Total heat recovery system for molten blast furnace slag

A technology of total heat recovery and blast furnace slag, applied in recycling technology, furnace, waste heat treatment and other directions, can solve the problems of deterioration of the environment, waste of water resources, unavailability of waste heat of blast furnace slag, etc., to improve the recycling rate and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

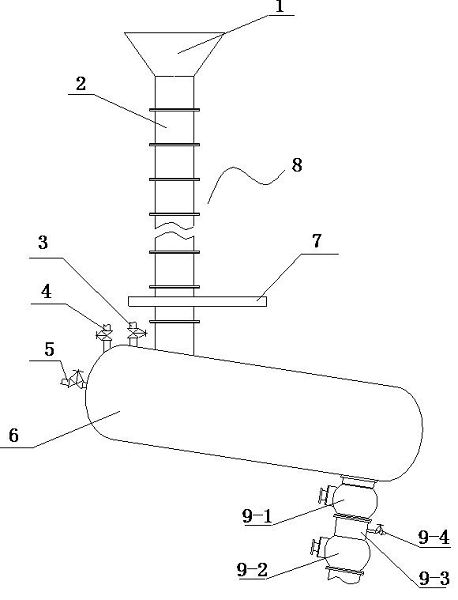

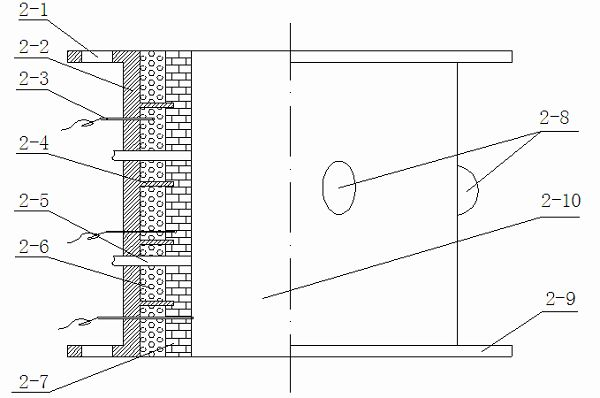

[0021] Schematic diagram of the structure of the present invention see figure 1 and figure 2 , which includes a slag feeding hopper 1 and a transportation and storage channel 8 communicated with the bottom end of the slag feeding hopper 1, the transportation and storage channel 8 is provided with heat preservation and heating devices, and the bottom end communicates with the sealed high-pressure steam tank 6; The upper part of the high-pressure steam tank 6 is provided with a water injection port 5 and a steam outlet 3, and the lower part is provided with a slagging device.

[0022] The high-pressure steam tank 6 is fixed laterally inclined, on the one hand to prevent all generated blast furnace slag particles from being blocked at the slag outlet, and on the other hand to be inclined and fixed so that the blast furnace slag particles can slide slowly to the slag outlet with the action of gravity.

[0023] The upper part of the high-pressure steam tank 6 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com