300MW circulating fluidized bed boiler island

A circulating fluidized bed, 1.300MW technology, applied in the field of 300MW circulating fluidized bed boiler power generation engineering device, can solve the problems of long heating time, boiler wear, blockage, etc., to suppress the generation of CO, reduce the temperature of flue gas, and economical sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

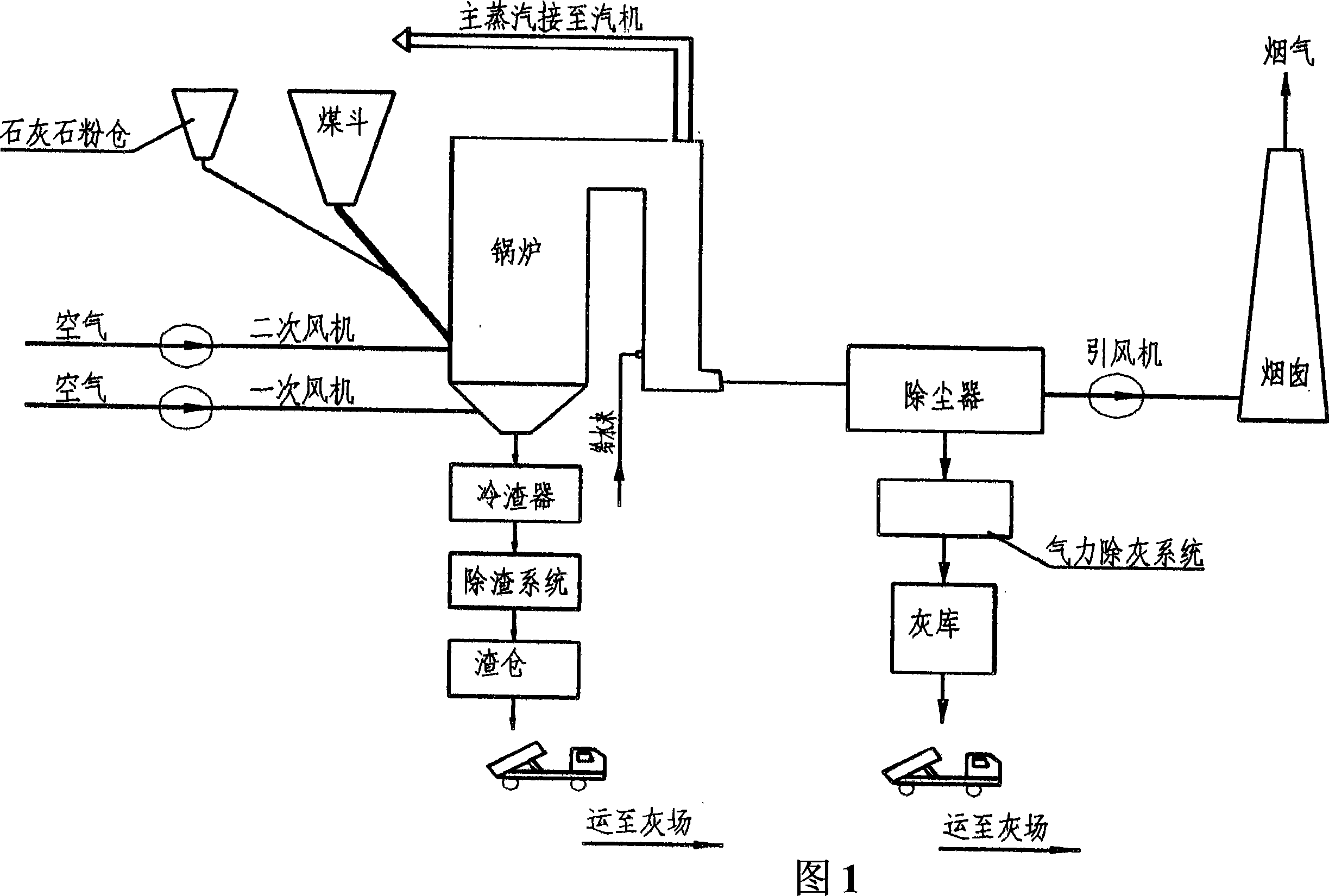

Image

Examples

Embodiment

[0017] Embodiment: The engineering coal is low calorific value lignite, which has high water content, low calorific value and medium sulfur content. Its main characteristics are easy to catch fire, easy to coke, difficult to burn out, weak abrasiveness, and high content of calcium oxide in the ash (GaO=47.75%).

[0018] The combustion method of the circulating fluidized bed boiler is low-temperature fluidized combustion, which can not only desulfurize but also denitrate, and can also inhibit the formation of CO. At the same time, it can also greatly reduce the flue gas temperature and reduce the heat loss of the boiler exhaust, thereby further improving the boiler thermal efficiency.

[0019] According to the actual operation, the equivalent available coefficients of #1 and 2 boilers are 92.63% and 94.6% respectively; the measured average values of thermal efficiency of #1 and 2 boilers are 93.26% and 93.56% respectively; the environmental protection emission values of boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com