Apparatus for automatic control of exhaust pressure of an internal combustion engine

an internal combustion engine and automatic control technology, applied in the direction of engine controllers, machines/engines, mechanical apparatus, etc., can solve the problems of increasing the exhaust pressure of the engine, consuming more fuel than is necessary, reducing the output of the engine, etc., to increase the exhaust pressure, reduce the exhaust fume, and increase the efficiency of fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

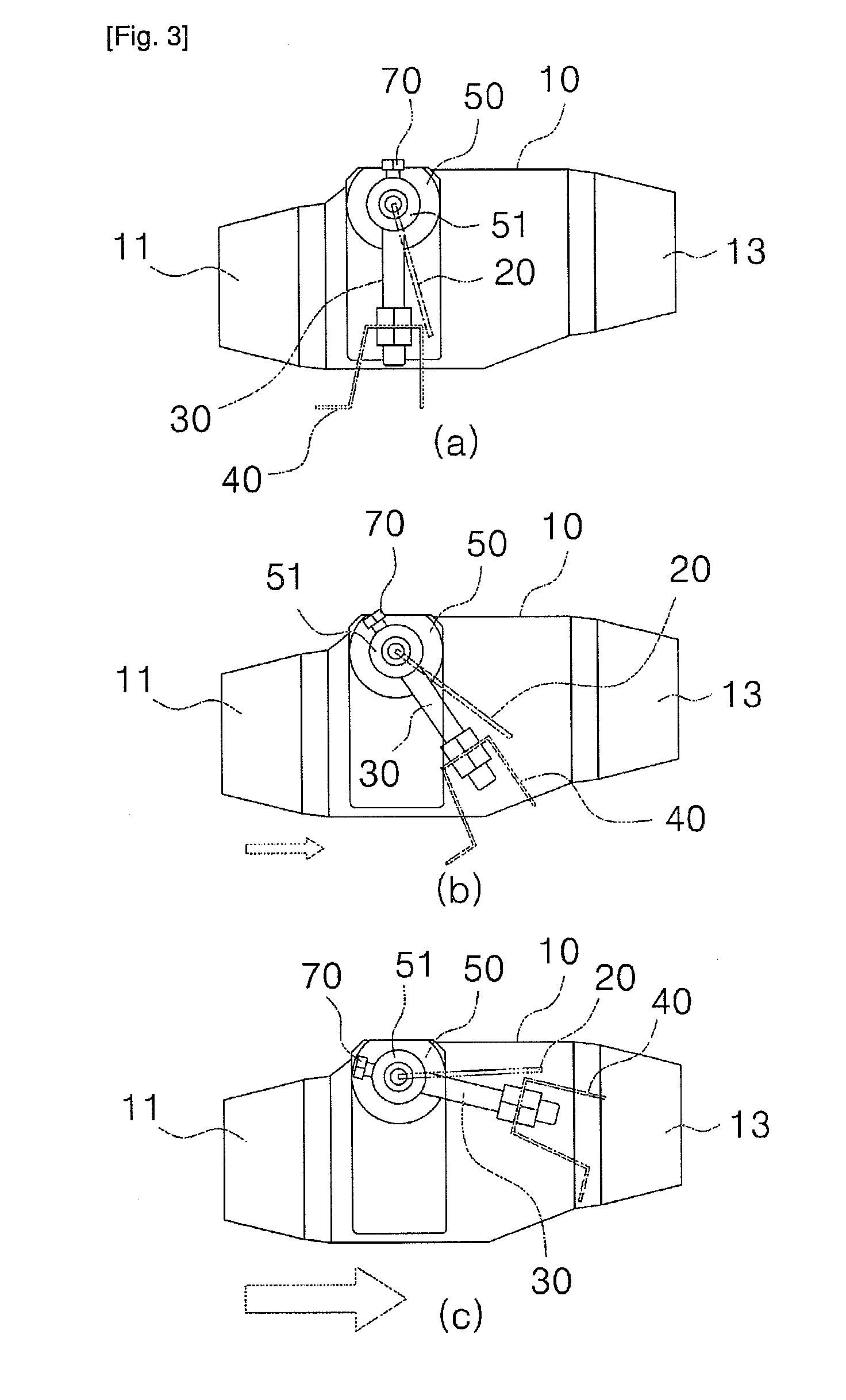

[0022]An apparatus for automatic control of exhaust pressure of an internal combustion engine according to an embodiment of the present invention is designed to automatically control the amount by which the exhaust passage is opened and closed according to the exhaust pressure, automatically increasing the exhaust pressure during low-speed rotation and lowering the exhaust pressure during high-speed rotation, and thus effectively responding to the valve overlap.

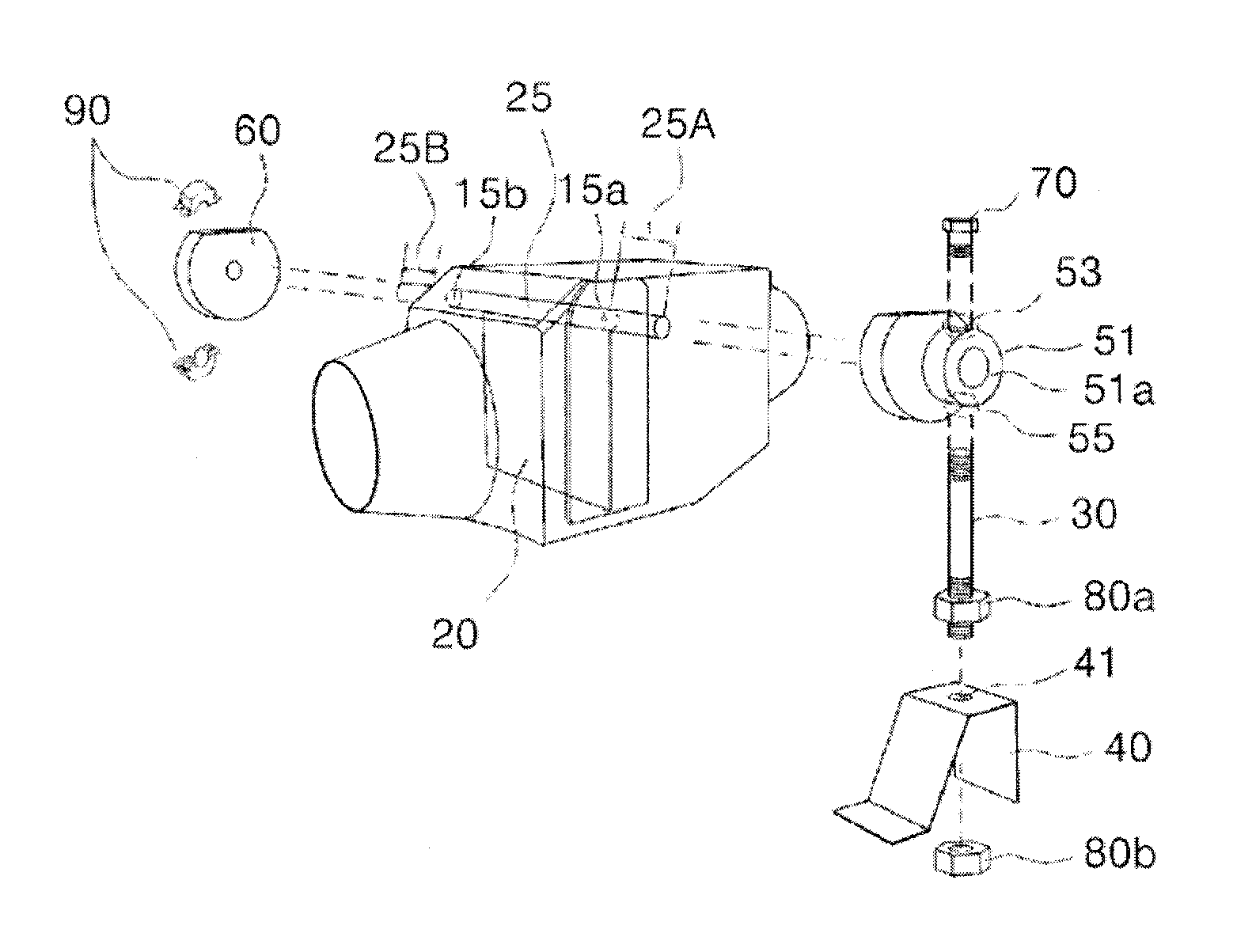

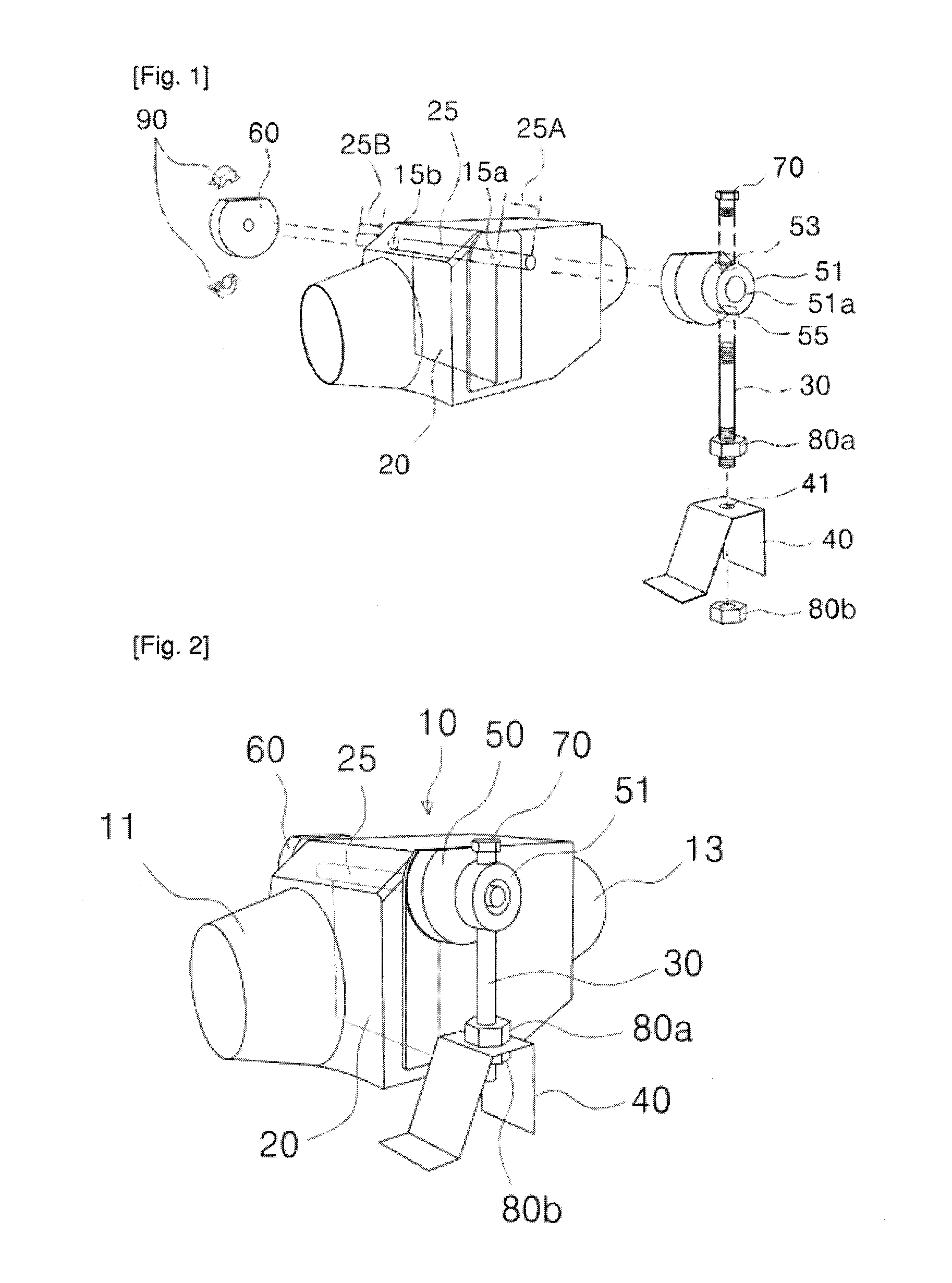

[0023]FIG. 1 is an exploded perspective view showing the structure of an apparatus for automatic control of exhaust pressure of an internal combustion engine according to an embodiment of the present invention, and FIG. 2 is an assembly drawing of FIG. 1.

[0024]With reference to FIGS. 1 and 2, the apparatus for automatic control of exhaust pressure according to an embodiment of the present invention includes: a body 10; a pressure control plate 20; a controlling pendulum 30; and a pendulum blade 40.

[0025]A core concept of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com