Energy saving and emission reduction comprehensive purifying treatment technology of coke oven flue gas

A technology of coke oven flue gas and coke oven flue, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as non-compliance of emissions, achieve improved environmental protection benefits, good comprehensive purification effects, and reduce The effect of dealing with the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

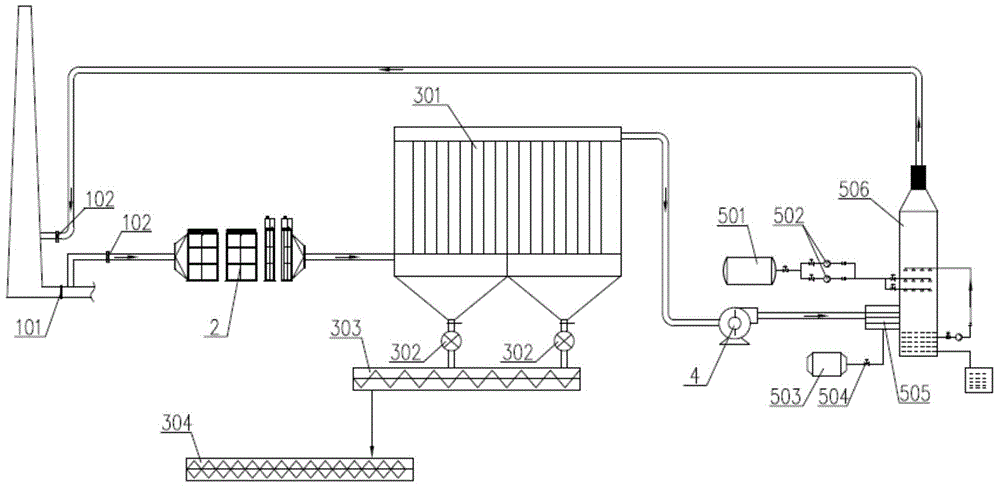

[0025] figure 1 Be the concrete implementation method of the present invention.

[0026] A coke oven flue gas energy saving and emission reduction comprehensive purification treatment process, the specific process steps and parameters are as follows:

[0027] 1) Connect the coke oven flue gas outlet regulating valve, waste heat recovery system 2, flue gas dedusting system, induced draft fan 4 and coke oven flue gas low-temperature oxidation absorption system in sequence; the coke oven flue gas outlet regulating valve includes Coke oven is divided into flue control valve 101, flue, chimney control valve 102; flue gas dust removal system includes flue gas dust removal system 301, star discharge valve 302, screw conveyor 303, screw conveyor humidifier 304; coke oven The flue gas low-temperature oxidation absorption system includes a residual ammonia water buffer tank 501, an ammonia water supply pump 502, an oxidant intensifier 503, an oxidant solenoid valve 504, a homogeneous m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com