Device and method for detecting sulfur trioxide in flue gas on line

A sulfur trioxide and detection device technology, which is applied in measuring devices, sampling devices, and material analysis by observing the impact on chemical indicators, etc., can solve the problems of inability to realize online measurement, high material accuracy requirements, and inconvenient portability of the device , to achieve the effects of short measurement time, reduced heat loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

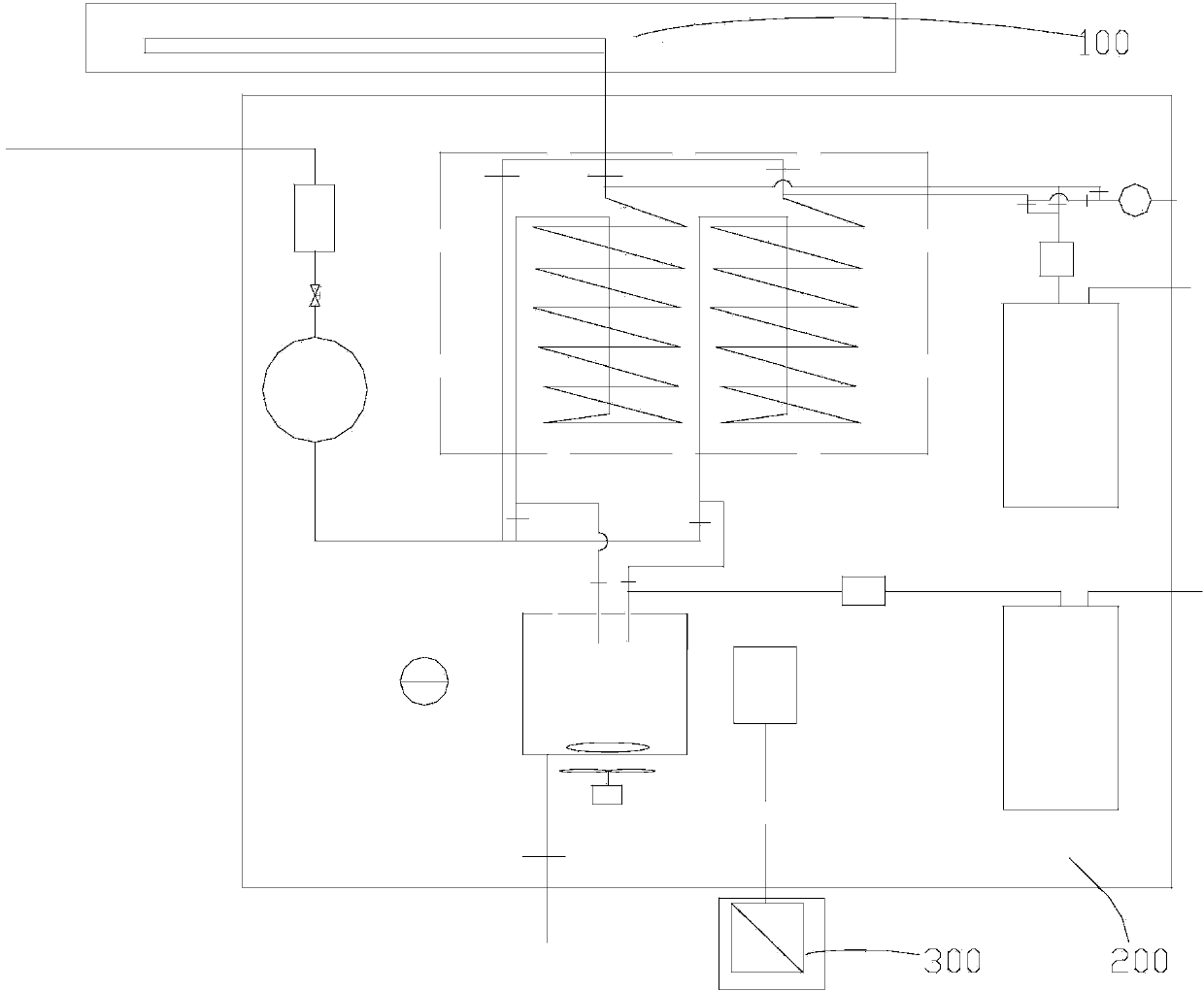

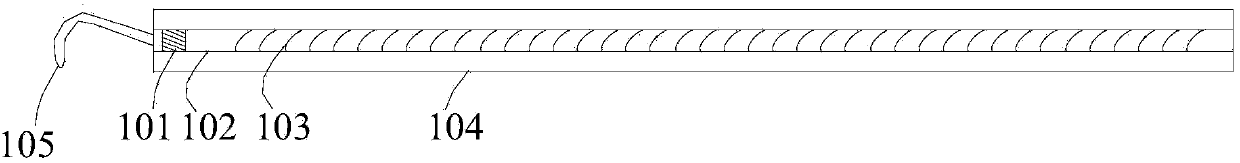

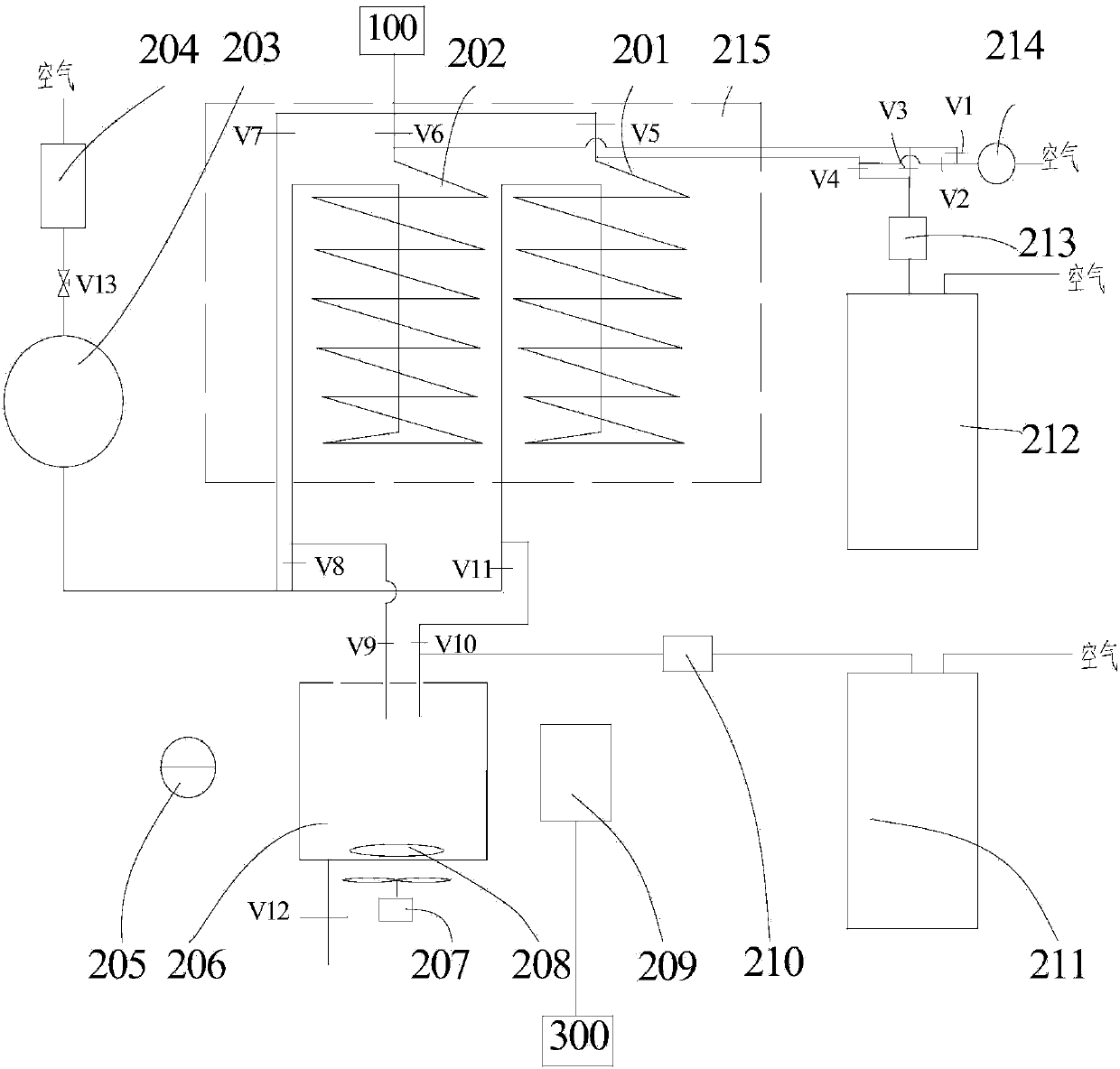

Embodiment 1

[0081] Using the device and measuring method of the present invention to detect SO in flue gas before denitrification in a certain power plant 3 concentration. The layout of measuring points of denitrification SCR system in a power plant is as follows: Figure 5 As shown, the SCR system inlet measuring point, the device of the present invention is arranged on the horizontal flue at the inlet of the economizer 400 (position 401), and the measuring holes are evenly distributed. Replace the quartz wool in the filter chamber 101 before the test, fill the first solution tank 212 with an aqueous solution with an isopropanol concentration of 80%, and fill the second solution tank 211 with thorium reagent and BaCl 2 solution, the wavelength of the light source is 530nm, and the SO at the position of the power plant is detected 3 The average concentration under this working condition is 14.6mg / m 3 , using the method in "Measurement Test Method for Performance of Coal-fired Flue Gas ...

Embodiment 2

[0083] Using the device and measuring method of the present invention to detect SO in flue gas after denitrification in a certain power plant 3 concentration. The layout of measuring points of denitrification SCR system in a power plant is as follows: Figure 5 As shown, the measuring point at the outlet of the SCR system, the device of the present invention is arranged on the horizontal flue at the outlet of the economizer 400 (position 402), and the measuring holes are evenly distributed. Before the test, replace the quartz wool in the filter chamber 101. In the first solution tank 212, it is an aqueous solution with an isopropanol concentration of 80%, and in the second solution tank 211, it is filled with thorium reagent and BaCl 2 solution, the wavelength of the light source is 530nm, and the SO at the position of the power plant is detected 3 The average concentration under this working condition is 42.1mg / m 3 , use the method in "Measurement Test Method for Performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com