After heat power station heat system for performing vacuum deoxidization using steam turbine condenser

A technology of thermal system and condenser, applied in the field of thermal system of vacuum deoxygenation waste heat power station

Inactive Publication Date: 2008-10-01

CITIC HEAVY INDUSTRIES CO LTD +1

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Water needs to be added to the waste heat power generation steam water system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

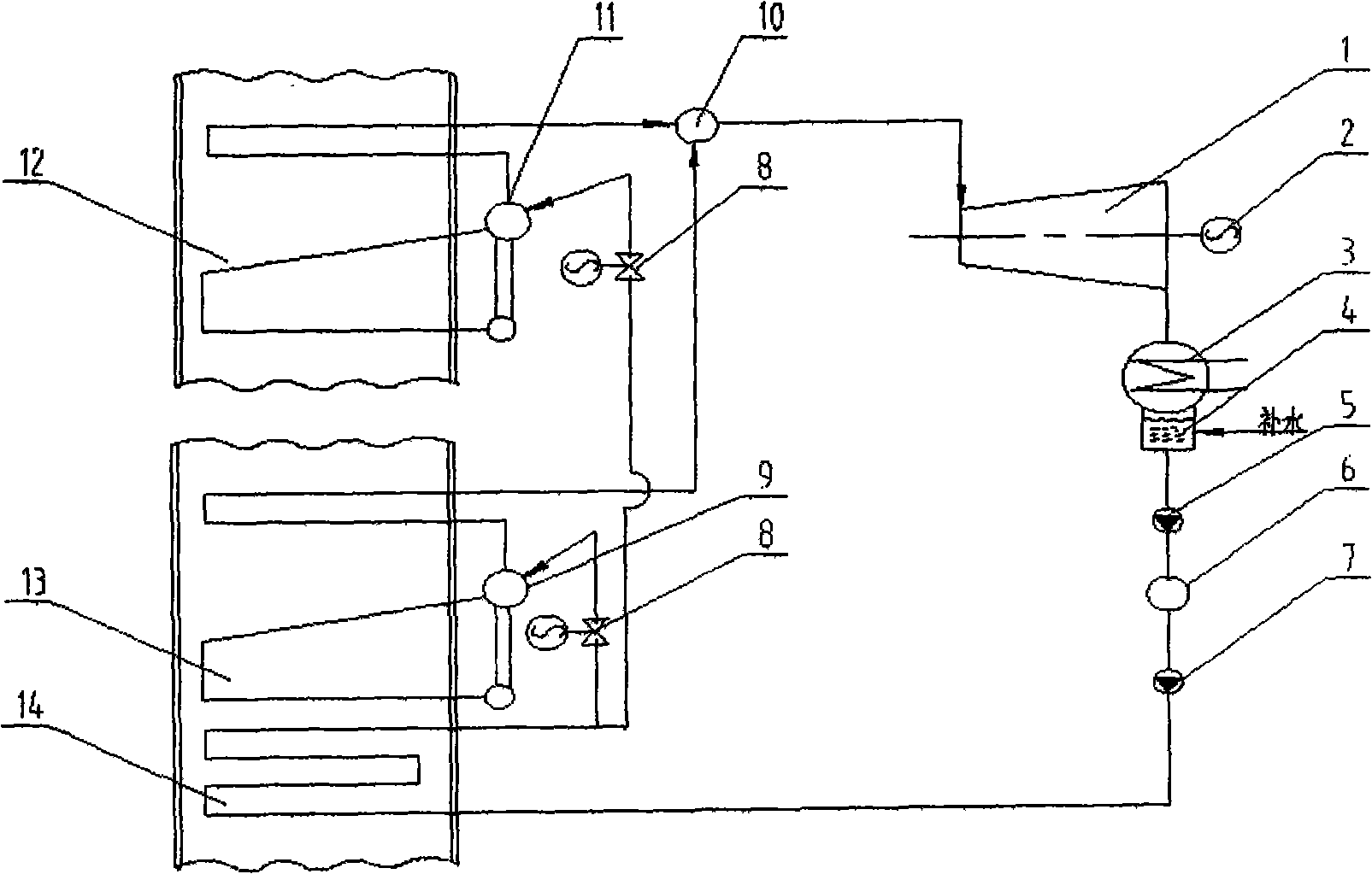

[0021] Utilize steam-admission condensing steam turbine to connect (2) generator and (3) condenser through pipes, (4) hot water well and (5) condensate pump, (6) water tank, (7) feed water pump, (8) The feed water regulating valve is connected with (9) AQC waste heat boiler drum, (10) steam collecting cylinder, (11) SP waste heat boiler drum and (12) SP waste heat boiler, (13) AQC waste heat boiler, (14) and coal-saving device connection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A waste heat power station thermodynamic system processing the vacuum deoxygenation with a steam turbine condensator is a vacuum deoxygenatiom system using the chemical deionization water inside a condensator (2) connected with a stream filling and condensing steam turbine (1) for entering an AQC waste heat boiler (13) and a SP waste heat boiler (12) for water supply, which can markedly raise the waste heat utilance. The condensed water of 41-36 degrees can enter the water heating zone of the water heat boiler, heat the condensed water higher than 170 degrees, and reduce the discharging temperature of the waste gas to 100 degrees or so, which reasonably increases the recovery waste heat utilance.

Description

Technical field: [0001] The invention relates to a thermodynamic system of a vacuum deoxygenation waste heat power station, in particular to a thermodynamic system of a vacuum deoxygenation waste heat power station using a steam turbine condenser. Background technique: [0002] ①. The National Development and Reform Commission requires enterprises to adopt ten energy-saving measures. Article 3 stipulates that "the waste heat and pressure generated in the production process should be recycled and rationally utilized." For example, iron and steel enterprises use dry coke quenching sensible heat recovery power generation, blast furnace top pressure difference power generation, blast furnace, coke oven, converter gas recovery power generation, new dry process cement production line kiln head, kiln tail exhaust gas waste heat power generation, etc. Energy conservation and environmental protection, the realization of the concept of circular economy, the corresponding guidelines an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F22D1/50F27D17/00

CPCY02P10/25

Inventor 张凯彭岩王继生曹光丘

Owner CITIC HEAVY INDUSTRIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com