Efficient waste-heat-recycle power generation device for gas turbine and control method

A gas turbine and waste heat recovery technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as energy waste and environmental pollution, and achieve the effects of reducing heat exchange area, reducing environmental pollution, and saving metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

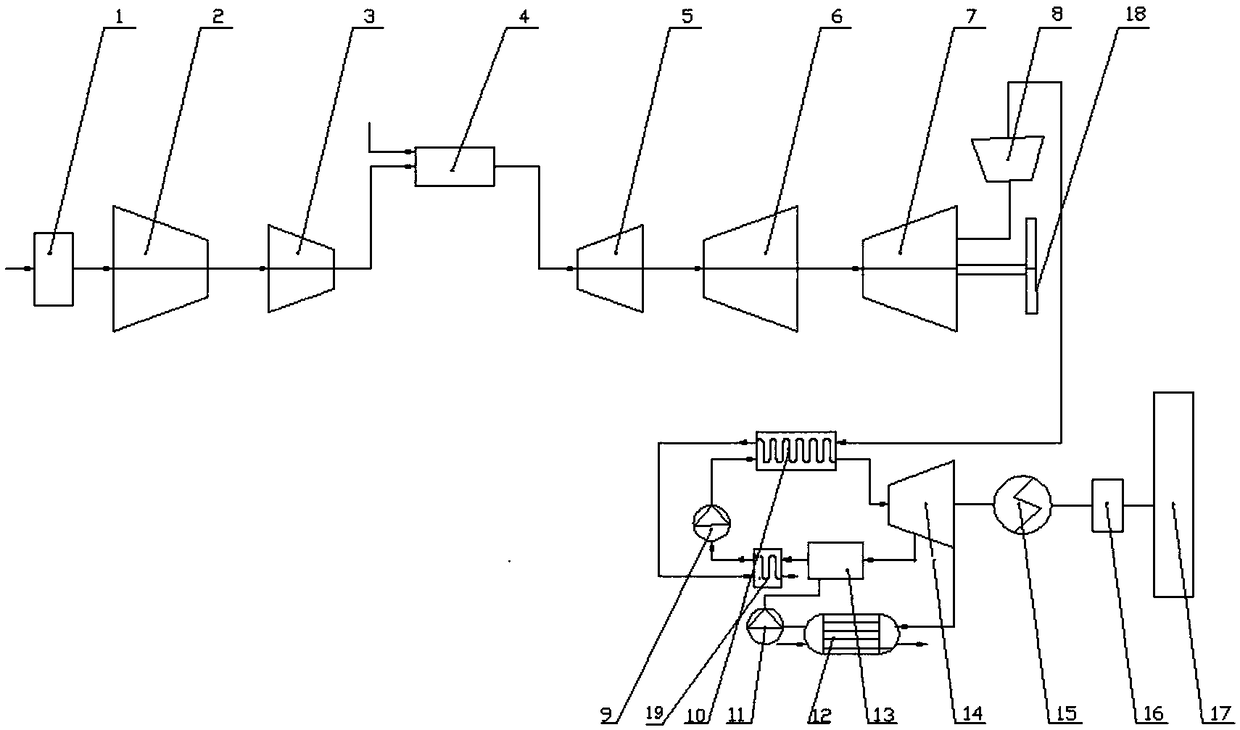

[0027] Such as figure 1 As shown, the high-efficiency waste heat recovery power generation device for gas turbines according to the present invention includes a front case 1, a low-pressure compressor 2, a high-pressure compressor 3, a combustion chamber 4, a high-pressure turbine 5, a low-pressure turbine 6, a power turbine 7, Exhaust volute 8, first working medium pump 9, first heat exchanger 10, second working medium pump 11, condenser 12, regenerator 13, turbine 14, generator 15, frequency converter 16, ship Electric system 17 , propeller 18 and second heat exchanger 19 .

[0028] The air output port of the front casing 1 is connected with the air input port of the low-pressure compressor 2, the air output port of the low-pressure compressor 2 is connected with the air input port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com