Device and method for recycling calcium magnesium in desulfurization waste water by using carbonization method

A technology of desulfurization wastewater and carbonization method, which is applied in the direction of chemical instruments and methods, magnesium hydroxide, calcium carbonate/strontium/barium, etc., can solve the problems of non-recyclable sludge, increased sludge volume, large consumption of chemicals, etc., and achieves increased Effects of waste water reuse rate, reduction of drainage, and mitigation of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

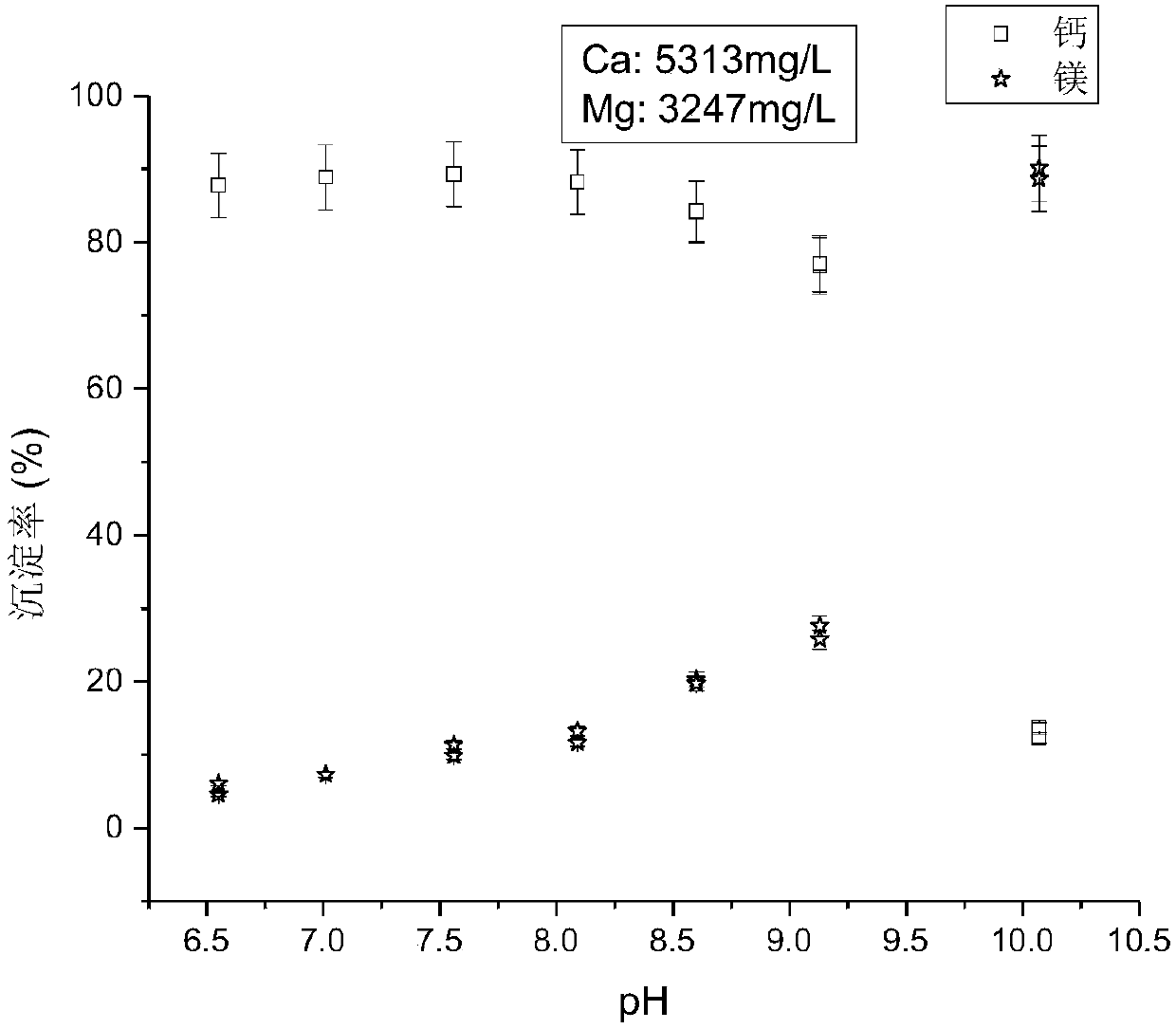

[0057] Preliminary test of carbonization method to recover calcium and magnesium in desulfurization wastewater: During the experiment, the calcium ion concentration in the simulated desulfurization wastewater was 5313mg / L, the magnesium ion concentration was 3247mg / L, the CO2 flow was controlled at 0.6L / min, and the temperature was controlled by The constant temperature magnetic stirrer is controlled at 20°C.

[0058] CO2 was continuously fed into the simulated desulfurization wastewater, and samples were taken for measurement when the pH was 9.0, 8.5, 8.0, 7.5, 7.0, and 6.0. The result is as figure 2 shown. It can be seen that when the pH is high, more Mg precipitates and less Ca precipitates. As the pH decreases, Mg precipitates gradually decrease, while Ca precipitates gradually increase, and finally stabilize at 80-90%. This is because, when the pH is high in the first stage, hydroxide precipitation is first generated, and Ca(OH) 2 Ksp is 5.5 x 10 -6 , Mg(OH) 2 The K...

Embodiment 2

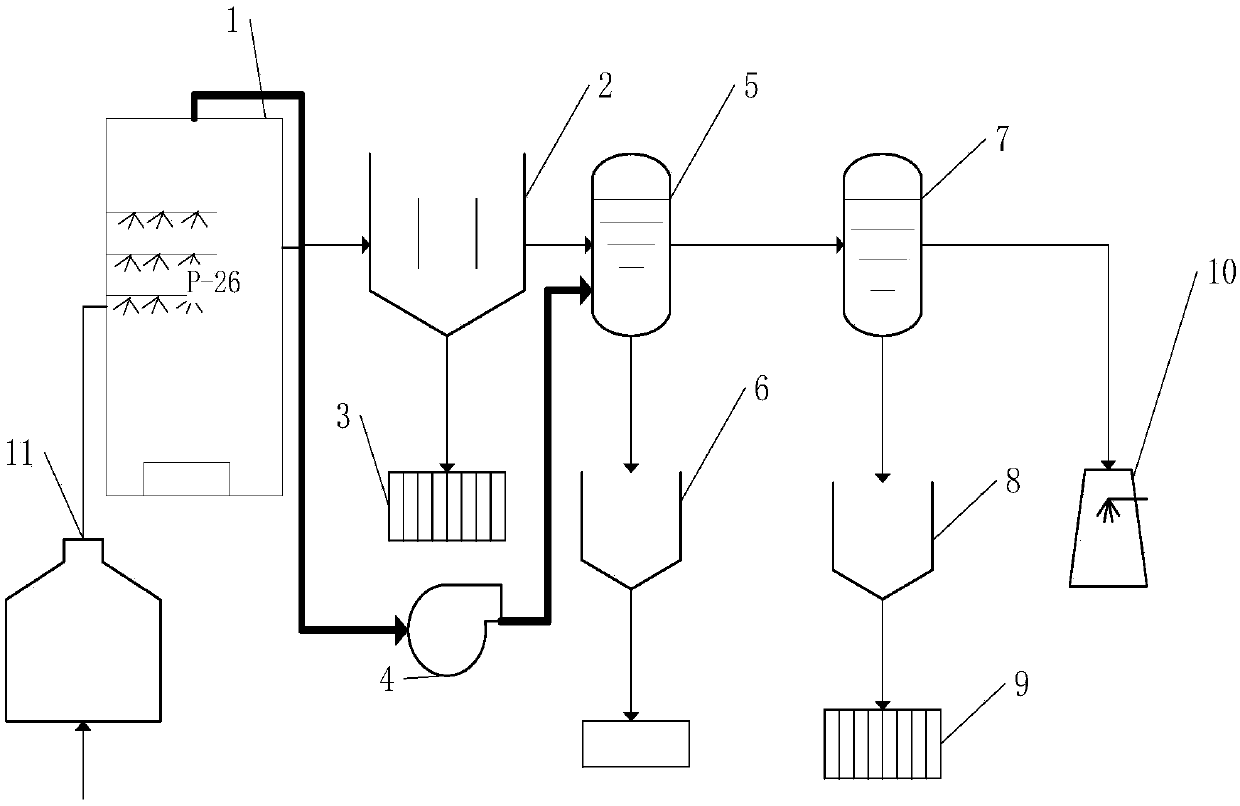

[0061] The limestone pulping system 11 sends the prepared limestone slurry into the desulfurization tower 1, and the flue gas passes into the desulfurization tower 1, and the desulfurized flue gas is introduced into the aeration tank 5 by the fan 4, and the desulfurization wastewater generated by the desulfurization tower 1 is Pass into neutralization pool 2, add Ca(OH) 2 Adjust the pH to 9 to precipitate heavy metals and other impurities in the desulfurization wastewater. The sediment in the neutralization tank 2 is sent to the plate and frame filter press 3 for pressure filtration and treated as sludge. The upper water in the neutralization tank 2 is passed into the aeration tank 5. The flue gas sent to the aeration tank by fan 4 contains 15% CO 2 , can be used to adjust the pH of the wastewater in the aeration tank, and the aeration can be stopped after the pH is adjusted to 7. At this time, most of the Ca in the wastewater 2+ CaCO 3 form precipitated. After the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com