Heat-conducting oil boiler waste heat power generation system

A heat-conducting oil boiler and waste heat power generation technology, which is applied to steam boilers, heat storage heaters, steam generation methods using heat carriers, etc., can solve the problem that the waste heat of heat-conducting oil boiler flue gas has not been fully recovered and utilized, and achieve improved fuel efficiency. Combustion efficiency, improving waste heat recovery rate, and improving the effect of waste heat recovery utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

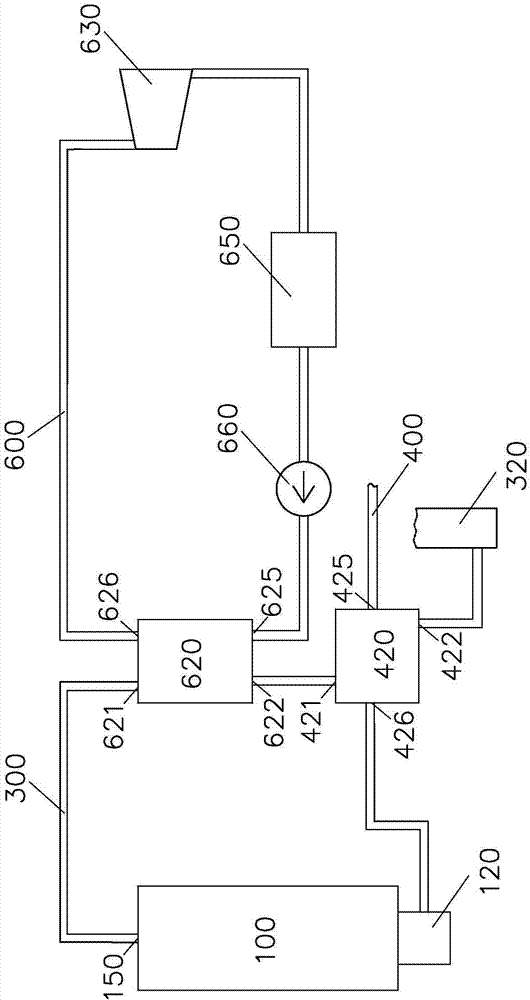

[0023] Please refer to figure 1 , according to an embodiment of the present invention, the thermal oil boiler waste heat power generation system includes: a furnace body 100, a nozzle 120, a flue gas pipeline 300, a chimney 320, an air pipeline 400, an air preheater 420, a water vapor cycle power generation circuit 600, Steam generator 620 , steam turbine 630 , screw generator 650 and water pump 660 .

[0024] The furnace body 100 is provided with a furnace (not shown) for heating the heat transfer oil. The nozzle 120 is arranged on one end wall of the furnace body 100, and is used for injecting fuel and combustion-supporting air into the furnace for burning and releasing heat.

[0025] The flue gas pipe 300 is connected to the other end wall of the furnace body 100 for discharging the flue gas from the furnace body flue gas outlet 150 to the chimney 320 .

[0026] The air pipeline 400 is connected to the nozzle 120, and is used for delivering the combustion air to the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com