Self-provided power station boiler and cement kiln waste heat recovery coupling system

A waste heat recovery system and waste heat recovery technology, applied in the direction of furnaces, waste heat treatment, furnace components, etc., can solve the problems of low overall efficiency of waste heat power generation, low utilization rate of waste heat recovery, large power consumption, etc., and reduce the investment and construction of power transmission equipment , Improve operating efficiency and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

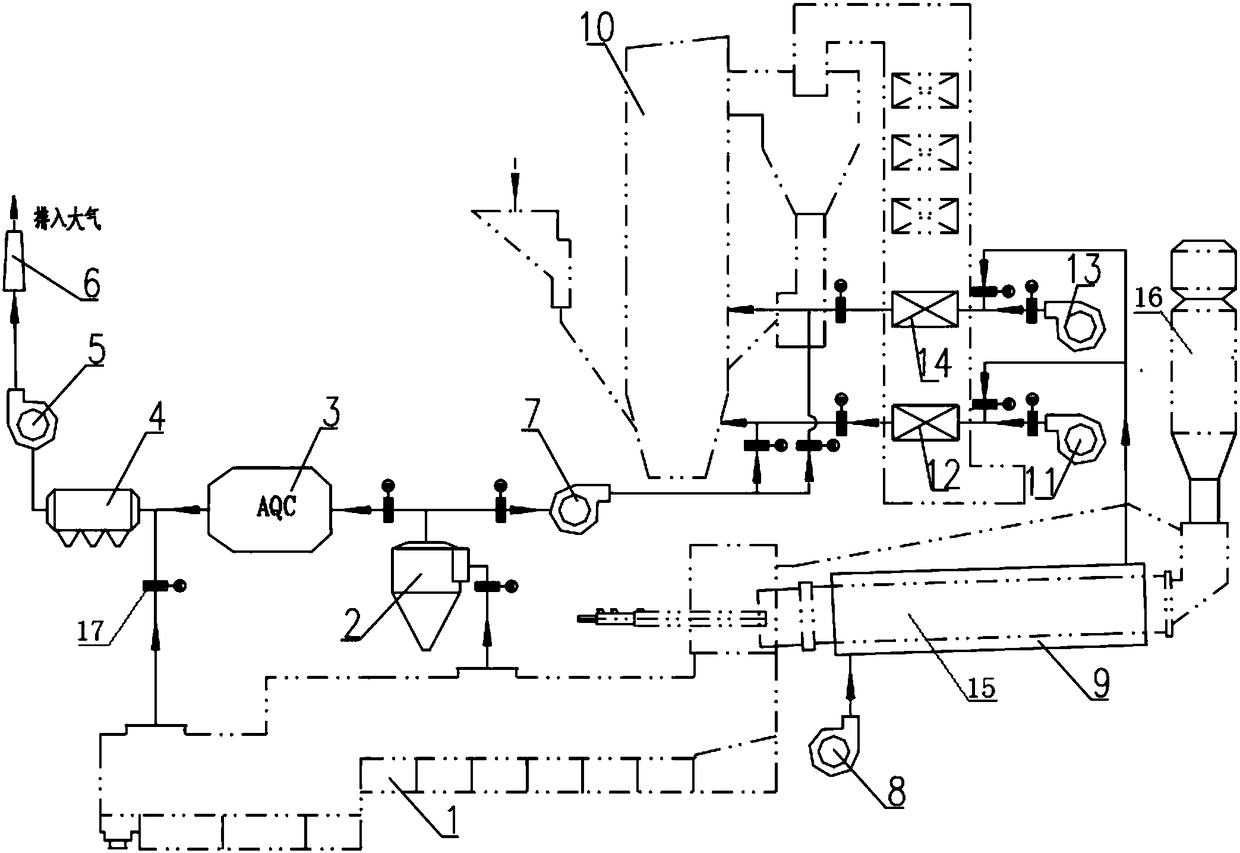

[0034] refer to figure 1 As shown, the self-provided power station circulating fluidized bed boiler and cement kiln waste heat recovery coupling system consists of kiln head waste heat recovery system, rotary kiln waste heat recovery system, and boiler system. The kiln head waste heat recovery system includes grate cooler 1 and dust collector 2 (first dedusting device), AQC boiler 3 (waste heat boiler), dust collector 4 (second dedusting device), induced draft fan 5 (induced air device), chimney 6, booster fan 7 (pressurized air device) and connecting pipes , the rotary kiln waste heat recovery system includes a blower 8 (air supply device), an air heating device 9 and connecting pipes, and the boiler system includes a circulating fluidized bed boiler 10, a primary fan 11, a primary air preheater 12, a secondary fan 13, Secondary air air preheater 14 and connecting pipes.

[0035] In the waste heat recovery system of the kiln head, air outlets are set in the middle and tail o...

Embodiment 2

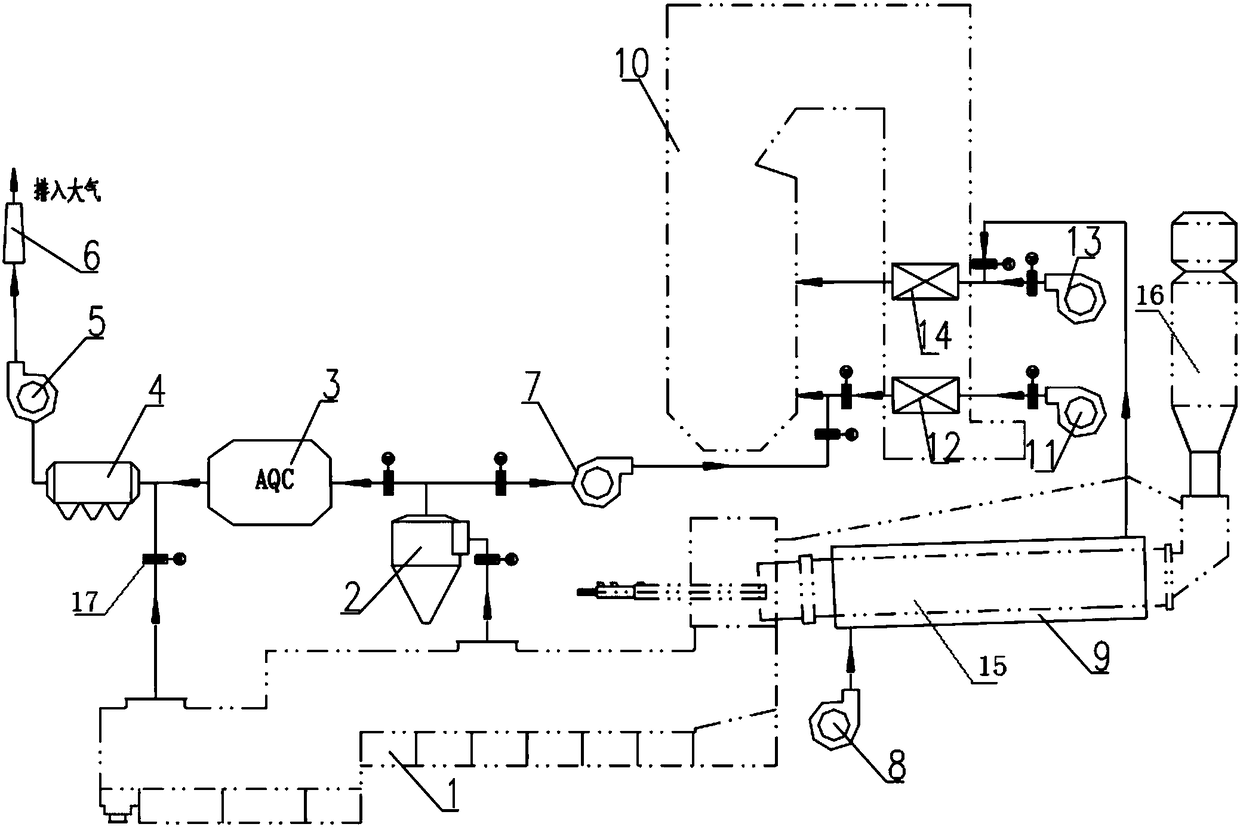

[0040] refer to figure 2 As shown, the self-provided power plant pulverized coal boiler and cement kiln waste heat recovery coupling system consists of kiln head waste heat recovery system, rotary kiln waste heat recovery system, and boiler system. The kiln head waste heat recovery system includes grate cooler 1, dust collector 2, AQC Boiler 3, dust collector 4, induced draft fan 5, chimney 6, booster fan 7 and connecting pipes, rotary kiln waste heat recovery system includes blower 8, air heating device 9 and connecting pipes, boiler system includes pulverized coal boiler 10, primary fan 11 , primary wind air preheater 12, secondary fan 13, secondary air air preheater 14 and connecting pipes.

[0041] In the waste heat recovery system of the kiln head, air outlets are set in the middle and tail of the grate cooler 1, and the hot air with a higher temperature extracted from the air outlet in the middle passes through the dust collector 2, and then passes through the AQC boile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com