System for desalting vacuum membrane distilled seawater by utilizing solar energy and after heat of diesel engine cylinder sleeve cooling water via cascade coupling

A cylinder liner cooling water and vacuum membrane distillation technology, which is applied in seawater treatment, energy waste water treatment, water/sewage treatment and other directions, can solve the problems of latent heat of vaporization and reduce the utilization rate of heat energy, and achieves reduction of heat loss, strong adjustment ability, The effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

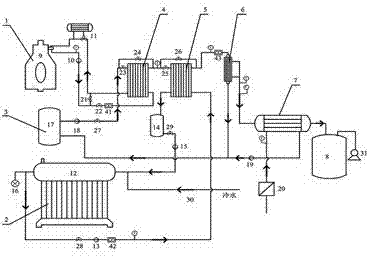

[0021] like figure 1 As shown, the present invention is a vacuum membrane distillation seawater desalination system that uses solar energy and diesel engine cylinder liner cooling water waste heat in cascade coupling, and it includes a diesel engine cylinder liner cooling water circulation system 1, a solar hot water circulation system 2, a feed liquid circulation system 3, a Heater One 4, Heat Exchanger Two 5, Membrane Module 6, Condenser and 7 Fresh Water Collection Tank 8, and related pumps, flow meters, thermometers, pressure gauges, etc.

[0022] Described heat exchanger one 4 is connected with diesel engine liner cooling water circulation system 1 and feed liquid circulation system 3 respectively; Described heat exchanger two 5 is connected with solar hot water circulation system 2 and feed liquid circulation system 3 respectively; The feed-liquid circulation system 3 is connected successively with the seawater inlet and outlet of the membrane module 6 through the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com