Waste heat collecting device used for discharging end of ultra high temperature vertical kiln

A waste heat collection and discharge end technology, applied in the field of high-temperature shaft kiln supporting devices, can solve the problems of low heat collection efficiency, easy oxidation and erosion, short service life, etc., and achieves good energy saving effect, quick and easy assembly, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

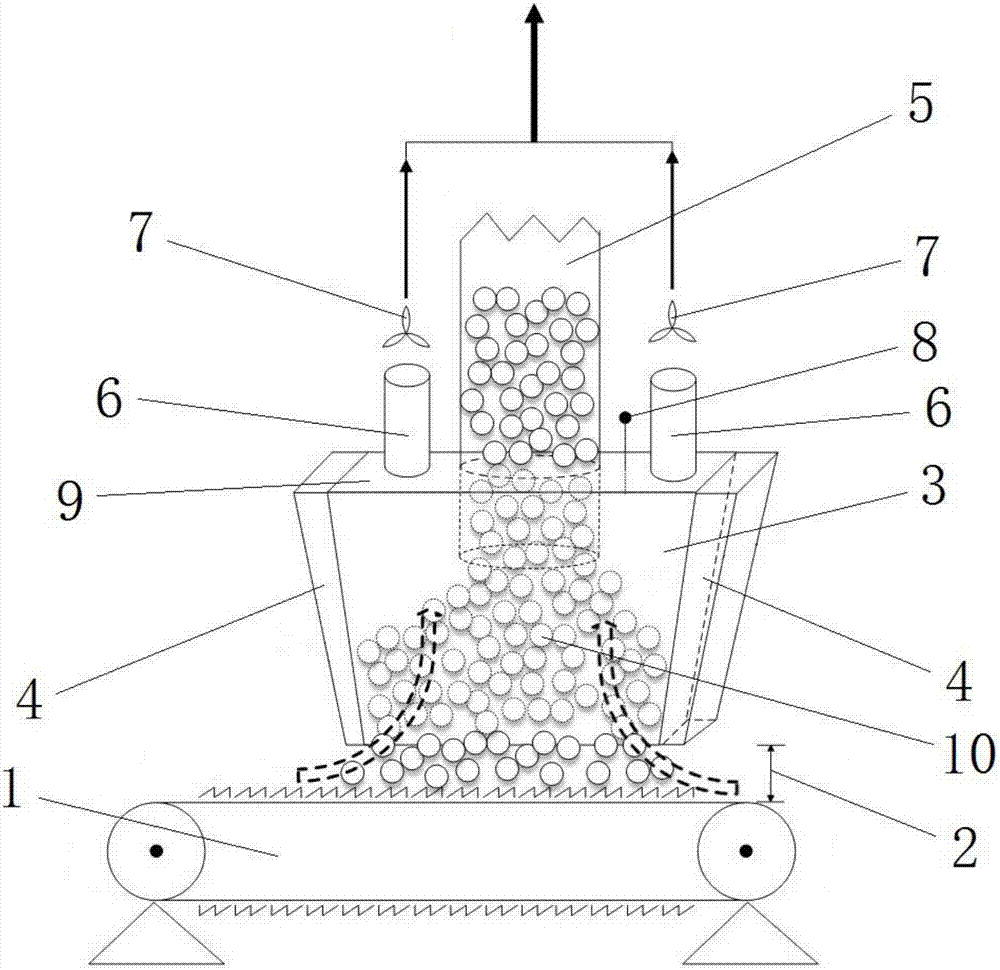

[0032] A waste heat collection device for the discharge end of an ultra-high temperature shaft kiln, including a conveyor 1, a gap 2, a shell 3, a heat insulation layer 4, a shaft kiln discharge pipe 5, a waste heat air duct 6, a fan 7, and a temperature sensor 8 , end cover 9, wherein the shell 3 is located above the conveyor 1, there is a gap 2 between the shell 3 and the conveyor 1, the lower port of the shell 3 is open, and the upper port is connected to the end cover 9, the shaft kiln discharge pipe 5 and the waste heat air duct 6 are respectively connected to the end cover 9, the lower port of the shaft kiln discharge pipe 5 and the lower port of the waste heat air duct 6 all extend into the inside of the housing 3, and the outer periphery of the housing 3 The heat insulation layer 4 is fixedly connected, the fan 7 is fixedly connected to the upper port of the waste heat air duct 6, the temperature sensor 8 is fixedly connected to the end cover 9, and the temperature prob...

Embodiment 2

[0043] A waste heat collection device for the discharge end of an ultra-high temperature shaft kiln, including a conveyor 1, a gap 2, a shell 3, a heat insulation layer 4, a shaft kiln discharge pipe 5, a waste heat air duct 6, a fan 7, and a temperature sensor 8 , end cover 9, wherein the shell 3 is located above the conveyor 1, there is a gap 2 between the shell 3 and the conveyor 1, the lower port of the shell 3 is open, and the upper port is connected to the end cover 9, the shaft kiln discharge pipe 5 and the waste heat air duct 6 are respectively connected to the end cover 9, the lower port of the shaft kiln discharge pipe 5 and the lower port of the waste heat air duct 6 all extend into the inside of the housing 3, and the outer periphery of the housing 3 The heat insulation layer 4 is fixedly connected, the fan 7 is fixedly connected to the upper port of the waste heat air duct 6, the temperature sensor 8 is fixedly connected to the end cover 9, and the temperature prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com