Reverse cycle dual push vanadium-nitrogen alloy production device and technology

A technology of vanadium nitrogen alloy and production equipment, which is applied in the field of vanadium nitrogen alloy, can solve the problems of low production efficiency, high construction cost and high energy consumption, and achieve the effects of improving production efficiency, saving labor costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

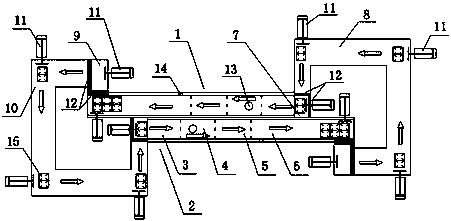

[0027] Such as figure 1 As shown, a reverse cycle double-push vanadium-nitrogen alloy production device includes a double-channel chamber, a pneumatic propulsion cylinder, a temperature control system, a furnace pressure control system and a nitrogen system. The double-channel chamber is equipped with a furnace pressure control system and a temperature control system. system, the dual-channel chamber body includes a channel chamber body A1 and a channel chamber body B2, the channel chamber body A1 and the channel chamber body B2 are arranged in reverse, and both of them are sequentially connected with a preheating section 3, a heating section 4, and carbon nitriding Section 5 and cooling section 6, the preheating section 3 is connected to the feed seal chamber 7, the feed seal chamber 7 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com