System for heating batch by utilizing secondary waste heat of float glass furnace

A float glass and heating system technology, which is applied in glass furnace equipment, glass manufacturing equipment, lighting and heating equipment, etc., can solve the problems of unstable system operation, environmental pollution, and low waste heat recovery utilization rate, and reduce production and operation Cost, stable system operation, and the effect of improving the utilization rate of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

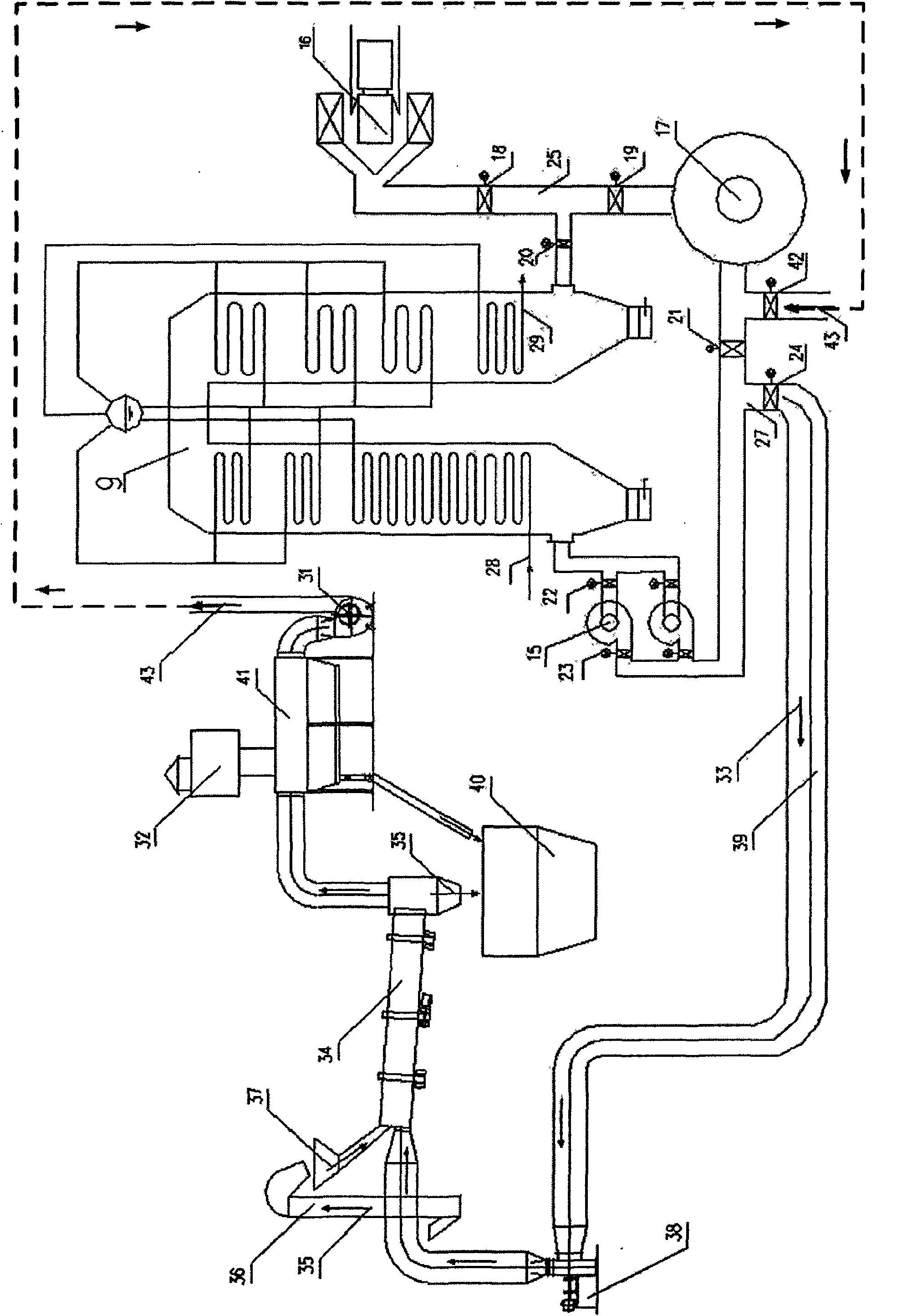

[0023] The detailed structure of the present invention, application principle, function and effect, refer to the appended figure 1 It will be described through the following embodiments.

[0024] In the secondary waste heat batch heating system of the float glass melting furnace of the present invention, the flue gas outlet of the glass melting furnace 16 is connected to the flue gas inlet of the single-drum Π-type waste heat boiler through the outlet flue 25, and the waste heat boiler The flue gas outlet is connected with a variable frequency induced draft fan 15; the variable frequency induced draft fan 15 is two variable frequency induced draft fans connected in parallel, the air inlets are equipped with induced fan inlet electric disc valves 22, and the air outlets are equipped with induced fan outlet electric disc valves 23, The outlet of the variable frequency induced draft fan 15 is connected to the inlet of the waste heat induced draft fan 38 through the bypass flue 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com