A high-efficiency atomization combustion system and method for an industrial furnace

A technology of industrial furnaces and combustion systems, applied in the field of energy and environment, can solve problems affecting production efficiency, sintering and carbon deposition at the outlet of burner nozzles, etc., achieve low maintenance costs, increase combustion temperature, and improve fuel combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

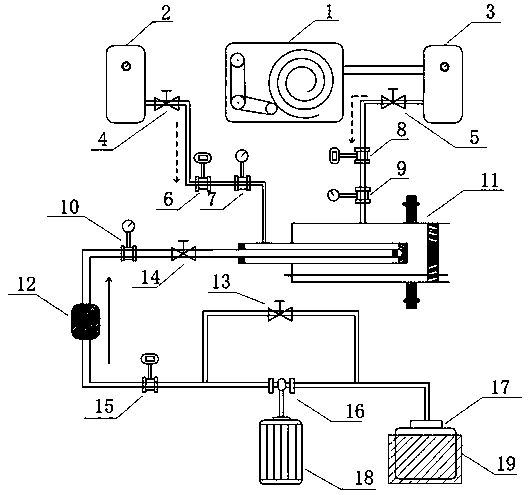

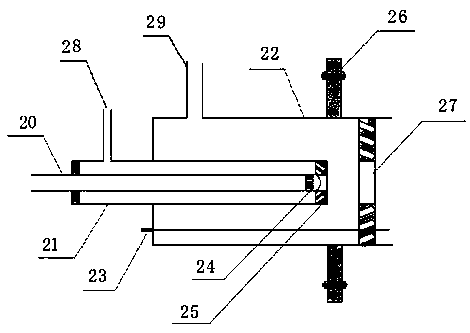

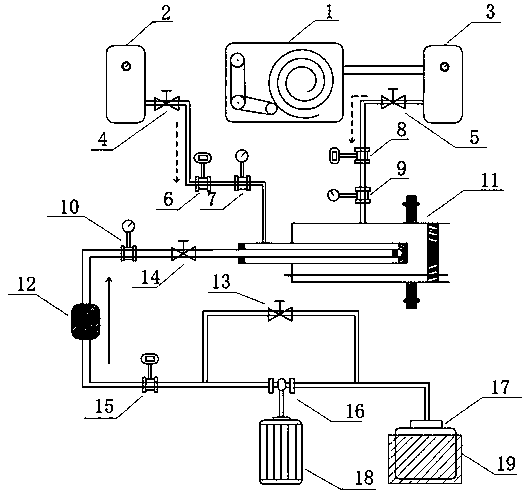

[0029] Such as figure 1 and 2 As shown, the industrial furnace high-efficiency atomization combustion system based on high-viscosity biomass fuel oil includes oxygen generator 1, nitrogen storage tank 2, oxygen storage tank 3, pressure regulating valve I4, pressure regulating valve II5, digital gas flow rate Gauge Ⅰ6, barometer Ⅰ7, digital gas flowmeter Ⅱ8, barometer Ⅱ9, oil pressure gauge 10, burner group 11, filter 12, circulating oil valve 13, pressure regulating valve Ⅲ14, digital liquid flowmeter 15, oil pump 16. Fuel tank 17, motor 18 and steam heating device 19, burner group 11 includes fuel oil passage 20, high-pressure nitrogen passage 21, high-pressure oxygen passage 22, electronic ignition needle 23, fuel nozzle 24, first-stage nitrogen atomization swirl plate 25 , mounting flange 26, secondary oxygen atomizing swirl piece 27, nitrogen inlet 28 and oxygen inlet 29;

[0030] The fuel oil passage 20, the high-pressure nitrogen passage 21, and the high-pressure oxyge...

Embodiment 2

[0041] Such as figure 1 and 2 As shown, the industrial furnace high-efficiency atomization combustion system based on high-viscosity biomass fuel oil includes oxygen generator 1, nitrogen storage tank 2, oxygen storage tank 3, pressure regulating valve I4, pressure regulating valve II5, digital gas flow rate Gauge Ⅰ6, barometer Ⅰ7, digital gas flowmeter Ⅱ8, barometer Ⅱ9, oil pressure gauge 10, burner group 11, filter 12, circulating oil valve 13, pressure regulating valve Ⅲ14, digital liquid flowmeter 15, oil pump 16. Fuel tank 17, motor 18 and steam heating device 19, burner group 11 includes fuel oil passage 20, high-pressure nitrogen passage 21, high-pressure oxygen passage 22, electronic ignition needle 23, fuel nozzle 24, first-stage nitrogen atomization swirl plate 25 , mounting flange 26, secondary oxygen atomizing swirl piece 27, nitrogen inlet 28 and oxygen inlet 29;

[0042] The fuel oil passage 20, the high-pressure nitrogen passage 21, and the high-pressure oxyge...

Embodiment 3

[0053] Such as figure 1 and 2 As shown, the industrial furnace high-efficiency atomization combustion system based on high-viscosity biomass fuel oil includes oxygen generator 1, nitrogen storage tank 2, oxygen storage tank 3, pressure regulating valve I4, pressure regulating valve II5, digital gas flow rate Gauge Ⅰ6, barometer Ⅰ7, digital gas flowmeter Ⅱ8, barometer Ⅱ9, oil pressure gauge 10, burner group 11, filter 12, circulating oil valve 13, pressure regulating valve Ⅲ14, digital liquid flowmeter 15, oil pump 16. Fuel tank 17, motor 18 and steam heating device 19, burner group 11 includes fuel oil passage 20, high-pressure nitrogen passage 21, high-pressure oxygen passage 22, electronic ignition needle 23, fuel nozzle 24, first-stage nitrogen atomization swirl plate 25 , mounting flange 26, secondary oxygen atomizing swirl piece 27, nitrogen inlet 28 and oxygen inlet 29;

[0054] The fuel oil passage 20, the high-pressure nitrogen passage 21, and the high-pressure oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com