Micro parallel plate burner with preheating channel

A technology of preheating channels and parallel plates, which is applied in the direction of burners, gas fuel burners, and combustion methods, and can solve problems such as poor matching between radiators and photocells, short residence time of mixed gas, and low overall conversion efficiency. , to achieve the effect of improving photoelectric conversion efficiency, improving energy conversion efficiency, and stabilizing combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

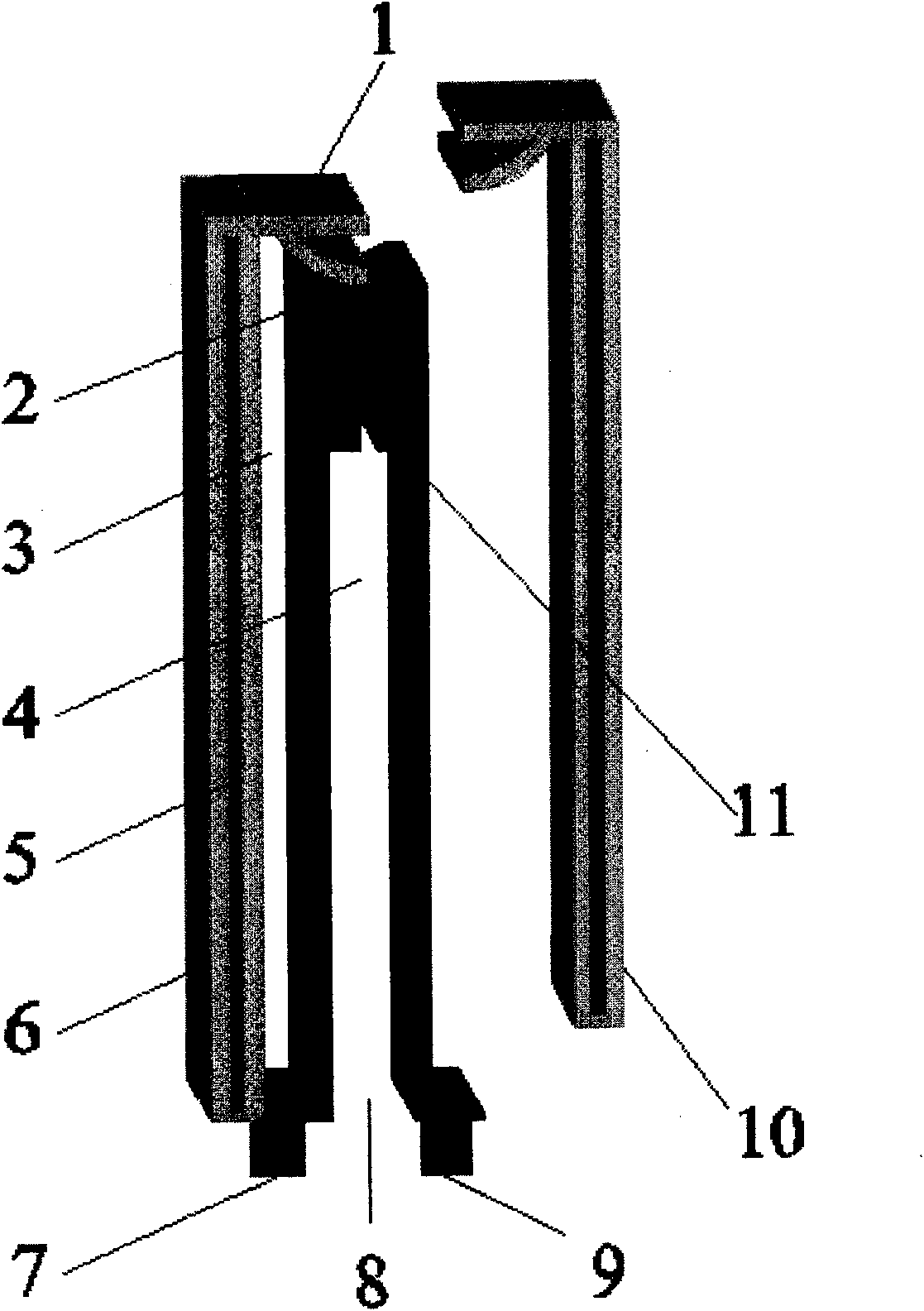

[0011] In the present invention, the quartz glass shield is an integration of three parts. The boss shield of the uppermost part and the glass on the left and right sides are both double-layered in the middle vacuum structure. The overall height of the burner is 10.8mm and the width is 3.8mm. The length is 8mm, the single-layer glass thickness is 0.2mm, and the vacuum width is also 0.2mm; the material of the combustion chamber is SiC ceramics with strong high temperature resistance. The physical properties of SiC used are shown in the table below. The height of the radiation surface outside the combustion chamber is 10mm, the length is 8mm, the height of the combustion zone is 8mm, the width is 1mm, and the wall thickness is 0.2mm; the height of the mixing zone is 2mm, the width is 0.2mm, and the corresponding wall thickness is 0.6mm; The width of the hot zone channel is 0.6mm, and the diameter of the air inlets at both ends is 0.4mm. Under normal temperature and a standard atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com