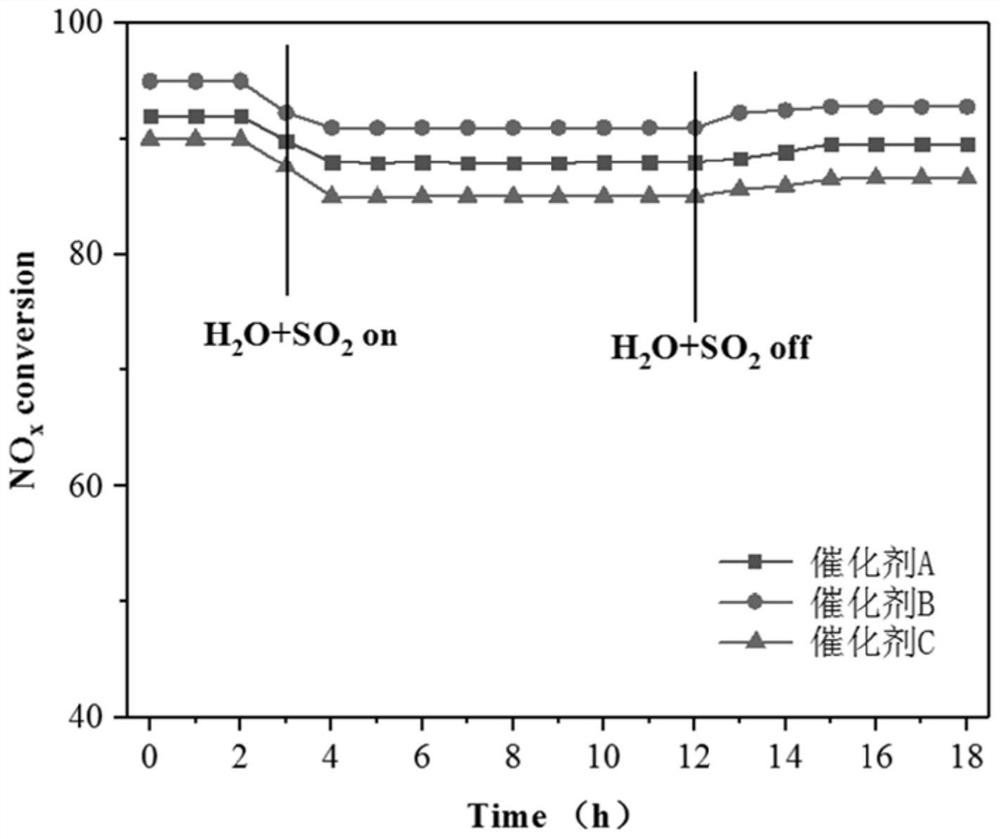

Wide-temperature-window efficient denitration catalyst as well as preparation method and application thereof

A denitrification catalyst, wide temperature technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of poisoning and deactivation catalyst use efficiency, low, etc., to improve low temperature denitrification activity and water resistance Sulfur performance, simple preparation process, and the effect of improving operating economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The NO catalyst for catalytic reduction made according to the present invention, wherein the molar ratio of active components is Mn, Dy, Al 2 o 3 The ratio of palygorskite to palygorskite is 1:0.05:0.04:1. Concrete preparation steps are as follows:

[0034] (1) Place palygorskite in deionized water and disperse to form a suspension slurry, stir at room temperature for 4h, and let stand for 1h to prepare a palygorskite slurry with a solid content of 4g / 100ml, which is recorded as solution 1;

[0035] (2) At room temperature, 2.5mol of AlCl 3 Place in a three-necked flask, add 1.5mol / L 125ml of NaOH solution dropwise, stir vigorously to form a milky white solution, then add 250ml of solution 1 to the above solution, stir vigorously at 80°C for 2h, then put the above The NaOH solution of 42ml is added in the solution until the pH value of the supernatant becomes neutral, and is recorded as solution 2;

[0036](3) Add 1 mol of manganese sulfate, 0.05 mol of dysprosium s...

Embodiment 2

[0040] The NO catalyst for catalytic reduction made according to the present invention, wherein the molar ratio of active components is Mn, Dy, Al 2 o 3 The ratio of palygorskite and palygorskite is 1:0.1:0.04:1. Concrete preparation steps are as follows:

[0041] (1) Place palygorskite in deionized water and disperse to form a suspension slurry, stir at room temperature for 4h, and let stand for 1h to prepare a palygorskite slurry with a solid content of 4g / 100ml, which is recorded as solution 1;

[0042] (2) At room temperature, 2.5mol of AlCl 3 Place in a three-necked flask, add 1.5mol / L 125ml of NaOH solution dropwise, stir vigorously to form a milky white solution, then add 250ml of solution 1 to the above solution, stir vigorously at 80°C for 2h, then put the above The NaOH solution of 42ml is added in the solution until the pH value of the supernatant becomes neutral, and is recorded as solution 2;

[0043] (3) 1mol of manganese sulfate, 0.1mol of dysprosium sulfate...

Embodiment 3

[0047] The NO catalyst for catalytic reduction made according to the present invention, wherein the molar ratio of active components is Mn, Dy, Al 2 o 3 The ratio of palygorskite to palygorskite is 1:0.2:0.04:1. Concrete preparation steps are as follows:

[0048] (1) Place palygorskite in deionized water and disperse to form a suspension slurry, stir at room temperature for 4h, and let stand for 1h to prepare a palygorskite slurry with a solid content of 4g / 100ml, which is recorded as solution 1;

[0049] (2) At room temperature, 2.5mol of AlCl 3 Place in a three-necked flask, add 1.5mol / L 125ml of NaOH solution dropwise, stir vigorously to form a milky white solution, then add 250ml of solution 1 to the above solution, stir vigorously at 80°C for 2h, then put the above The NaOH solution of 42ml is added in the solution until the pH value of the supernatant becomes neutral, and is recorded as solution 2;

[0050] (3) 1mol of manganese sulfate, 0.2mol of dysprosium sulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com