Apparatus and Methods For Providing Uniformly Volume Distributed Combustion of Fuel

a technology of uniform volume distribution and apparatus, applied in the direction of combustion types, combustion methods, lump and pulverulent fuel, etc., can solve the problems of high combustion rate of fuel, low carbon monoxide content and nitric oxide of exhaust, and low oxygen content, so as to improve flameless oxidation of primary fuel, reduce exhaust gas toxicity, and increase the completeness of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

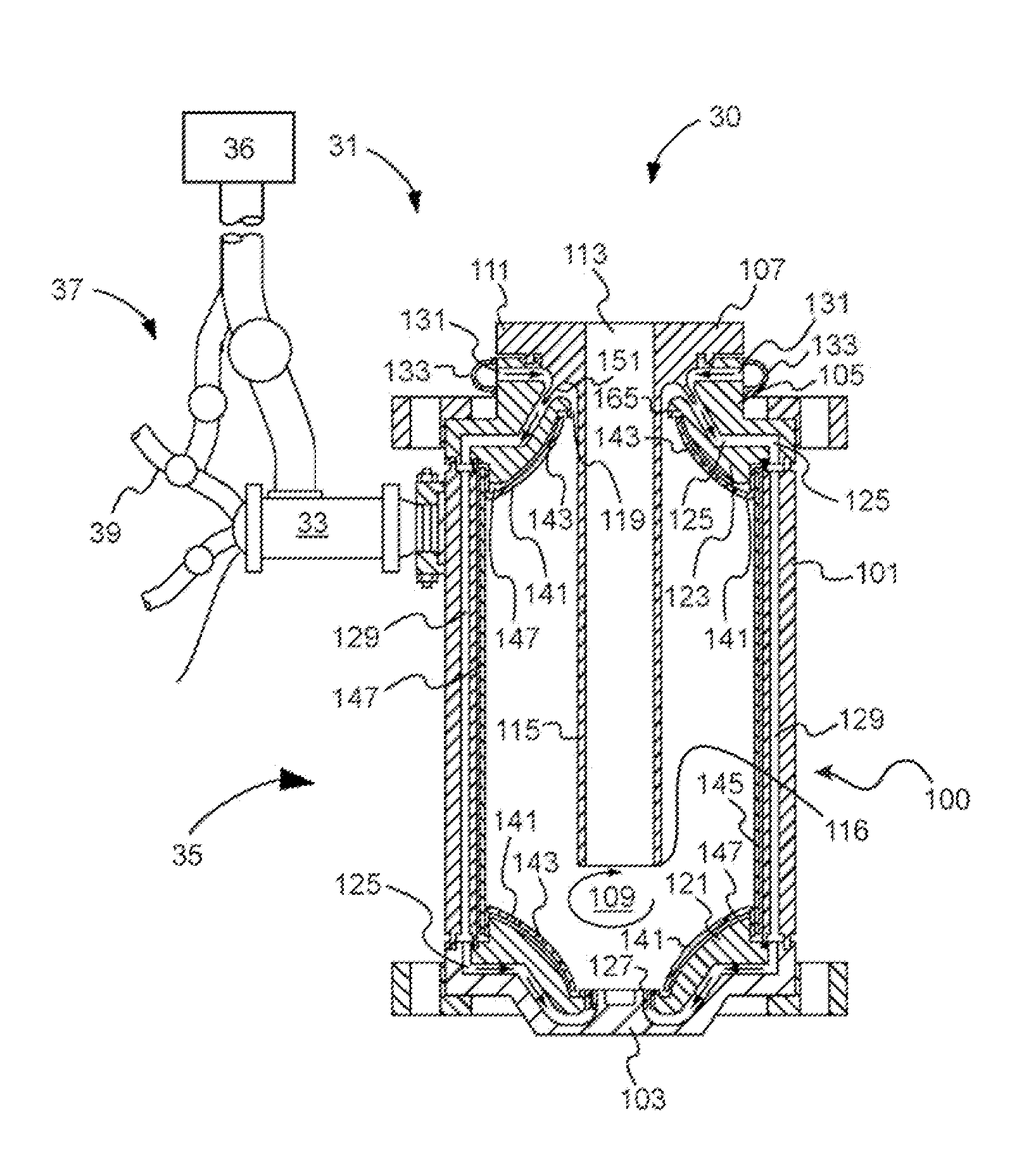

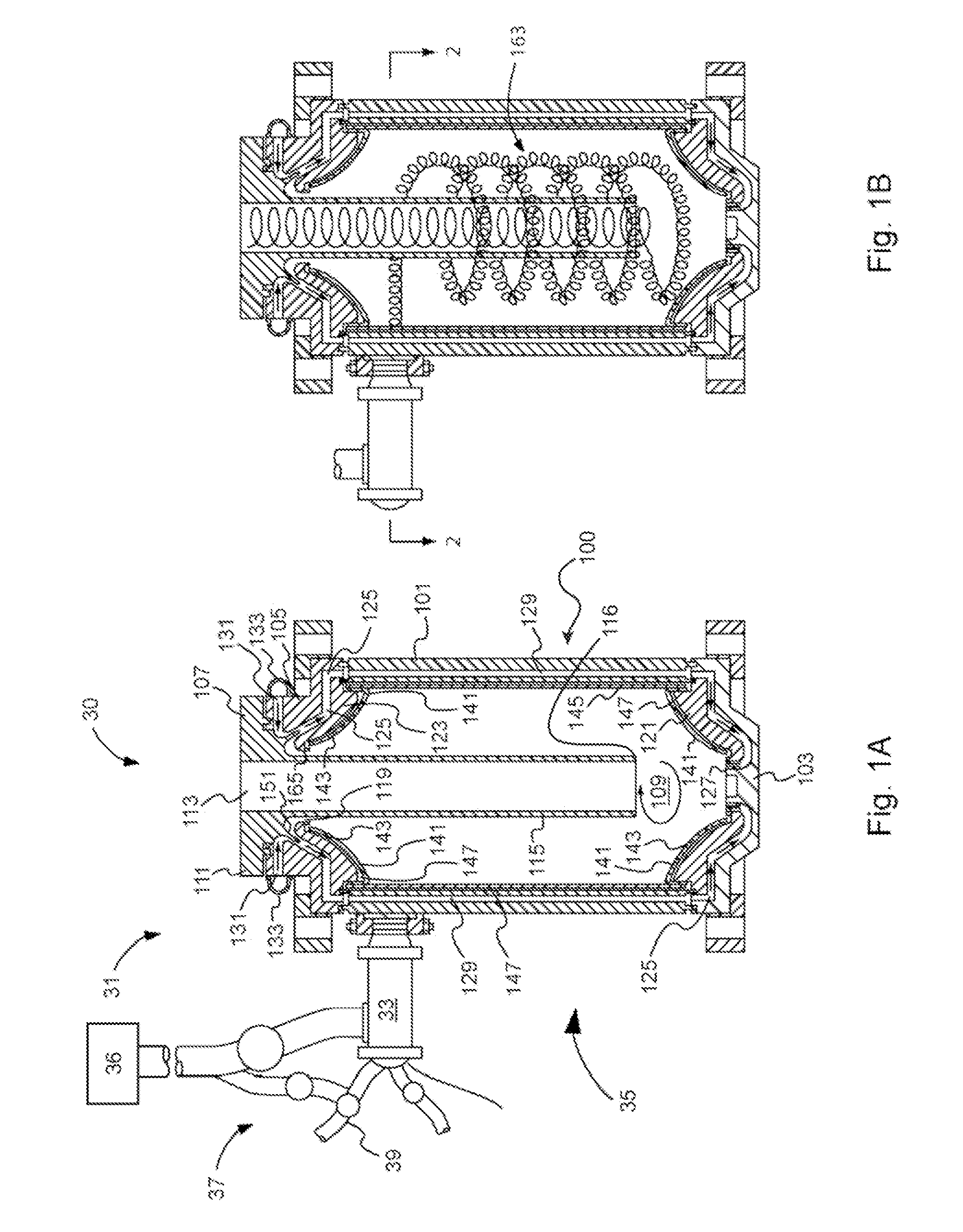

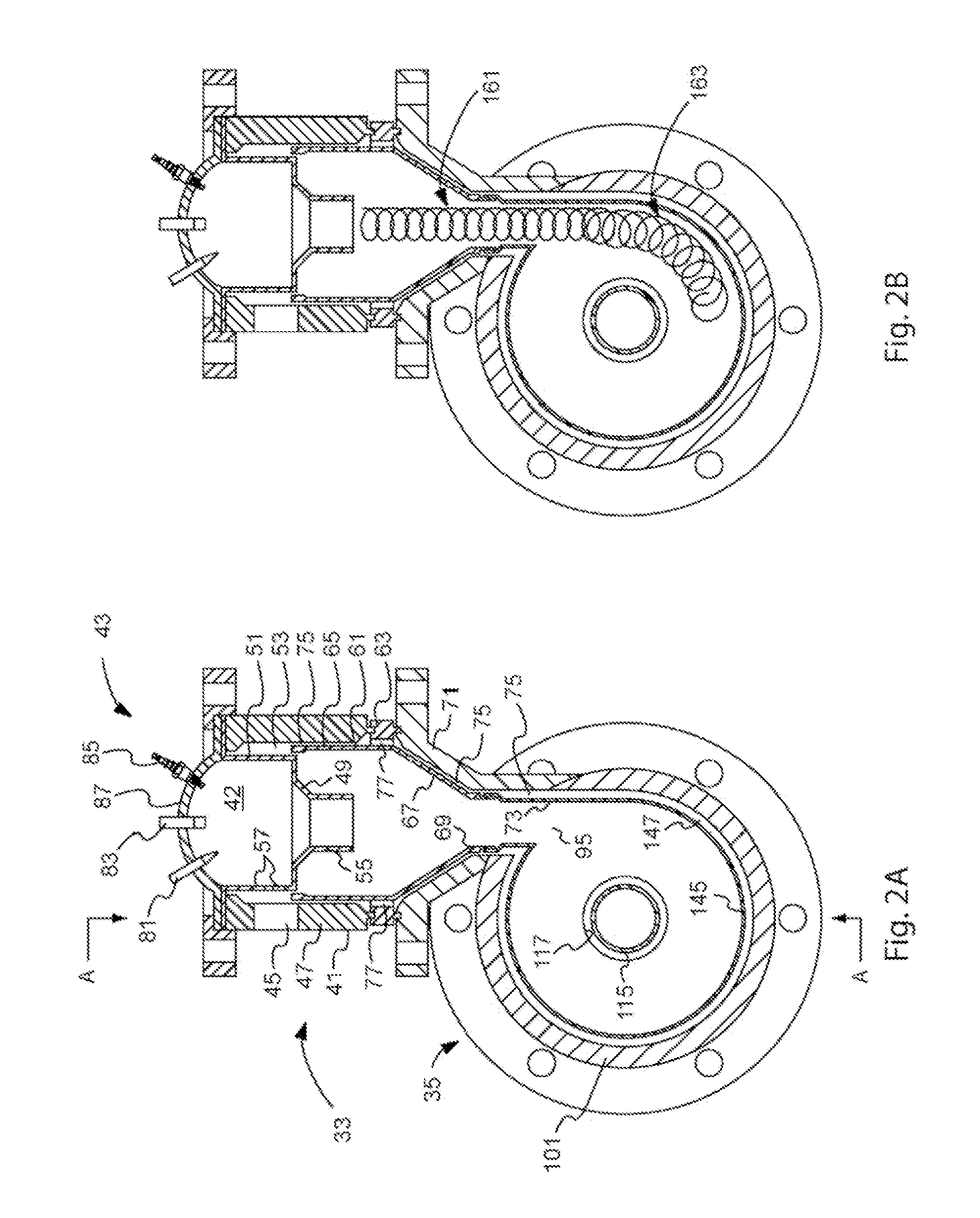

[0042]The present invention will now be described more fully hereinafter with reference to the accompanying drawings, which illustrate embodiments of the invention. This invention may, however, be embodied in many different forms and should not be construed as limited to the illustrated embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. Like numbers refer to like elements throughout.

[0043]FIGS. 1A-11 illustrate a system 30 including combustor apparatus 31 and methods which improve upon the vortex combustion chamber and precombustion chamber of the Jirnov engine described in U.S. Pat. No. 5,839,270 by Jirnov et al., titled “Sliding-Blade Rotary Air-Heat Engine with Isothermal Compression of Air,” to more efficiently accommodate use of more viscous fuels. According to various embodiments of the present invention, the combustor apparatus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com