Single heat accumulating type denitration burner

A denitrification burner and single heat storage technology, which is applied in the field of industrial combustion and gas heat storage denitrification combustion, can solve the problems of increasing investment and space, increasing economic costs, and unstable combustion, etc., achieving small resistance loss, convenient operation, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

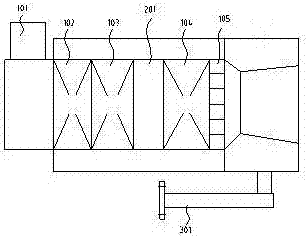

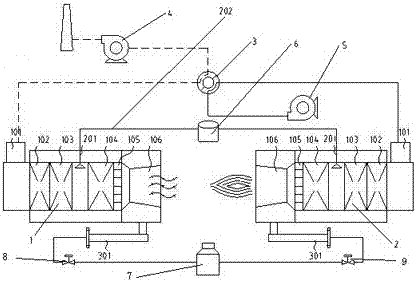

[0063] Use the single regenerative denitrification burner of the embodiment of the present invention to perform regenerative denitrification on the high-temperature flue gas generated by the burner:

[0064] Combustion process: Combustion-supporting air enters the outer low-temperature heat storage cavity 102 and the denitration honeycomb heat storage cavity 103 from the air distribution port 101 of the second single regenerative denitration burner 2, and the air continues to enter the inner layer high-temperature heat storage after being heated to about 400°C The cavity 104 is further heated to about 1000°C and enters the empty coal mixing cavity 106; the coal gas enters the empty coal mixing cavity 106 from the gas device 301, and then mixes with high-temperature preheated air for combustion, and the high-temperature flue gas formed by combustion enters the furnace.

[0065] Smoke exhaust process: After burning for a period of time, high-temperature flue gas enters the empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com