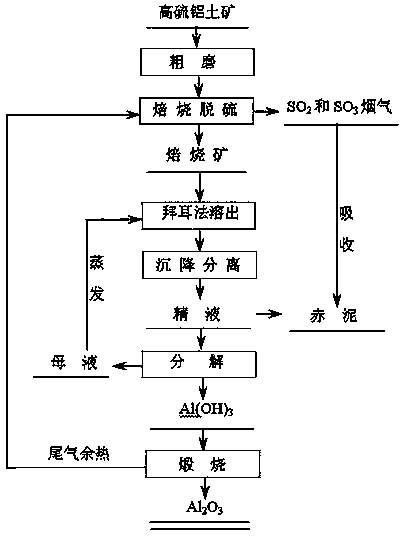

Method for producing alumina by use of high sulfur bauxite

A high-sulfur bauxite and alumina technology, applied in the direction of alumina/hydroxide, etc., to achieve good effect, high dissolution rate, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Change the composition to Al 2 o 3 64.28%, S T 1.415%, high-sulfur bauxite with A / S of 7.38 is coarsely ground to 20 mesh, accounting for 70%, take 50g and place it in a muffler furnace for desulfurization and roasting with 200ml / min of compressed air, roasting temperature 700°C, roasting time After 20 minutes, the sulfur content of the ore decreased to 0.47% after roasting, the desulfurization rate was 66.8%, and the particle size of the ore after roasting was 20 mesh, accounting for 80%.

[0027] The roasted ore was directly dissolved by the Bayer method. Under the dissolution conditions of temperature 260°C, time 60 minutes, caustic concentration 245g / L, and lime addition 6%, the relative dissolution rate of alumina reached 94.2%. The dissolution rate of 18.1%.

[0028] The roasted ore is ball milled to 200 mesh, accounting for 70% to 80%, and Bayer dissolution is carried out under the above conditions. The relative dissolution rate of alumina is 90.3%, and the di...

Embodiment 2

[0030] Change the composition to Al 2 o 3 65.08%, S T 2.329%, high-sulfur bauxite with A / S of 7.49 is coarsely ground to 20 mesh, accounting for 70%, take 50g and place it in a muffler furnace for desulfurization and roasting with 200ml / min of compressed air, the roasting temperature is 700°C, and the roasting time is After 20 minutes, the sulfur content of the ore decreased to 0.31% after roasting, the desulfurization rate was 95.7%, and the particle size of the ore after roasting was 20 mesh, accounting for 83%.

[0031] The roasted ore was directly dissolved by the Bayer method. Under the dissolution conditions of temperature 260°C, time 60 minutes, caustic concentration 245g / L, and lime addition 6%, the relative dissolution rate of alumina reached 95.1%. The dissolution rate of 14.3%.

[0032] The roasted ore is ball milled to 200 mesh, accounting for 70% to 80%, and the Bayer dissolution is carried out under the above conditions. The relative dissolution rate of alumin...

Embodiment 3

[0034] Change the composition to Al 2 o 3 66.5%, S T 2.331%, high-sulfur bauxite with A / S of 6.88 is coarsely ground to 20 mesh, accounting for 70%, take 50g and place it in a muffler furnace for roasting and desulfurization, feed 200ml / min of compressed air, roasting temperature 700°C, roasting time After 20 minutes, the sulfur content of the ore decreased to 0.48% after roasting, the desulfurization rate was 79.4%, and the particle size of the ore after roasting was 20 mesh, accounting for 81%.

[0035] The roasted ore was directly dissolved by the Bayer method. Under the conditions of dissolution at a temperature of 260°C, a time of 60 minutes, a caustic concentration of 245g / L, and a lime addition of 6%, the relative dissolution rate of alumina reached 94.8%. The dissolution rate of 16.3%.

[0036] The roasted ore is ball milled to 200 mesh, accounting for 70% to 80%, and Bayer dissolution is carried out under the above conditions. The relative dissolution rate of alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com