A wide temperature window denitration catalyst and its preparation method and application

A denitration catalyst, wide temperature technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of catalyst poisoning, short catalyst service life, etc., achieve easy operation, low preparation cost, and reduce waste heat. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

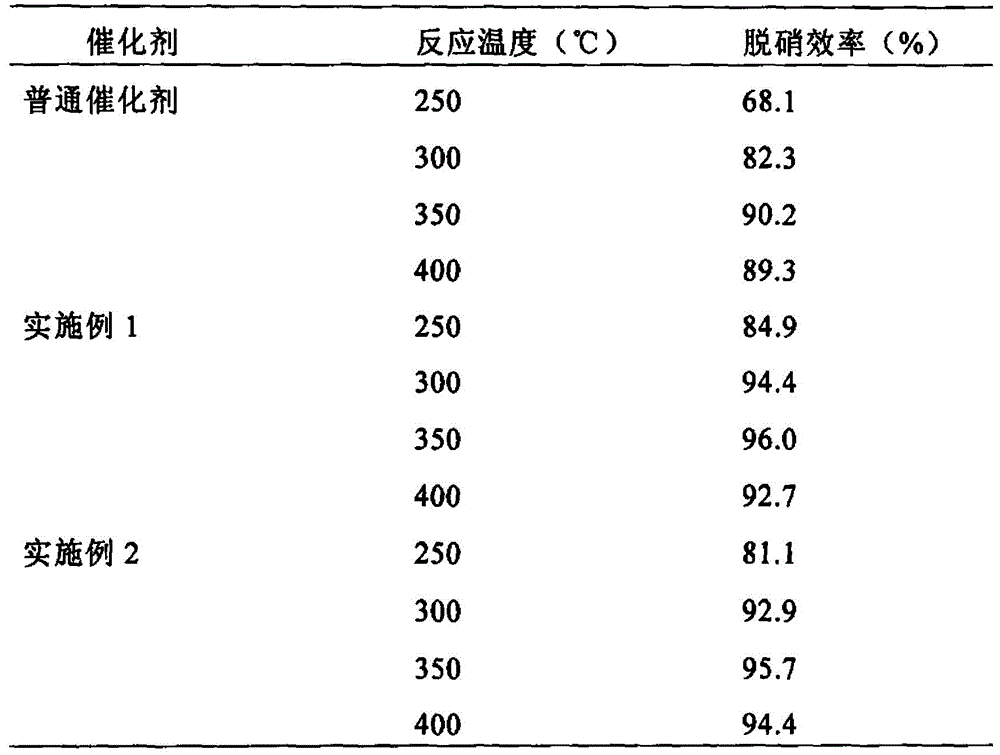

Embodiment 1

[0042] A Wide Temperature Window Denitration VxOy-CeO 2 -ZrO2 Catalyst A is calculated according to the molar ratio of the contained metal elements V, Ce, and Zr, wherein V:Ce:Zr is 0.2:1:1. The preparation method of this catalyst comprises the steps:

[0043] (1) 14.47gCe(NO 3 ) 3 ·6H 2 O and 14gZr(NO 3 ) 4 ·5H 2 O is dissolved in deionized water, and a polytetrafluoroethylene stirring rod is used at a water temperature of 60-70°C, and the stirring rate is controlled at 600-1000rpm. During the stirring process, ammonia water with a concentration of 20% is slowly dripped in as a precipitant to make the pH of the mixture The value reached between 10-11 and was left to stand for 2-3 hours to obtain complete precipitation.

[0044] The amount of soluble cerium salt, soluble zirconium salt, ammonia water and deionized water used in the above preparation process is calculated by molar ratio, that is, cerium in soluble cerium salt: zirconium in soluble zirconium salt: ammonia...

Embodiment 2

[0054] A Wide Temperature Window Denitration VxOy-CeO 2 -ZrO 2 Catalyst A, calculated by the mol ratio of contained metal element V, Ce, Zr, wherein V: Ce: Zr is 0.2: 1: 1 The preparation method of this catalyst comprises the steps:

[0055] (1) 14.47gCe(NO 3 ) 3 ·6H 2 O and 14gZr(NO 3 ) 4 ·5H 2 O is dissolved in deionized water, and a polytetrafluoroethylene stirring rod is used at a water temperature of 60-70°C, and the stirring rate is controlled at 600-1000rpm. During the stirring process, ammonia water with a concentration of 20% is slowly dripped in as a precipitant to make the pH of the mixture The value reached between 10-11 and was left to stand for 2-3 hours to obtain complete precipitation.

[0056] The amount of soluble cerium salt, soluble zirconium salt, ammonia water and deionized water used in the above preparation process is calculated by molar ratio, that is, cerium in soluble cerium salt: zirconium in soluble zirconium salt: ammonia in ammonia water: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com