Denitration of non-selective catalytic reducing smoke

A non-selective, denitrification technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of reduced boiler thermal efficiency, increased exhaust heat loss, and increased production volume, reducing operating costs and reducing costs. The effect of flue gas denitration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

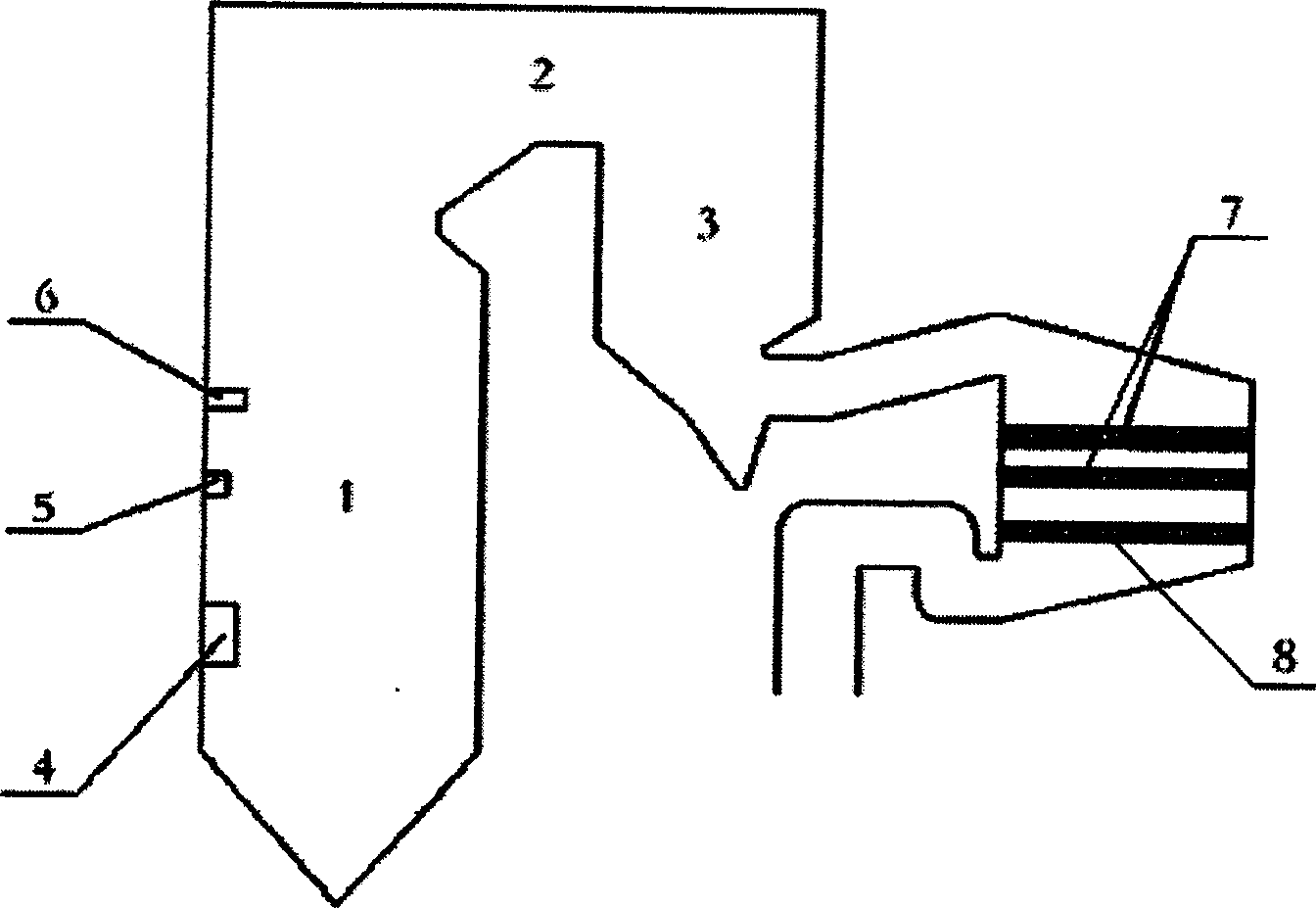

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The denitrification device is composed of a boiler furnace 1, a horizontal flue 2, a tail flue 3, and a catalytic reactor 9 connected in series. In the boiler furnace 1, a burner 4, an exhaust air inlet 5, and fine coal powder are arranged in sequence from bottom to top. The injection inlet 6 is provided with 7 layers of NSCR catalysts and 8 layers of oxidation catalysts in the catalytic reactor 9 at the rear of the tail flue 3 , and the oxidation catalysts 8 are arranged downstream of the NSCR catalysts 7 . The fuel is burned in the furnace 1 of the boiler, and 100% of the fuel required by the coal-fired unit is added to the position of the burner 4, and the equivalent air coefficient required by 0.75-85% of the fuel is added according to the specific coal type (mainly distinguished by volatile content) , the rest of the air required for combustion is added at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com