Patents

Literature

102 results about "Calcium Phytate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium phytate used as a sequestrant is generally recognized as safe when used in accordance with good manufacturing or feeding practice. 21 CFR 582.6219 (4/1/99) from HSDB

Desulfurization agent

InactiveCN103084050AImprove desulfurization efficiencyImprove solubilityDispersed particle separationSolubilityCalcium biphosphate

The invention discloses a desulfurization agent, which comprises organic calcium carboxylates and calcium phosphate, and concretely comprises the following components, by mass, 15-20% of calcium formate, 10-16% of EDTA calcium disodium, 10-16% of calcium lactate, 0-10% of calcium phytate, 25-30% of calcium citrate, 0-10% of calcium gluconate, 10-20% of calcium oxalate, and 1-10% of calcium phosphate. According to the desulfurization agent, combination of the organic calcium carboxylates and the calcium phosphate is adopted, solubility in the solution is high, calcium ions can be ionized quickly, a desulfurization reaction speed is rapid, and desulfurization efficiency is high.

Owner:SNTO TECH GRP

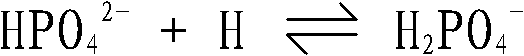

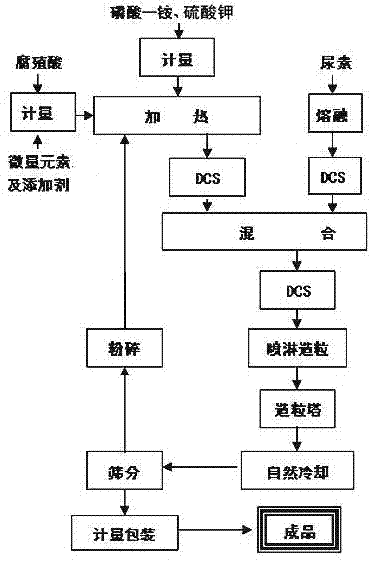

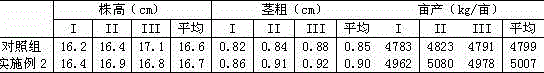

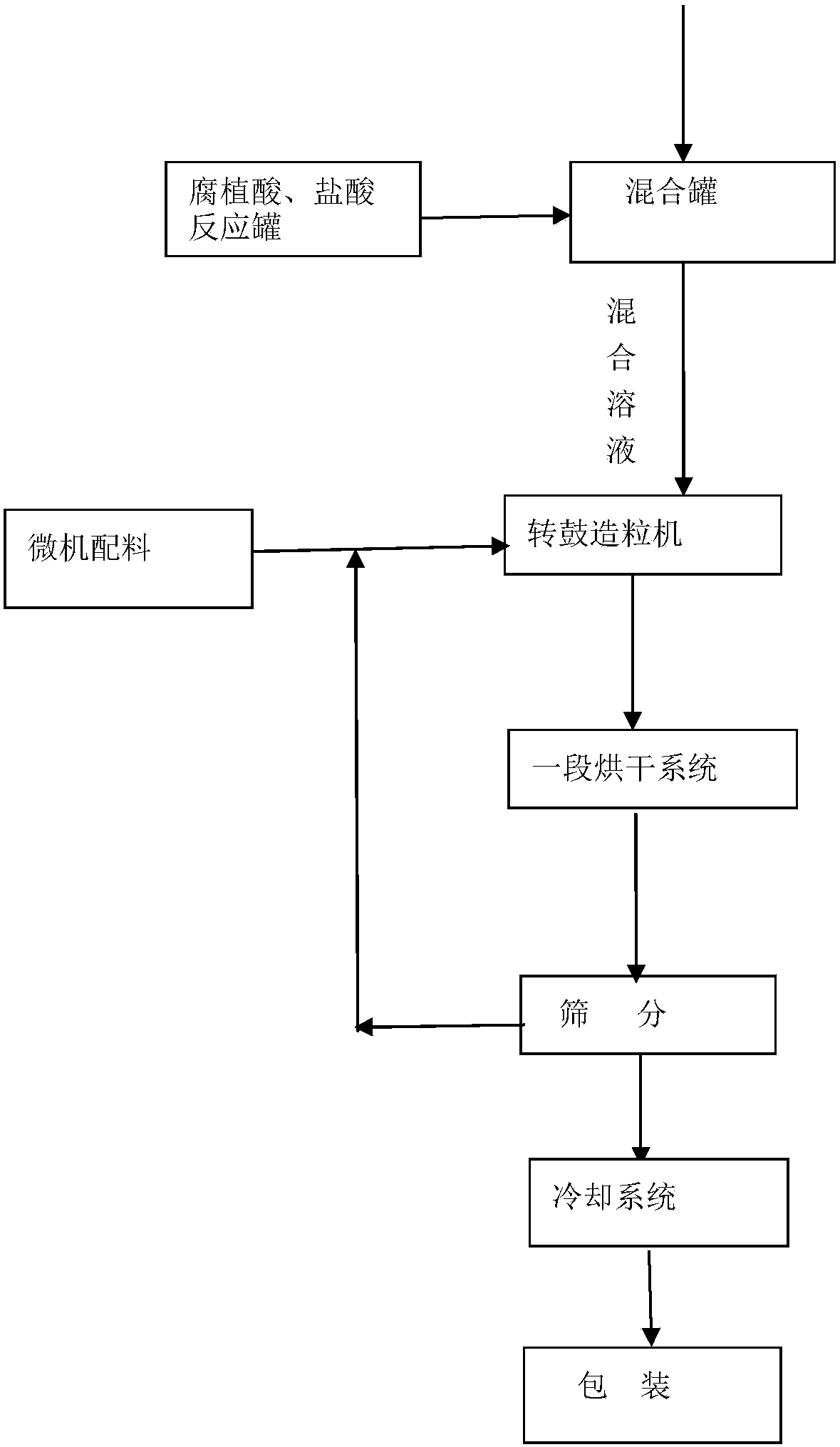

Melt granulation humic acid functional fertilizer special for corns and preparing method thereof

ActiveCN102503639AAdvanced technologyRealize continuous feedingFertiliser formsFertilizer mixturesPhosphateCaking

The invention discloses a melt granulation humic acid functional fertilizer special for corns and a preparing method thereof. The melt granulation humic acid functional fertilizer adopts raw materials of urea, monoammonium phosphate, potassium sulfate, humic acid, calcium magnesium phosphate, ethylene diamine tetra acetic acid (EDTA) chelating zinc, EDTA chelating ferrite, EDTA chelating boron, ammonium molybdate and additives, all the raw materials are dosed according to a specified ratio, and finished products are obtained through mixing, stirring, heating, filtering, granulating, cooling, sieving, anti-caking processing and measurement packaging of the raw materials. The melt granulation humic acid functional fertilizer special for corns has the advantages of being environment-friendly, balanced in nutrition, fast in fertilizer effect, high in crop absorption rate and capable of prolonging valid period of nitrogen nutrient and improving the soil, is a novel fertilizer for agricultural sustainable development and green food production, and has important meaning for promoting development of the ecological agriculture.

Owner:STANLEY AGRI GRP CO LTD

Special cotton fertilizer for regulating and controlling coastal saline-alkali land soil and preparation method thereof

ActiveCN103641666ASimple structureImprove fertilityFertilizer mixturesMagnesium phosphateAlkali soil

The invention discloses special cotton fertilizer for regulating and controlling coastal saline-alkali land soil and belongs to the technical field of special fertilizers for crops. The special cotton fertilizer is prepared from the following raw materials in parts by weight: 300-450 parts of urea, 1-100 parts of diammonium phosphate, 50-120 parts of potassium dihydrogen phosphate, 100-200 parts of potassium sulfate, 50-150 parts of calcium humate, 1-50 parts of calcium-magnesium phosphate, 1-50 parts of magnesium sulfate, 1-10 parts of zinc sulfate and 1-10 parts of high-strength water retention agent. Compared with the prior art, the special cotton fertilizer has the advantages that due to the addition of water-soluble calcium humate, the special cotton fertilizer can be used for inhibiting salt and holding moisture; due to the addition of a proper volume of water retention agent, the special cotton fertilizer can be used for regulating and controlling water retention, increasing the fertilizer effect and increasing fertilizer utilization ratio; due to the addition of essential secondary / trace elements, the resilience resistance is enhanced, and the product yield and quality are improved.

Owner:STANLEY AGRI GRP CO LTD

Process for extracting vegetable seed protein and calcium phytate from vegetable seed cake

InactiveCN1962671AEasy to separateGood repeatabilityProtein composition from vegetable seedsPeptide preparation methodsProtein solutionIsoelectric point

The invention discloses an extracting method of rape protein and phytin from rape refuse, which is characterized by the following: adopting rape refuse as raw material; immersing the protein through sodium hydroxide solution; separating; sucking to obtain residual on the bottom and protein solution; adjusting the isoelectric point of protein solution through alcaine; freezing protein sediment; drying; hyperfiltering the non-sediment protein; spraying; drying; immersing residual through alcaine; neutralizing secondarily; sediment; refining to obtain phytin.

Owner:HEFEI UNIV OF TECH

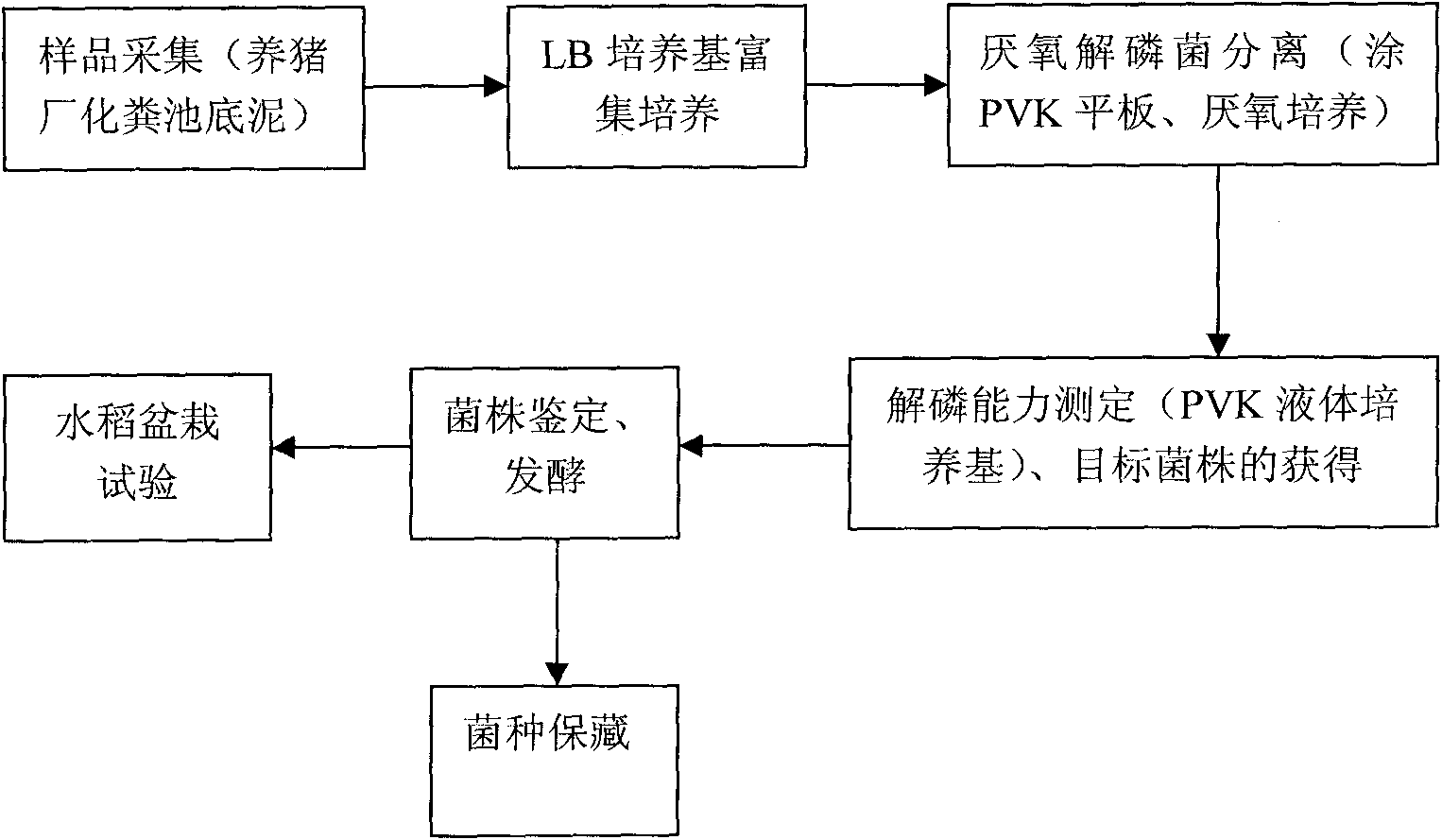

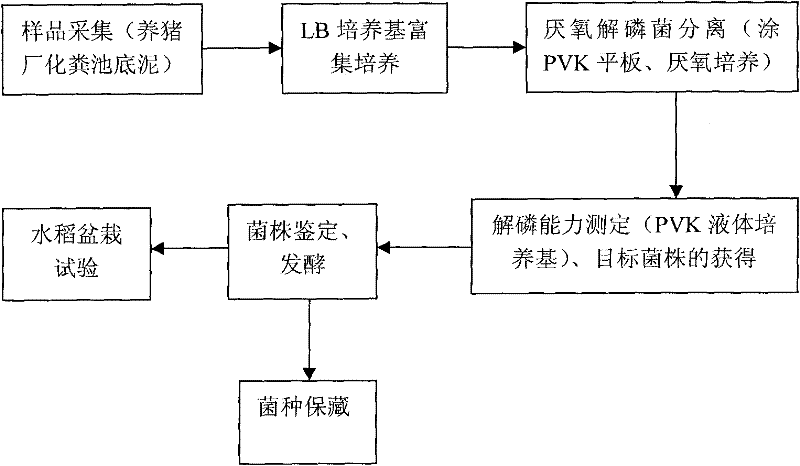

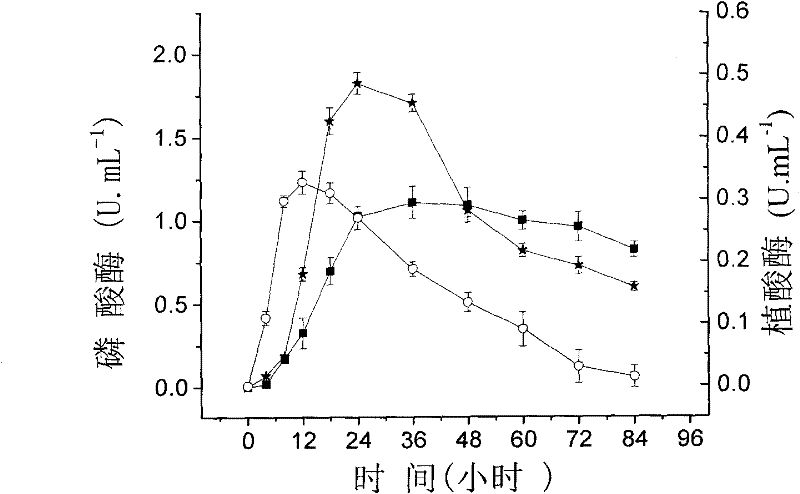

High-efficiency phosphate-solubilizing Clostridium butyricum A5-4 and applications

InactiveCN101851596AWill not cause pollutionEffective dissolutionBio-organic fraction processingBacteriaBacteroidesBiotechnology

The invention discloses high-efficiency phosphate-solubilizing Clostridium butyricum, a preparation method and application thereof, belonging to the technical field of agricultural microorganisms. In the invention, one high-efficiency phosphate-solubilizing Clostridium butyricum A5-4 strain is obtained through separation, and the strain is preserved in China Center for Type Culture Collection (CCTCC for short), wherein the preservation number is CCTCC NO: Ma010052. The bacterium is separate from the substrate sludge of a septic tank and has the capacity of efficiently dissolving calcium phosphate and calcium phytate under the anaerobic condition. The bacterium has wide nutrient requirement range, easy cultivation, low cost and storage property and can not cause environmental pollution after being reapplied to the environment. The strain can be developed into a novel microorganism agent applied to aquatic crop cultivation or aquaculture.

Owner:HUAZHONG AGRI UNIV

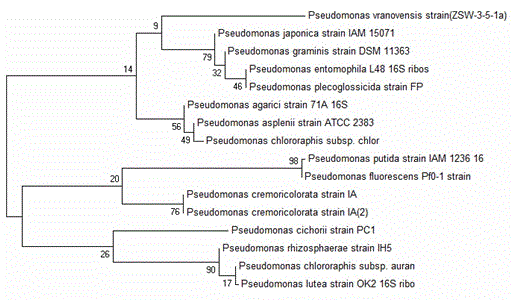

Pseudomonas vranovensis with phosphorus solubilizing capability and application thereof

InactiveCN104371946AGuaranteed stabilityStable genetic traitsBiocidePlant growth regulatorsBacterial strainMicrobiological culture

The invention discloses pseudomonas vranovensis with phosphorus solubilizing capability, a preparation method and application thereof. Through an ultraviolet-ray plasma composite mutation technology for multiple composite mutation, a bacterial strain ZSW-3-5-1a with high solubilizing efficiency on phosphorus and good stability is selected and bred, has the classification name of pseudomonas vranovensis, is preserved in China General Microbiological Culture Collection Center, and the preservation number is CGMCC No. 8750. The bacterial strain has efficient solubilizing capability on calcium phosphate and calcium phytate, and also is capable of generating a certain amount of indoleacetic acid. By using a liquid containing the bacterium or a solid inocula to inoculate corn, soybean, mustard and other crops, utilization rate on phosphorus in soil is improved and crop output is improved.

Owner:NORTHWEST UNIV

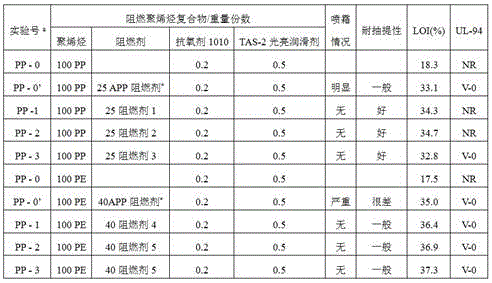

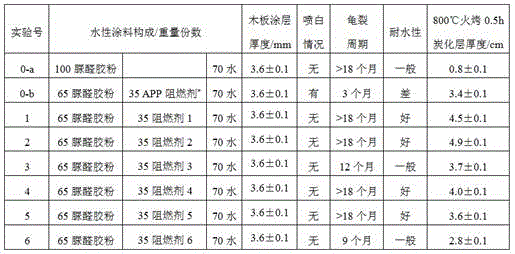

Composite flame retardant and preparation method thereof

ActiveCN106750574AEffective flame retardantGood compatibilityFireproof paintsPolyolefinAcetic anhydride

The invention discloses a composite flame retardant and a preparation method thereof. The composite flame retardant is characterized by being formed by mixing and reacting a chitin compound, a phytic acid compound, acetic anhydride, siloxane, polyamine, white carbon black, urea and water, wherein the chitin compound is at least one of chitin or chitosan; the phytic acid compound is at least one of phytic acid, sodium phytate, potassium phytate, magnesium phytate, calcium phytate, iron phytate, cobalt phytate or zinc phytate. Preparation method of the flame retardant mainly relates to a three-stage mixed reaction process: firstly, uniformly mixing the chitin compound, the phytic acid compound, water, polyamine and white carbon black; then adding acetic anhydride and siloxane to be uniformly mixed; and finally, putting urea to be uniformly mixed, and discharging, cooling and crushing the mixture to obtain a product. The composite flame retardant disclosed by the invention not only can effectively retard flames of polyolefin and woods, but also has good compatibility with polyolefin and an amino resin aqueous coating, and can effectively avoid phenomena of blooming, white spraying, dialyzing and fracturing.

Owner:FUJIAN NORMAL UNIV

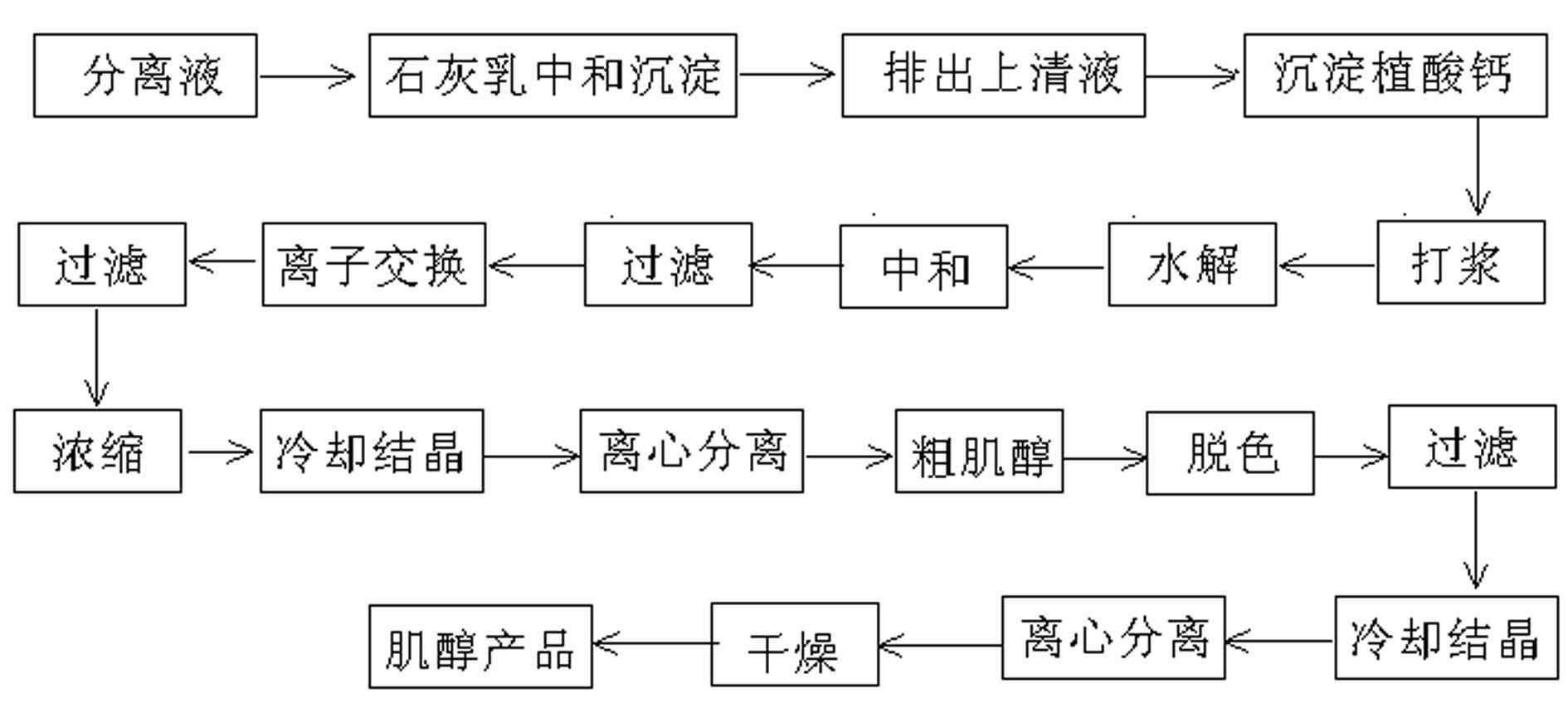

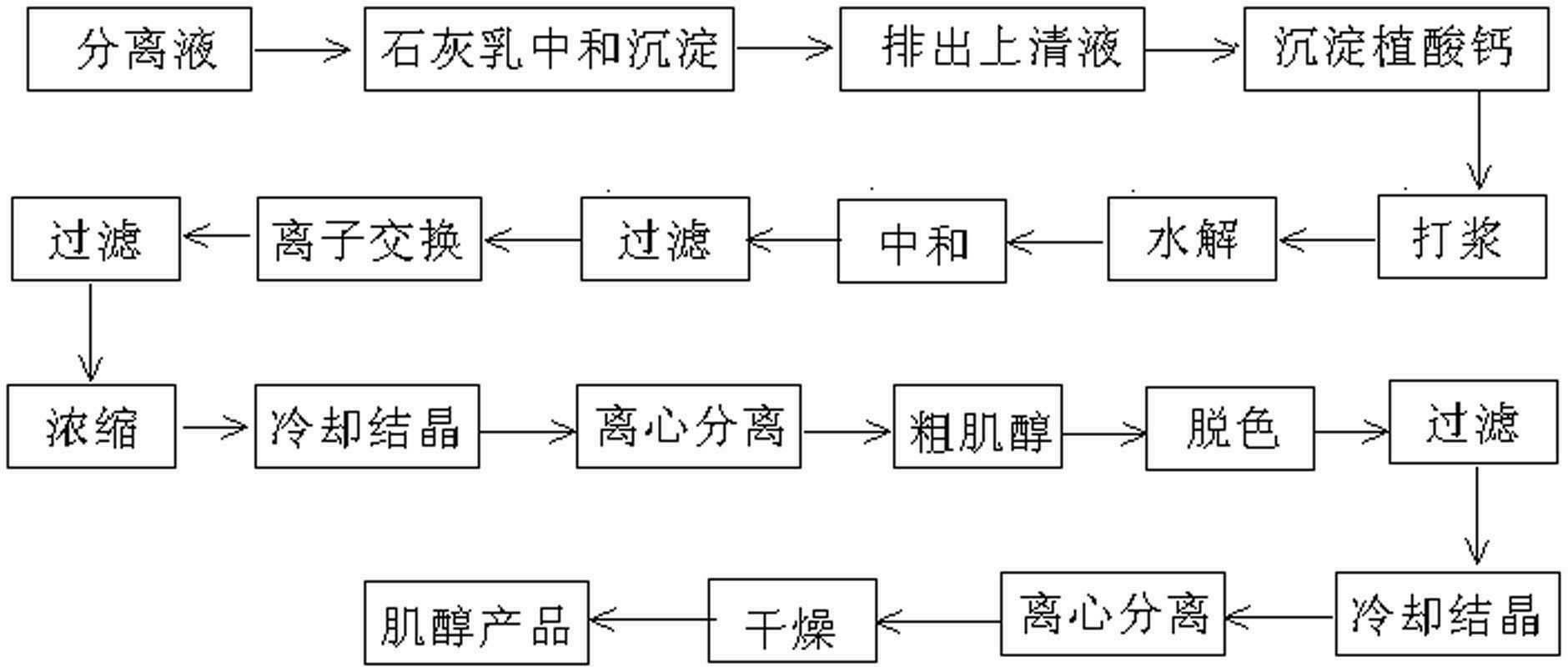

Method for preparing inositol from corn steep liquor

InactiveCN102603487AImprove concentrationHigh retention rateOrganic compound preparationHydroxy compound separation/purificationAlkaline earth metalFiltration

Owner:HENAN XINYUAN BIOTECH CO LTD

Special fertilizer for high-tower urea-formaldehyde slow-release bananas and preparation method thereof

ActiveCN103254011ANutritional balanceImprove absorption rateFertilizer mixturesEthylene diamineAgricultural engineering

The invention discloses a special fertilizer for high-tower urea-formaldehyde slow-release bananas and a preparation method thereof, relating to the technical field of agricultural fertilizers. The special fertilizer for high-tower urea-formaldehyde slow-release bananas is prepared from urea, monoammonium phosphate, potassium chloride, formaldehyde, humic acid, calcium magnesia phosphate fertilizer, EDTA (ethylene diamine tetraacetic acid) chelated boron and additives. Compared with common fertilizers, the fertilizer disclosed by the invention can obviously enhance the yield and greatly reduce the fertilizer application frequency, thereby saving the labor cost, enhancing the economic benefit and being worthy of popularization and application.

Owner:STANLEY AGRI GRP CO LTD

Comprehensive utilization method of defatted rice bran

ActiveCN103450256ATake advantage ofSituations to prevent loss of other productsGroup 5/15 element organic compoundsFermentationFiberAcid dissolution

The invention relates to a comprehensive utilization method of defatted rice bran. The method comprises the following steps of raw material pretreatment, acid extraction, first alkali precipitation, acid dissolution, second alkali precipitation, calcium phytate extraction, dextrose extraction, rice bran protein polypeptide extraction and the like. By adopting the method provided by the invention, the comprehensive utilization of the defatted rice bran is achieved, the four products with good quality, including calcium phytate, crystalline dextrose, rice bran protein polypeptide and rice bran fiber, are produced, the practical application value of the defatted rice bran is improved, and therefore the comprehensive utilization method of the defatted rice bran has a bright promotion and application prospect.

Owner:无锡新禾创工食品科技有限公司

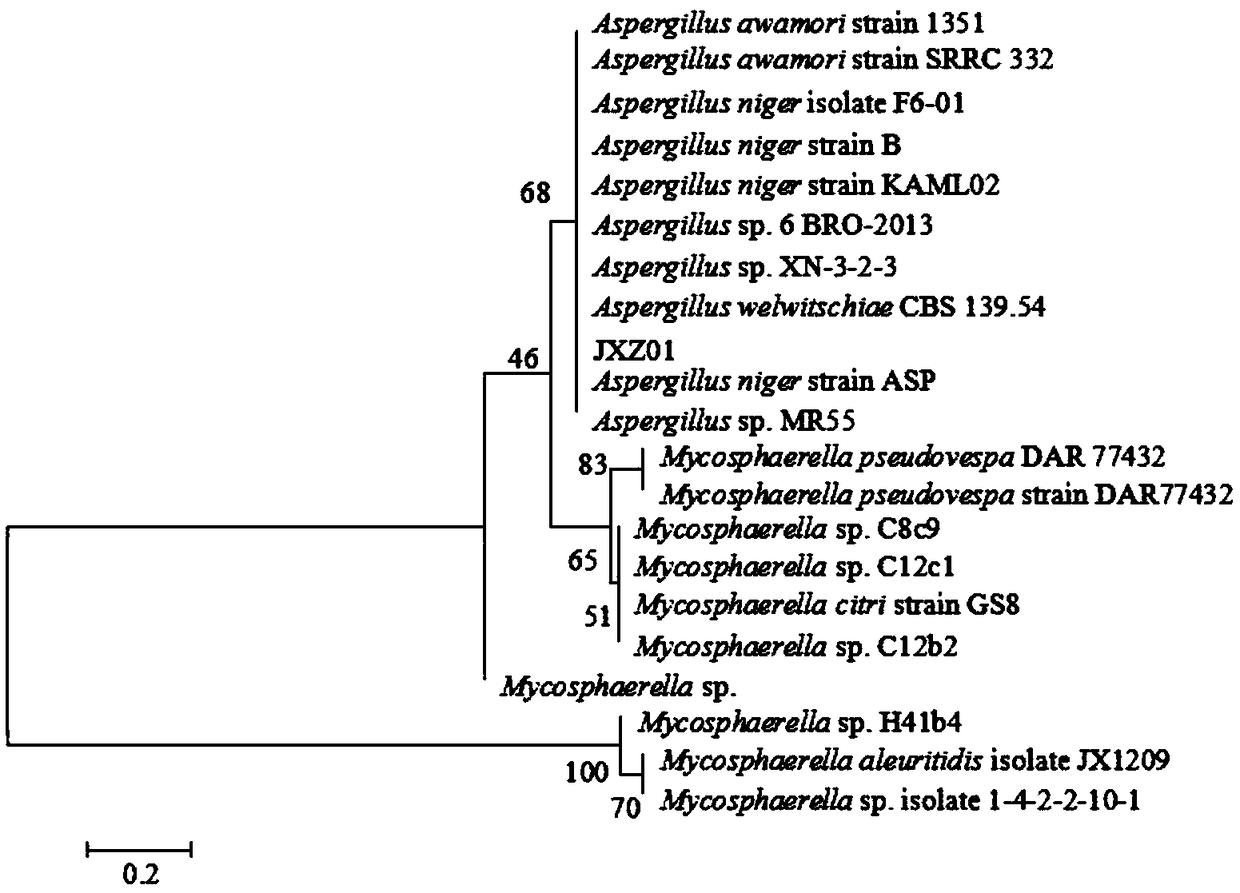

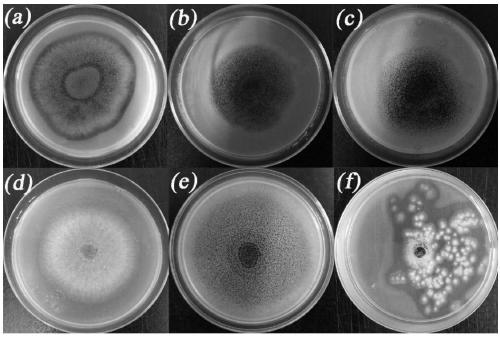

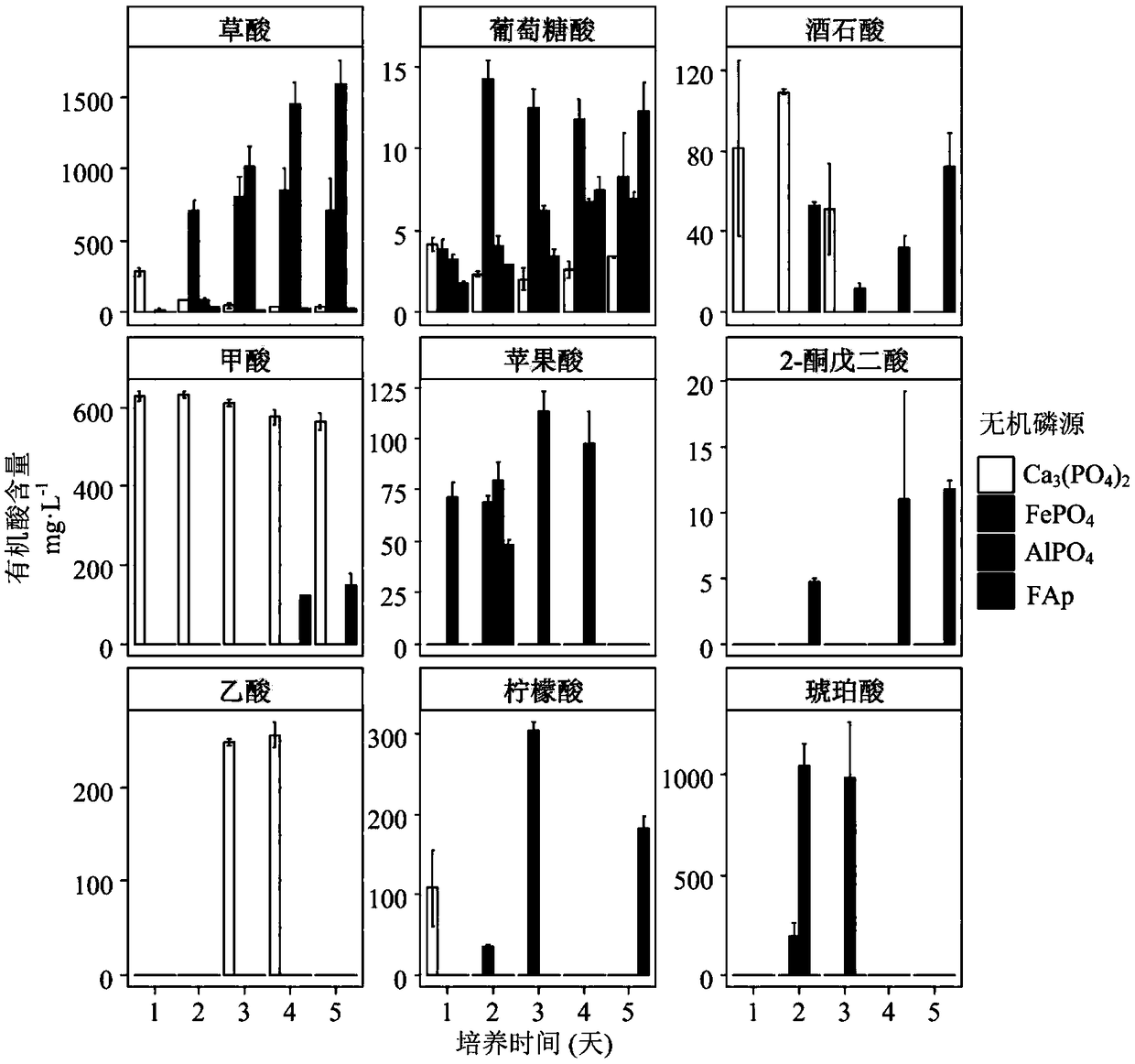

Separation and application of aspergillus niger JXZ01 with decomposition capability of various difficult-to-dissolve phosphorous sources

ActiveCN109182136AImprove toleranceImprove repair effectFungiContaminated soil reclamationPhytaseDecomposition

The invention belongs to the field of agricultural microbiology and discloses a fungus with a good phosphorous decomposition capability and application thereof to heavy metal pollution remediation. Aclassified name of the fungus is aspergillus niger with the strain number of JXZ01. The strain is preserved in China General Microbiological Culture Collection Center (CGMCC) on July 19, 2018 and thepreservation number is CGMCC_No. 15994. The strain not only can secrete various organic acids to realize the aim of decomposing tricalcium phosphate, iron phosphate, aluminum phosphate and rock phosphate and releasing soluble phosphate, also can be used for secreting acidic phosphatase and phytase to realize the effects of decomposing lecithin and calcium phytate and simultaneously releasing the soluble phosphate. The strain has good tolerance capability and repairing effect on heavy metal including Cu, Pb, Cr, Zn and the like, and has a potential of being applied to the field of the heavy metal pollution remediation of soil.

Owner:NANJING AGRICULTURAL UNIVERSITY

Composite fertilizer for cucumber and application method of composite fertilizer

InactiveCN104628442ADecomposition, hydrolysis of macromolecules is beneficial toPromote hydrolysisFertilising methodsFertilizer mixturesPhosphateCalcium

The invention discloses a composite fertilizer for cucumber. The composite fertilizer comprises the following raw materials in parts by weight: 25-30 parts of early seed manure, 30-40 parts of a medium-term flower fertilizer and 20-25 parts of later topdressing, wherein the early seed manure comprises the following raw materials in parts by weight: 30-45 parts of organic leavening, 15-18 parts of calcium superphosphate, 8-12 parts of a potash magnesium sulphate fertilizer, 2-5 parts of calcium humate, 1-3 parts of magnesium humate, 2.5-3.2 parts of sodium humate, 2-4 parts of zinc sulfate, 1-3 parts of manganese sulfate, 4-6 parts of chelated iron and 2-5 parts of boron humate; and the medium-term flower fertilizer comprises the following raw materials in parts by weight: 30-40 parts of polypeptide urea, 35-45 parts of urea-ammonium chloride, 30-35 parts of monopotassium phosphate, 20-30 parts of cassava residue, 25-28 parts of soybean cake, 15-30 parts of cottonseed cake, 8-13 parts of animal bone meal, 5-8 parts of ground phosphate rock, 5-10 parts of potassium mineral, 8-12 parts of lignite, 5-8 parts of bentonite, 9-13 parts of kaolin and 10-15 parts of montmorillonite. The invention further discloses an application method of the composite fertilizer for cucumber.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

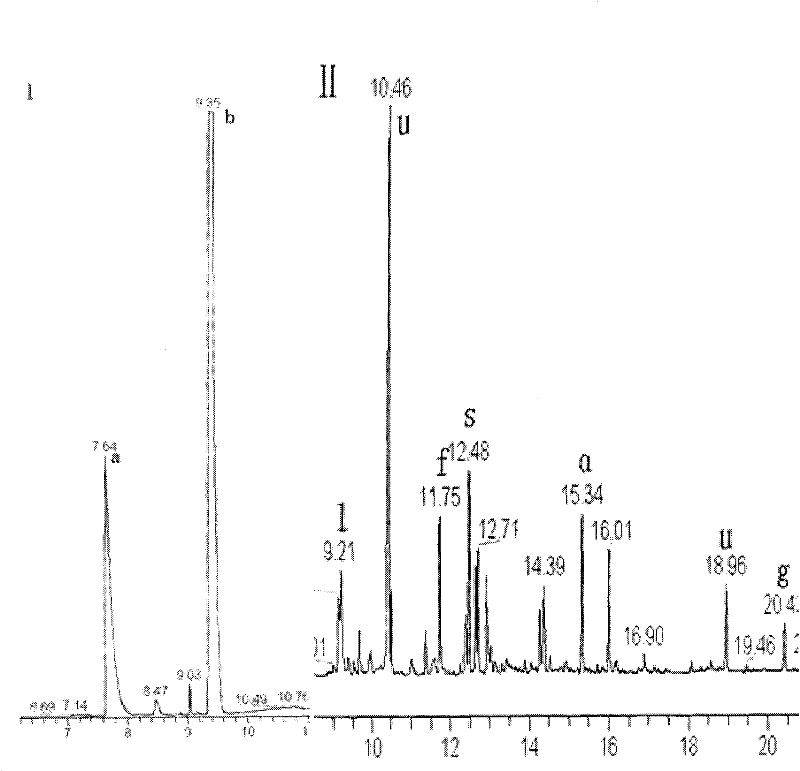

Heat-resisting phytase Pichia pastoris engineering bacterial strain and production method of heat-resisting phytase

The invention provides the construction of a Pichia pastoris engineering bacterial strain GS115 / appA NR for producing heat-resisting recombinant phytase and a method for producing the heat-resisting phytase by using the bacterial strain. A heat-resisting phytase gene is synthesized by adopting the two-step PCR method and a recombinant plasmid is constructed to be transferred into the Pichia pastoris bacterial strain GS115 through electric shock. The invention comprises the following steps of: (1) cloning the heat-resisting phytase gene synthesized by the two-step PCR method into a Pichia pastoris secretive expression vector to obtain a Pichia pastoris recombinant expression plasmid; (2) transferring the ombinant expression plasmid to the Pichia pastoris host GS115 through electric shock, screening by using an MD flat board and a substrate flat board containing calcium phytate, and then screening out a bacterial strain with largest hydrolysis circle; and (3) choosing positive clone and inducing to express by using 0.5% methanol. The heat stability of the recombinant heat-resisting phytase expressed by the Pichia pastoris engineering bacterial strain GS115 / appA NR is much higher than that of E.coli K12 wild type phytase through measurements, and specifically, 92% of enzymatic activity can still be maintained after a water bath at 95 DEG C for 10 min. The fermentation crude enzymatic activity of the recombinant phytase produced by fermenting the Pichia pastoris engineering bacterial strain can reach 978 U / mL.

Owner:HUBEI UNIV

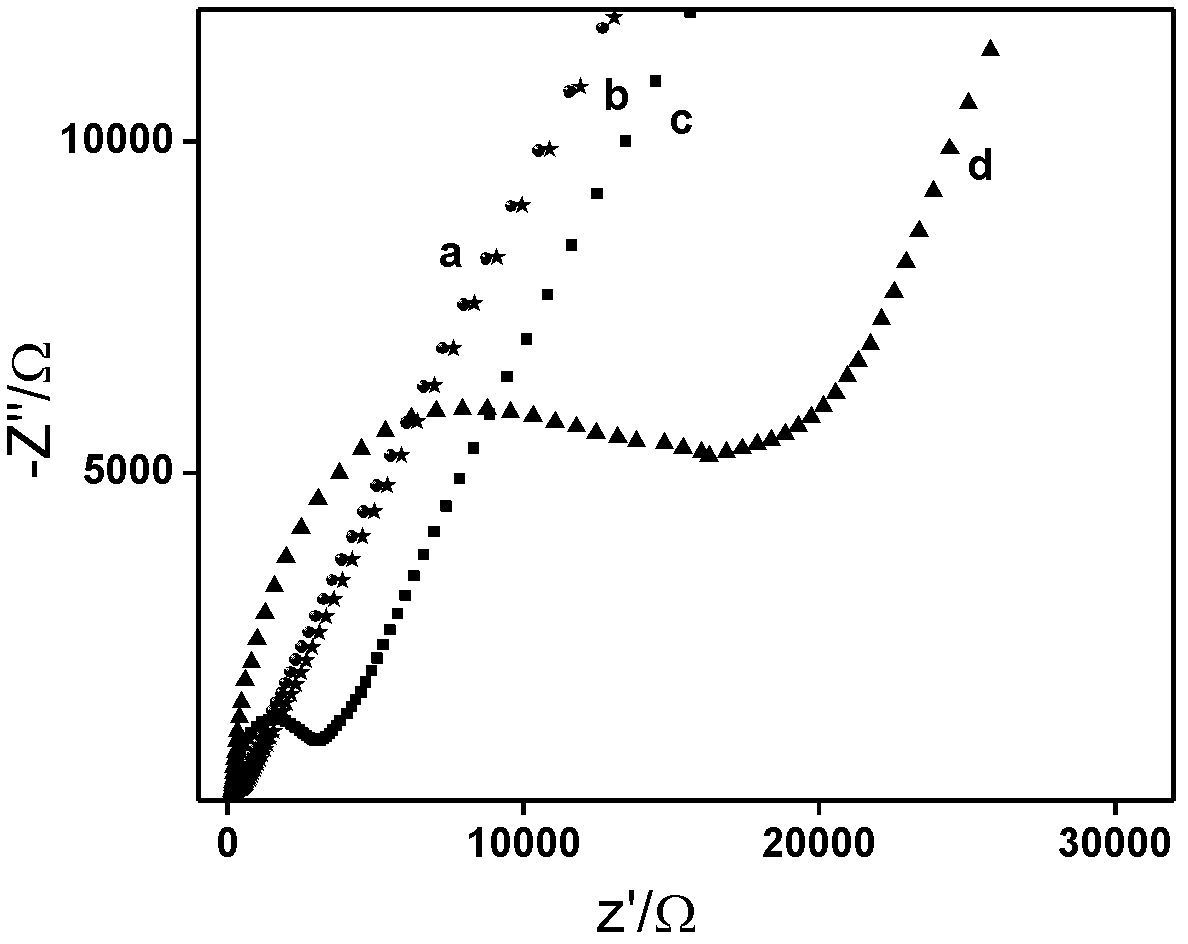

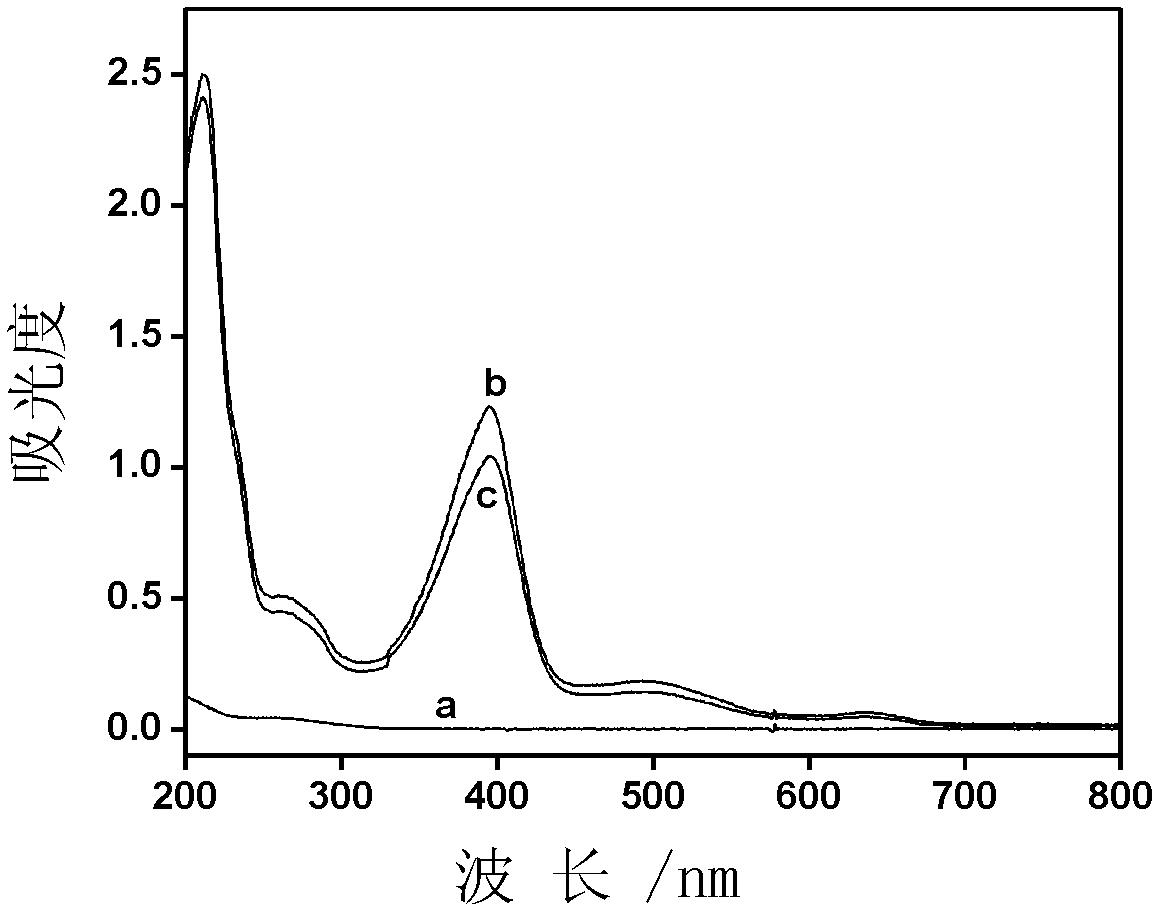

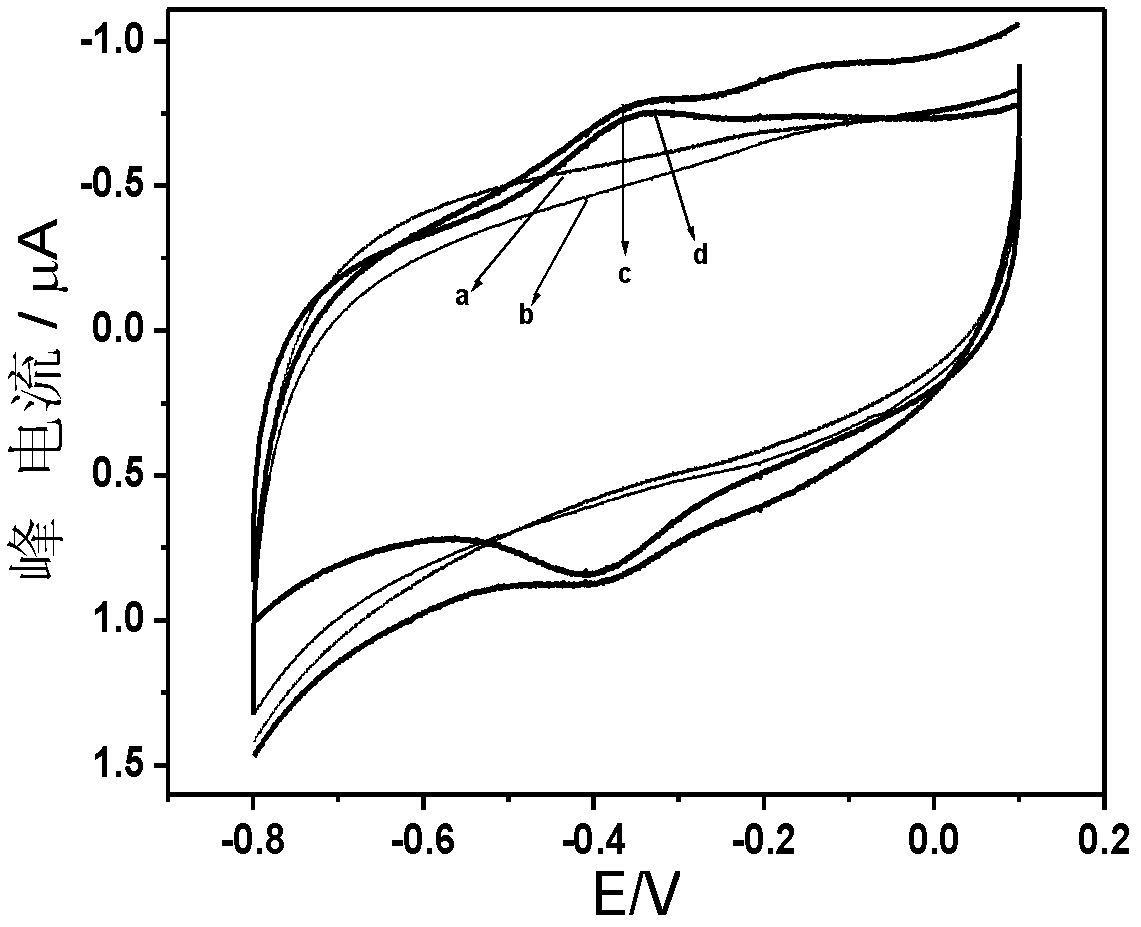

Hydrogen peroxide biosensor and preparation method thereof

InactiveCN102495116AGood biocompatibilityEasy to degradeMaterial electrochemical variablesEnvironmental resistancePhosphate

The invention discloses a hydrogen peroxide biosensor and a preparation method thereof. According to the invention, by using a self-assembly process, a Nafion / HRP / Ca-IP6 / GCE sensor is prepared by absorbing HRP onto the surface of an electrode through electrostatic interaction and chelation between phosphate ester bonds and Ca<2+>, with calcium phytate as a bridging agent; the prepared sensor has high affinity to an enzyme substrate, can realize direct electron transfer of horseradish peroxidase and has performance like a short response time to hydrogen peroxide, low detection limit and high sensitivity. Meanwhile, the preparation method provided in the invention is simple, environment-friendly and economy.

Owner:SHANGHAI NORMAL UNIVERSITY

Water-based metallic paint

The invention discloses a water-based metallic paint. The metallic paint comprises the following components in parts by weight: 50-65 parts of polyacrylamide, 20-27 parts of N-tert-butyl-2-benzothiazole sulfenamide, 20-25 parts of aluminium paste, 2-6 parts of calcium phytate, 1-5 part(s) of propanediol ether and 100 parts of water. The water-based metallic paint dispenses with the traditional additive of formaldehyde and is conducive to environment protection. Besides, the water-based metallic paint is extremely-high in flexibility, and has low probability of damage under the action of an external force.

Owner:珠海市立州水性涂料有限公司

Production method for preparing high-purity calcium phytate by utilizing membrane technology

InactiveCN103242362AReduce energy consumptionDoes not destroy biological activityGroup 5/15 element organic compoundsSeparation technologyMembrane technology

The invention relates to a production method for preparing high-purity calcium phytate by utilizing a membrane technology. The production method comprises the following concrete operating steps of: (1) smashing degreased rice bran and carrying out acid leaching; (2) filtering by utilizing a frame plate to obtain merged filtrate; (3) carrying out ultrafitration, and collecting membrane transmission fluid and trapped fluid; (4) adding saturated lime water and a sodium hydroxide solution for neutralization, and collecting two precipitated fluids; (5) carrying out microfiltration, and collecting the trapped fluid to obtain two liquid calcium phytates; and (6) drying to obtain two solid calcium phytates, wherein purity of solid calcium phytate obtained by the membrane transmission fluid is more than 82%, the purity of solid calcium phytate obtained by the trapped fluid is more than 69%, and yield calculated by degreased rice bran raw material is 12.5%. According to the production method, the traditional calcium phytate extraction process is combined with the membrane separation technology, and the characteristics of no phase change, low energy consumption, no damage on biological activity and easy operation of a membrane are utilized, so that the purity of the product is improved, a decolorization link in the original process is removed, production energy consumption is reduced, operation is easy, and industrialized production can be facilitated.

Owner:HEFEI UNIV OF TECH +1

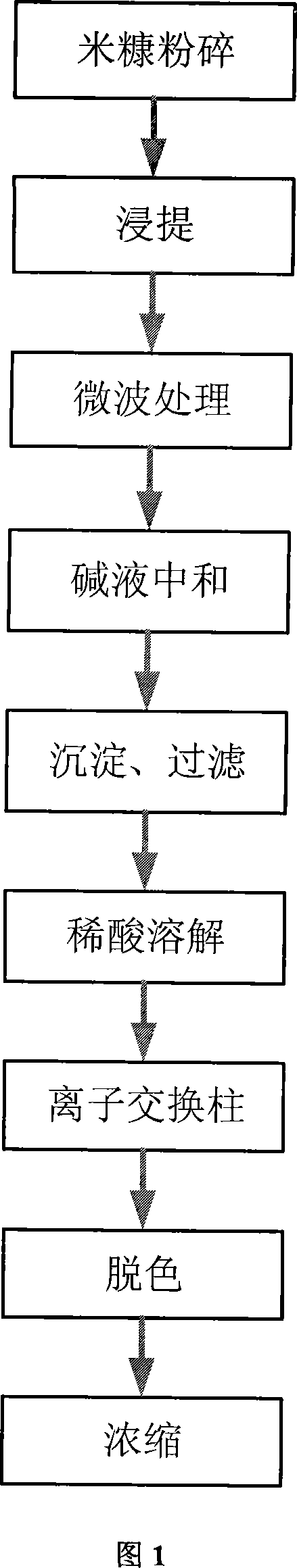

Extraction method of phytic acid in rice bran

InactiveCN101205238AReduce extraction timeHigh purityGroup 5/15 element organic compoundsCalcium hydroxideEmulsion

The invention relates to a method for extracting the phytic acid from rice bran, in particular to an extraction method for utilizing the microwave treatment technology to obtain the phytic acid from the rice bran. The method of the invention comprises the steps that: the samples are treated using the microwave with a power ranging from 500W to 1200W after the rice bran is broken and is extracted using the hydrogen chloride solution; then the pH of the obtained solution is adjusted to range from 1.0 to 3.0 using the sodium hydroxide solution and then the processed solution is driven to rest in a static state and is stirred for 0.5 to 1 hour; the beige suspension liquid is obtained through filtration and the pH of the filtrate is first adjusted to 4.0 using the 10 per cent calcium hydroxide emulsion and then the pH of the processed solution is adjusted to exceed 7.0 using the sodium hydroxide solution with a concentration of 1mol / L instead of 10 per cent calcium hydroxide emulsion so as to obtian the beige turbid liquid in which the white precipitates are contained; the beige turbid liquid is stirred uniformly before the turbid liquid rests for 1 to 2 hours so as to completely precipitate the turbid liquid; after the turbid liquid is filtered, the intermediates, calcium phytate pulps ranging from grey to drab in color, are obtained; the intermediates are converted into the existence in the form of ions through dissolution and then the phytic acids, which are the final products, are prepared through ion exchange, decoloration and concentration. Compared with the prior art, the invention has the advantages of high extraction rate, short time, high product quality, excellent color, simple and convenient operation, suitability for the industrialized production, etc.

Owner:SHANGHAI INST OF TECH

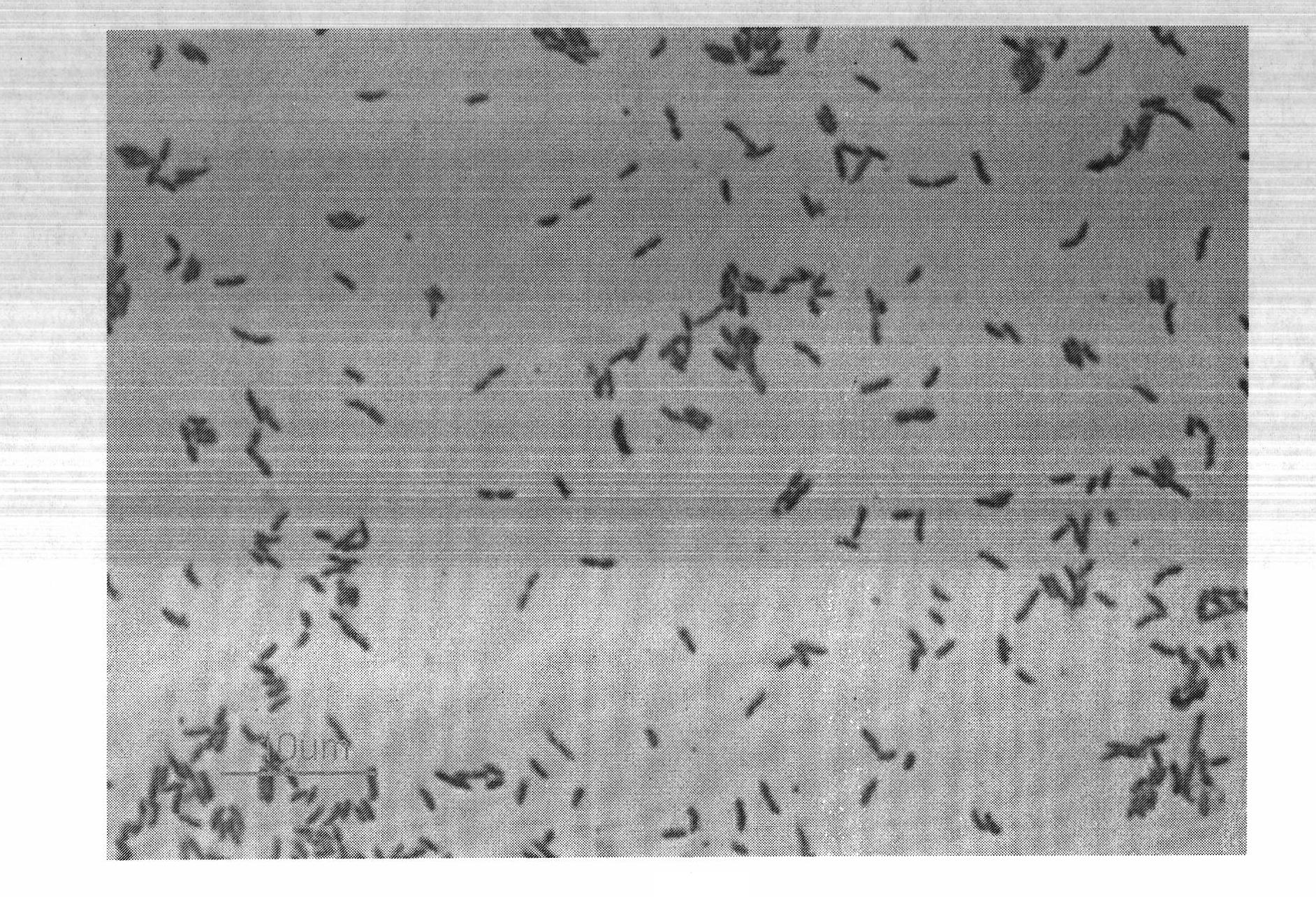

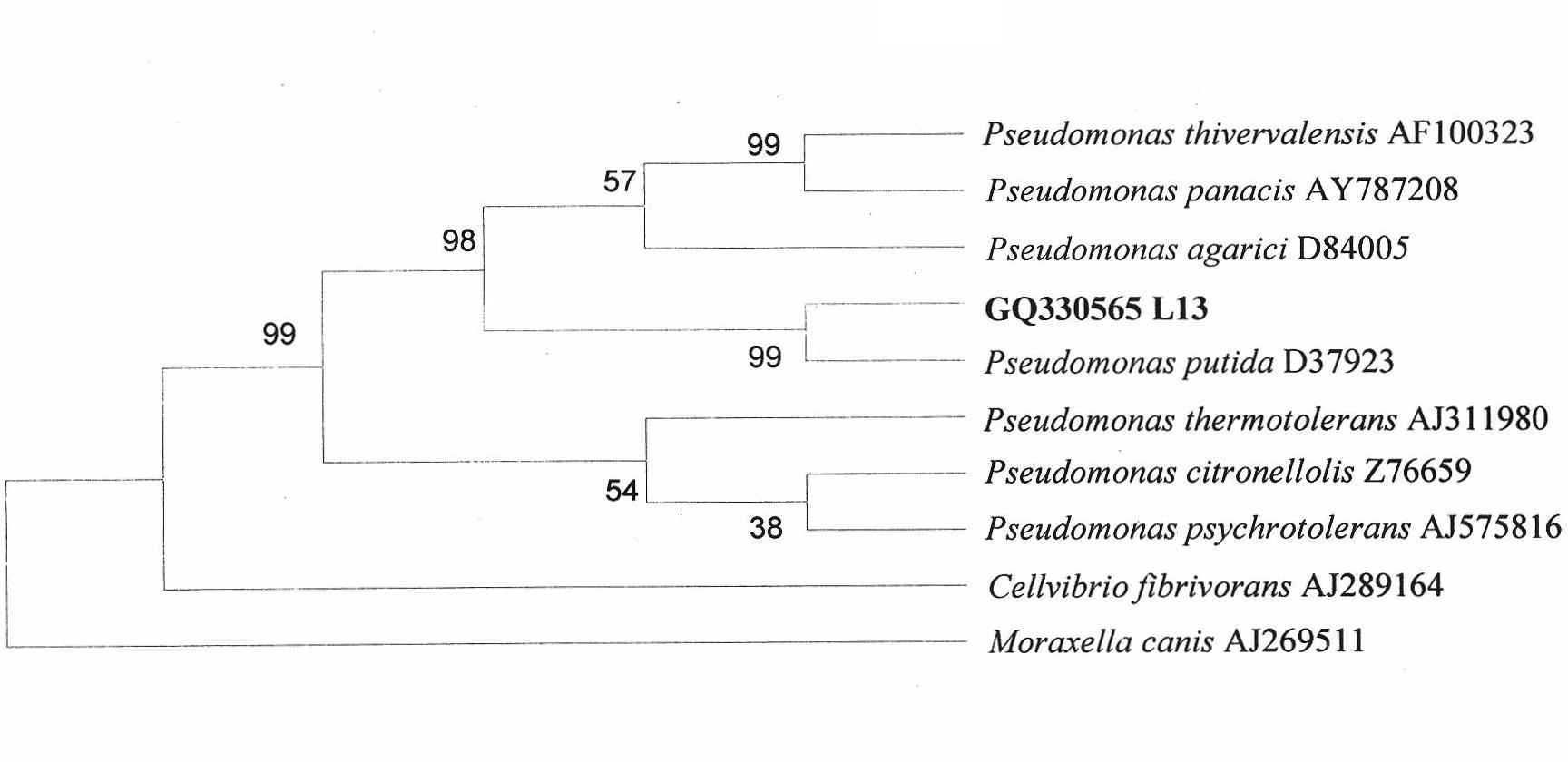

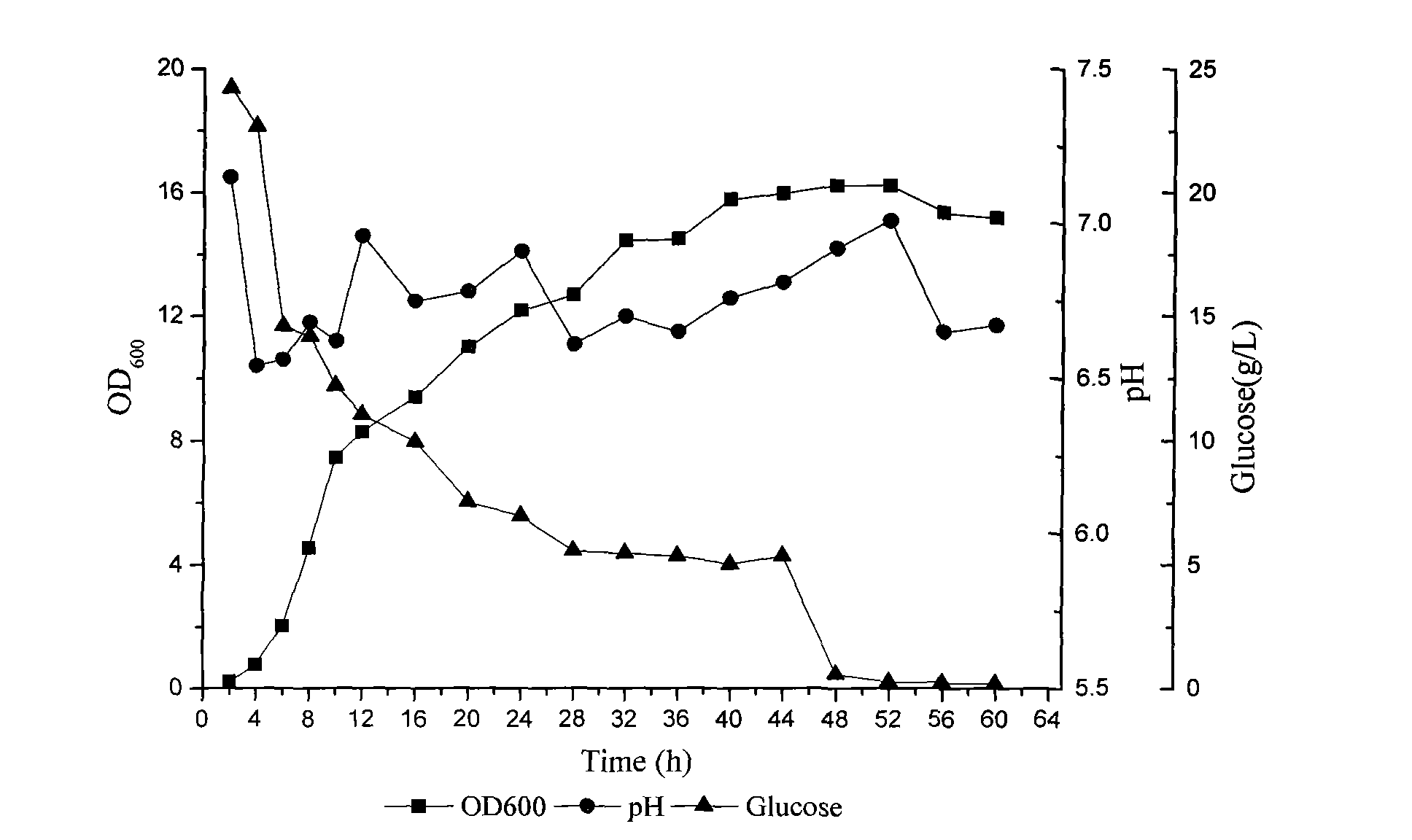

Phosphorus-dissolving pseudomonas putida L13 and fermentation process thereof

InactiveCN102649941APromote growthImprove micro-ecological environmentBacteriaMicroorganism based processesPhosphatePseudomonas putida

The invention belongs to the technical field of agricultural microbiology, and particularly relates to the separation screening and fermentation cultivation of phosphorus-dissolving pseudomonas putida L13. A phosphorus-dissolving pseudomonas putida L13 strain with the capacity of dissolving phosphorus is obtained through separation, and the preservation No. is CCTCC No.2010342. The fermentation process comprises the following steps of: (1) taking L13 bacterial strain slope seeds for streak cultivation on an LB (lysogeny broth) culture medium flat plate to obtain first-level seeds; (2) inoculating a first-level seed single bacterial colony into an LB culture medium shake flask to make OD (optical density) 600 be 2.0 to obtain second-level seeds; (3) inoculating the second-level seeds into a shake flask for fermentation cultivation to obtain the pseudomonas putida; or inoculating the second-level seeds into a fermentation tank so as to obtain the pseudomonas putida through optimized cultivation. The pseudomonas putida strain disclosed by the invention grows rapidly, the yield of the pseudomonas putida is high, and the viable count can reach more than 10 billions. The phosphorus-dissolving amount of the phosphorus-dissolving pseudomonas putida in a PKO (Pikovskaya') culture medium in which 1-3g / L of calcium phytate is the unique phosphorus source can reach 120-220mg / L, and the phosphorus-dissolving amount of the phosphorus-dissolving pseudomonas putida in a PKO culture medium in which 4-6g / L of tricalcium phosphate is the unique phosphorus source can reach 300-500mg / L.

Owner:TOBACCO RES INST OF HUBEI PROVINCE +2

Improved metallic paint

InactiveCN104164155AImprove high temperature resistanceGood scrub resistanceCoatingsLacquerTemperature resistance

Disclosed improved metallic paint is prepared from the following raw materials in parts by weight: 45-75 parts of deionized water, 5-10 parts of twelve-carbon alcohol ester, 10-15 parts of calcium phytate, 10-16 parts of meerschaum, 7-14 parts of methylamino propanol, 9-18 parts of propanediol ether, 10-15 parts of mica powder, 9-13 parts of jade powder, 13-26 parts of ethyl acetate, 5-12 parts of ascorbic acid, 25-45 parts of polyacrylamide, 5-15 parts of mineral oil silicon, 30-35 parts of N-tert-butyl-2-benzothiazolesulfenamide, 11-21 parts of aluminium-silver paste, and 8-13 parts of potassium acrylate copolymer. The provided superior improved metallic paint is effectively enhanced in high temperature resistance, enhanced in stability, wide in application scope, easy for maintaining, resistant to adhesion and resistant to scrubbing.

Owner:QINGDAO JISHUNLONG TRADING

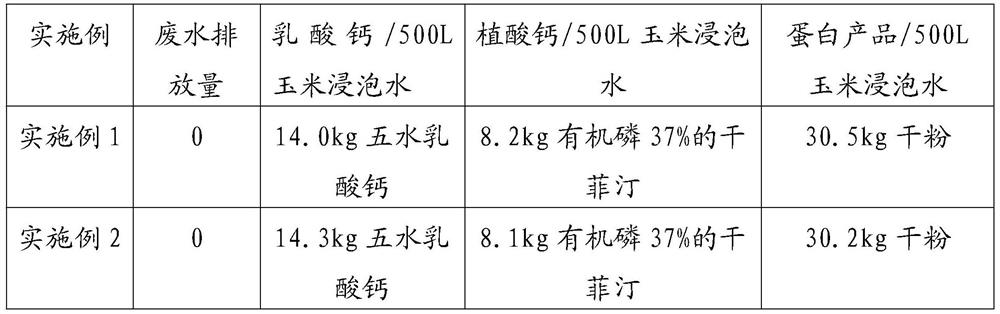

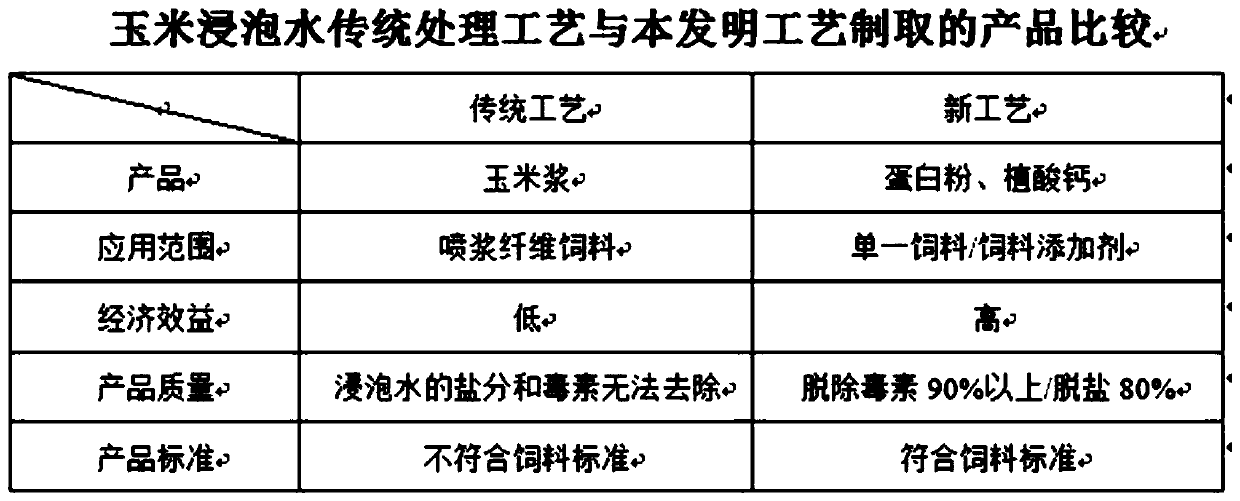

Process method for preparing calcium phytate and calcium lactate by using corn soaking water

ActiveCN113135954AThe realization of the productionTo avoidOrganic compound preparationGroup 5/15 element organic compoundsCALCIUM LACTOBIONATEEnvironmental engineering

The invention relates to the technical field of corn soaking water treatment, in particular to a process method for preparing calcium phytate and calcium lactate by using corn soaking water, which comprises the following steps: (1) settling the corn soaking water to obtain supernate, enabling the supernate to enter an anion resin column, collecting first effluent, enabling the first effluent to enter the anion resin column by using hydrochloric acid as a desorption agent, and collecting a desorption solution; (2) after the first effluent in the step (1) is filtered by a nanofiltration membrane, respectively collecting trapped fluid and permeate; (3) enabling the permeate collected in the step (2) to enter a weakly alkaline anion resin column, collecting a second effluent, enabling a calcium chloride solution as a desorption agent to enter the weakly alkaline anion resin column, and collecting a desorption solution; and (4) drying the trapped fluid in the step (2), and concentrating the second effluent collected in the step (3). According to the process method, the corn soaking water is effectively treated, the calcium phytate and the calcium lactate are obtained, and the discharge of wastewater is greatly reduced.

Owner:ZHUCHENG HAOTIAN PHARMA

Calcium phytate purification method

InactiveCN105524106AHigh puritySimple processGroup 5/15 element organic compoundsPurification methodsDistilled water

The invention relates to a calcium phytate purification method. According to the invention, a calcium phytate crude product is crushed, and is dissolved with saturated hydrochloric acid; filtering is carried out and a filtrate is kept; sodium hydroxide is added into the filtrate until the pH value is higher than 8, while stirring is continuously carried out; filtering is carried out; the filtrate is removed, and a precipitate is kept; the precipitate is washed 2-4 times with distilled water, and is washed 2-4 times with ethanol; and the washed calcium phytate is dried, wherein a drying temperature is controlled at 60-80 DEG C. The calcium phytate provided by the invention has high purity, and can be applied in food and medicine. The process is simple, and the cost is low.

Owner:李智

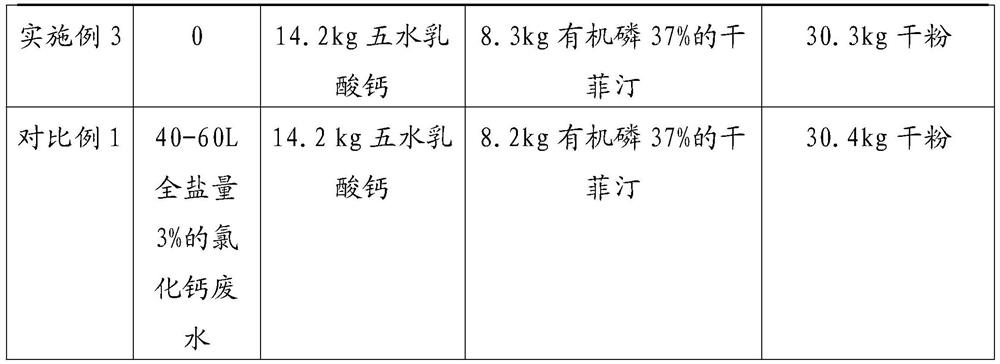

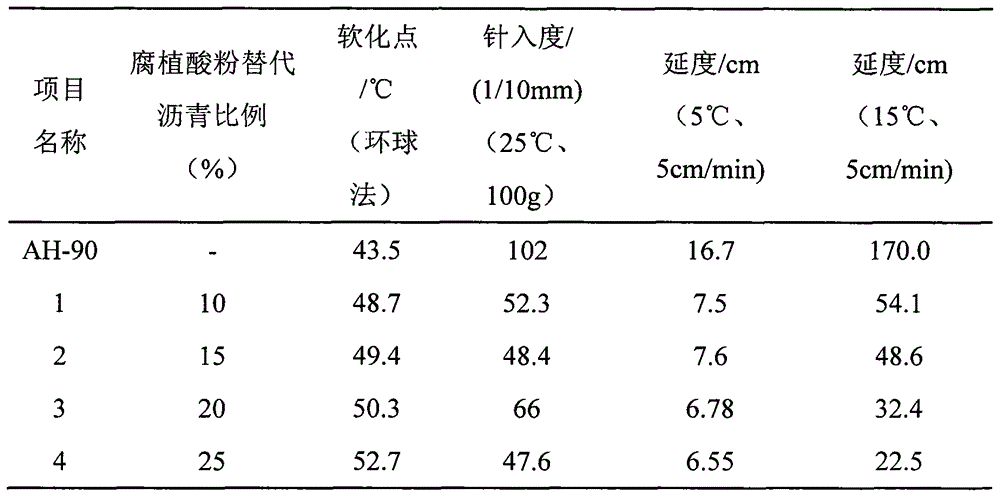

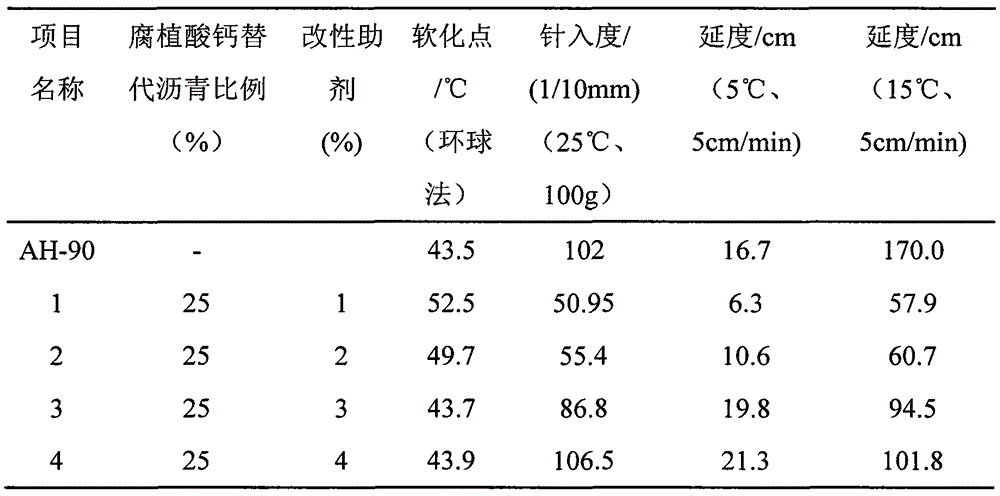

Application technology for humic acid derivatives used as asphalt composition

ActiveCN105985654ALow costAlleviate the shortage of market supplyOrganic chemistryBuilding insulationsCalcium hydroxideRoad surface

The invention relates to a formula and a mixing technology for natural humic acid and derivatives of the natural humic acid used as modifying components of pavement asphalt. The formula and the mixing technology comprise a technology and equipment for complete mixing of humic acid powder or calcium humate generated by a preliminary reaction of humic acid with calcium hydroxide, and asphalt. According to different varieties and application requirements of the asphalt, different formulas can be adopted. The asphalt of the asphalt composition series has the following advantages: the softening point reaches the standard; low-temperature performance is well improved; and standards and practical technologies of relevant modified asphalt are met. The invention provides a high-value-added utilization method for the asphalt used as a pavement binding material. High-value-added utilization of humic acid and cost reduction of modified asphalt have important values on alleviating of the lack of market supply of the asphalt and improvement of high-temperature and low-temperature performances of the asphalt. The technology provided by the invention is a complete set of practical techniques for recycling and high-value-added utilization of solid wastes. The technology provided by the invention has the advantages of widely-available raw materials, simple preparation process, and good economic, social and environmental benefits.

Owner:XIAMEN UNIV

Method for extracting calcium-magnesium phytate from corn soaked liquid

InactiveCN105001257AMake sure to recycleImprove elution efficiencyGroup 5/15 element organic compoundsIon-exchange resinFermentation

The method discloses a method for extracting calcium-magnesium phytate from corn soaked liquid and belongs to the technical field of starch processing. The method includes the following steps that firstly, ion exchange resin is used for adsorbing organic phosphorus in the corn soaked liquid; secondly, after ion exchange resin adsorption is saturate, the organic phosphorus on the ion exchange resin is washed and removed through a hydrochloric acid solution, and a solution containing phosphorus is obtained; thirdly, a calcium hydroxide solution is added in the solution containing phosphorus so that a neutralization reaction can be performed, and finished product liquid is obtained; fourthly, the finished product liquid is filtered and dried so that calcium phytate finished products can be obtained. Compared with the prior art, the method has the advantages that due to the fact that the organic phosphorus in the corn soaked liquid is adsorbed through the ion exchange resin, the problems that because clear limewater is directly added for a neutralization reaction in a traditional method, a large number of calcium ions exist in a solution, and an evaporator scales and cannot be used are solved, meanwhile, only the organic phosphorus in the corn soaked liquid is reduced after the corn soaked liquid passes the ion exchange resin, no other nutrient component are lost, and the method can also be used for preparing medicine, fermentation and fodder.

Owner:SHANDONG DAZONG BIOLOGICAL DEV

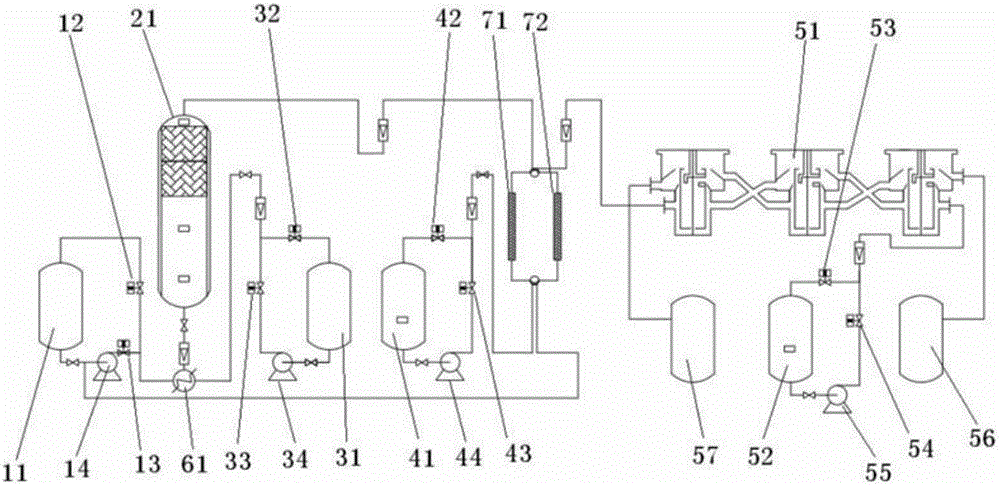

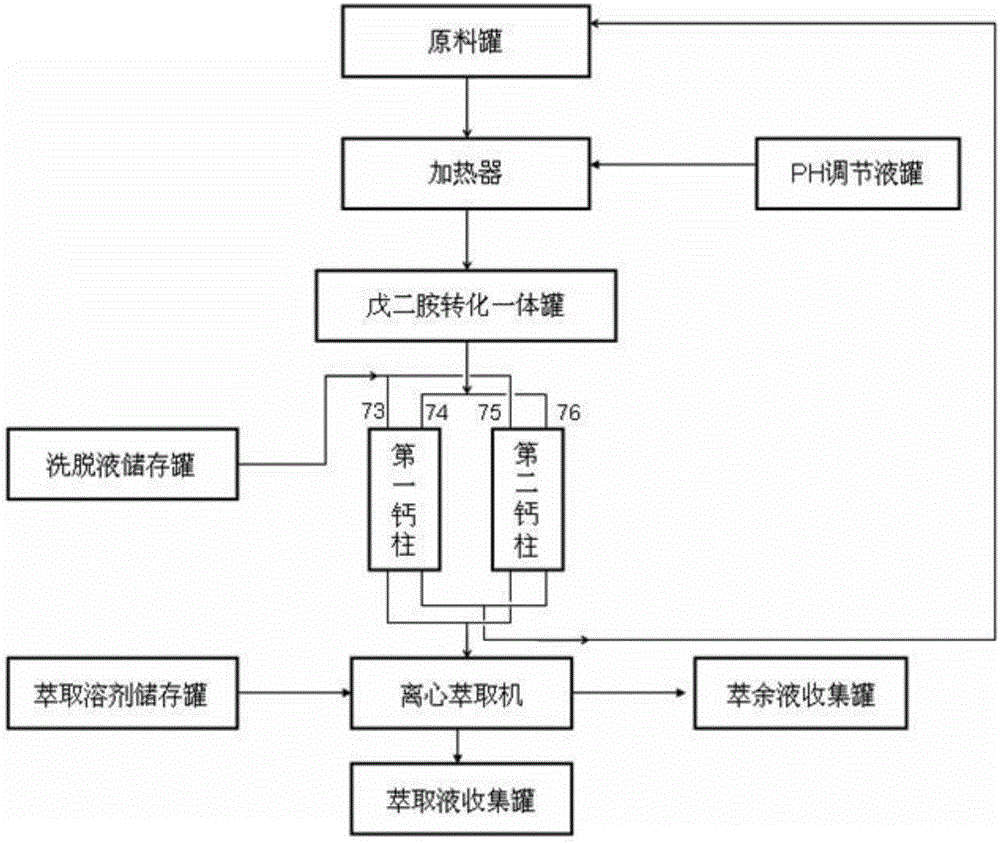

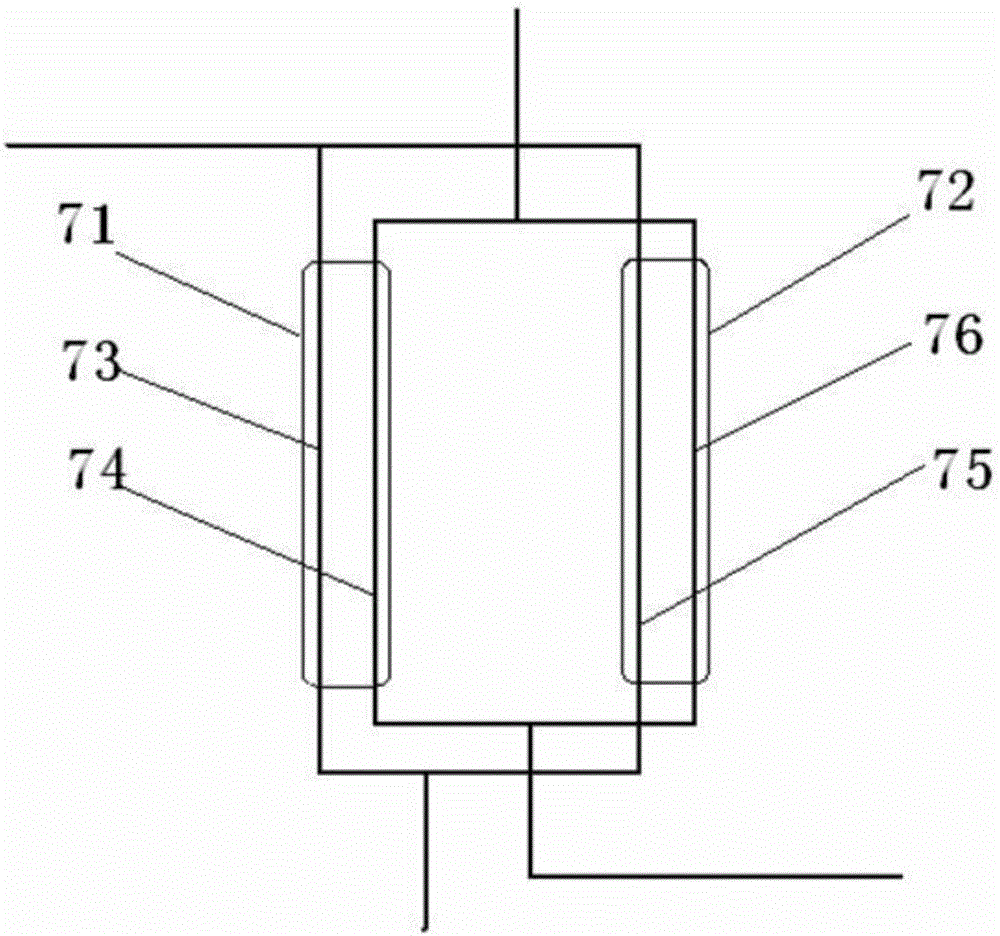

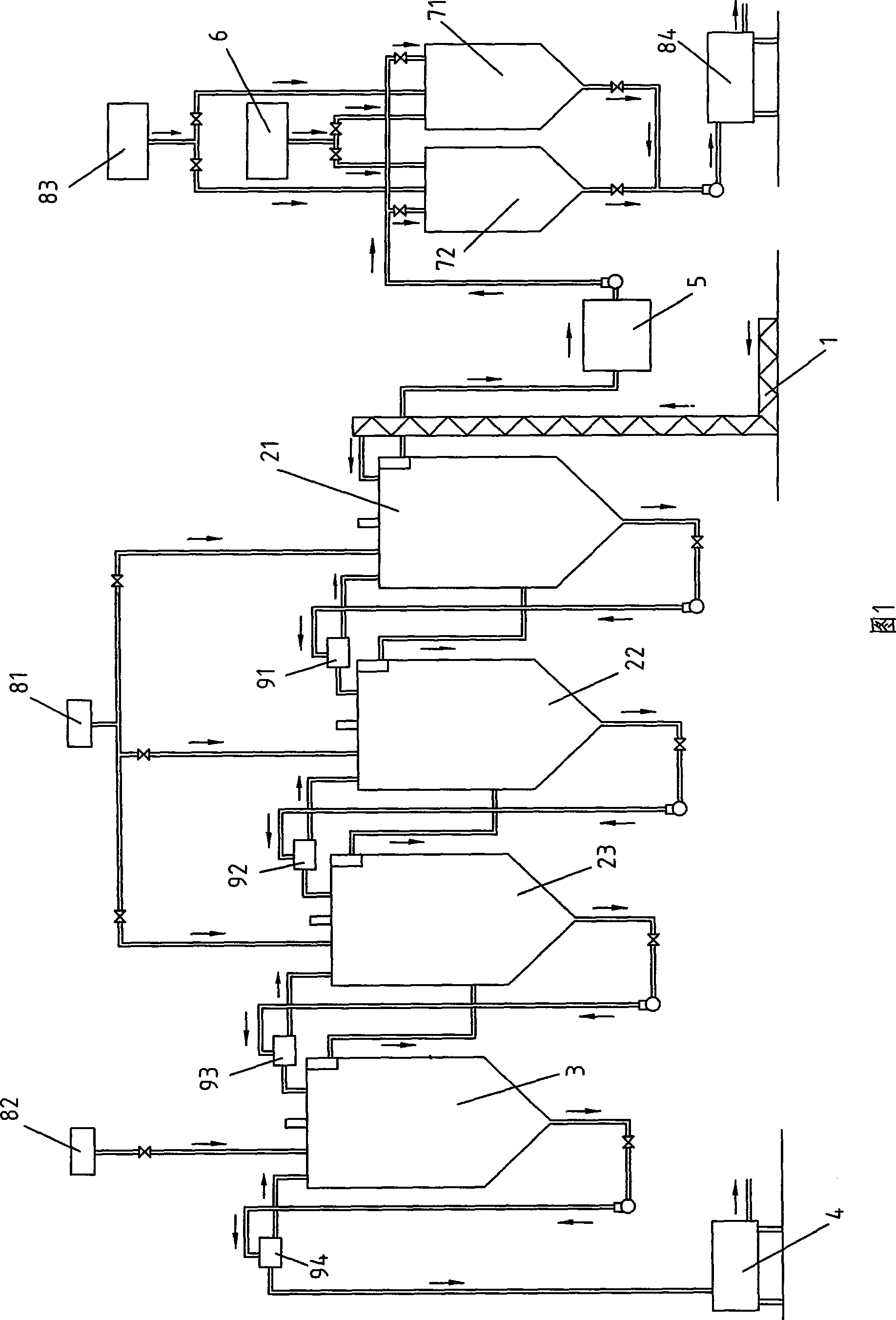

Apparatus for continuous production and extraction of cadaverine via immobilized cells

ActiveCN106367326ASolve the problem of extraction in continuous productionIncrease profitBioreactor/fermenter combinationsAmino compound purification/separationElutionCadaverine

The invention discloses an apparatus for continuous production and extraction of cadaverine via immobilized cells. The apparatus comprises a feed conveying part, a cadaverine converting part, a pH value adjusting part, a column adsorption and elution part and a centrifugal extraction part, wherein a feed tank, an integrated cadaverine conversion tank and a calcium phytate column are in circulation connection via pipelines; a pH value adjusting liquid tank is connected on a pipeline located between the feed tank and integrated cadaverine conversion tank via a pipeline; an eluate storage tank is connected with the calcium phytate column via a pipeline; and a centrifugal extraction machine is connected with the calcium phytate column. Compared with the prior art, the apparatus for continuous production and extraction of cadaverine via the immobilized cells perfectly overcome problems in continuous production and extraction of cadaverine, is applicable to large-scale production and operation of cadaverine, and has the characteristics of simple operation, high equipment utilization rate, stable product quality, sufficient utilization of raw materials, easiness in promotion, etc.

Owner:NANJING UNIV OF TECH

Corn soaking water resource treatment method

InactiveCN110627829ALow costExtraction energy consumption reducedOrganic compound preparationGroup 5/15 element organic compoundsReverse osmosisHigh pressure

The invention relates to the technical field of corn deep processing, particularly to a corn soaking water resource treatment method, which comprises: taking corn soaking water as a raw material; separating out solid insoluble substances and small-particle substances, and filtering and separating out solid substances by a filter press; carrying out anion-cation resin exchange extraction to obtainphytic acid, and further producing calcium phytate; feeding the corn soaking water subjected to resin exchange treatment enter a microfiltration-ultrafiltration-nanofiltration membrane separation system, extracting the concentrated water, and concentrating and drying the soluble proteins in the soaking water to prepare protein powder; and concentrating the clear water subjected to nanofiltration treatment by using a high-pressure reverse osmosis membrane, feeding the concentrated water into a neutralizing tank, adding quick lime, carrying out stirring neutralizing, carrying out filter pressingdehydration, and drying into powder or blocks to obtain the calcium lactate compound. According to the scheme, the raw material source is the remaining soaking wastewater of the corn deep processingproject, so that the raw material cost is low, only the extraction and production operation cost is needed, the industrialization is achieved, the waste is turned into wealth, and the dual benefits ofresource utilization and environmental protection are achieved.

Owner:青岛西海岸第六纪生态农业发展有限公司

High-temperature-resistant metal cutting tool and preparation method thereof

InactiveCN104264027AGood high temperature hardnessPerformance unchangedTurning toolsBenzoic acidSulfite salt

The invention discloses a high-temperature-resistant metal cutting tool and a preparation method thereof. The high-temperature-resistant metal cutting tool comprises the following raw materials in parts by weight: 10-20 parts of a copper-aluminum alloy, 10-30 parts of an iron-titanium alloy, 20-60 parts of styrene, 30-40 parts of methyl benzoic acid, 10-20 parts of sulfite, 2-10 parts of dimyristyl alcohol ester, 30-40 parts of epoxidized soybean oil, 35-45 parts of methoxy polyethylene glycol, 20-30 parts of sodium oleate, 30-80 parts of calcium phytate and 25-35 parts of water glass. The preparation method comprises the following steps: (1) melting the copper-aluminum alloy and the iron-titanium alloy, and cooling for later use; (2) uniformly mixing styrene, methyl benzoic acid, sulfite, sodium oleate, calcium phytate, dimyristyl alcohol ester, epoxidized soybean oil and methoxy polyethylene glycol at 50-60 DEG C, then adding the water glass, and uniformly mixing; and (3) pouring a solution obtained in the step (2) into the step (1), cooling, and then pouring into a cutting tool mold. According to the high-temperature-resistant metal cutting tool disclosed by the invention, the tolerable temperature is 360-380 DEG C, and the hardness is 31-34HRC, so that the high-temperature-resistant metal cutting tool has very good high-temperature hardness and can remain performance at a high temperature.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

Compound fertilizer special for high-activity multi-element wheat and preparation method thereof

PendingCN105949010AImprove the effectInhibition of absorptionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNutrientChemistry

The invention provides a compound fertilizer special for high-activity multi-element wheat and a preparation method thereof. The compound fertilizer is prepared from, by weight, 7-18 parts of humic acid, 20-30 parts of urea, 32-45 parts of monoammonium phosphate, 14-25 parts of potassium chloride, 0.5-3 parts of manganous sulfate, 0.5-3 parts of copper sulfate, 0.5-3 parts of borax, 2-9 parts of sea-foam stone powder, 2-6 parts of a hydrochloric acid solution and 4-12 parts of water. According to the compound fertilizer, humic acid activating treatment is finished through hydrochloric acid, and indissoluble humid acid calcium and magnesium salt are made to be dissoluble calcium and magnesium salt so that crop can absorb and utilize the compound fertilizer better. The product nutrient ratio can meet the fertilizer needing character of the wheat, rich medium trace elements and organic matter are more suitable for wheat growing demands, and the compound fertilizer has the advantages of promoting effect enhancing of the fertilizer, improving, activating and remediating soil, increasing the crop yield and improving the crop quality.

Owner:天津芦阳肥业股份有限公司

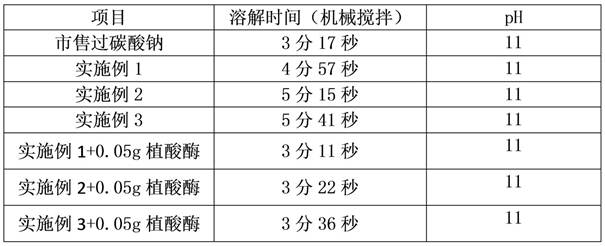

Coated sodium percarbonate material as well as preparation method and application thereof

ActiveCN112877152ANo pollution in the processHigh humidity stabilityNon-surface-active detergent compositionsDetergent mixture composition preparationPhytasePhysical chemistry

The invention belongs to the technical field of washing assistants, and particularly relates to a coated sodium percarbonate material as well as a preparation method and application thereof. According to the invention, a reversible coating material layer is formed outside sodium percarbonate to prepare the coated sodium percarbonate material with high moisture-proof stability and good release performance. Magnesium phytate or calcium phytate formed by sodium phytate and magnesium sulfate, magnesium chloride or calcium chloride is used as a coating layer, and the coating layer is wrapped by a bio-based material and is environmentally friendly and free of pollution. And the wrapped sodium percarbonate is difficult to dissolve in water, has high moisture-proof stability and can be stored for a long time. During use, the wrapping layer can be decomposed through phytase, and sodium percarbonate is released. The problems of sodium percarbonate coating and difficult coating decomposition are thoroughly solved.

Owner:河南省生物基材料产业研究院有限公司

Oil preparation method using rice bran

InactiveCN101396050AExtended shelf lifeEasy to storeEdible oils/fatsFood preparationAcid valueRice Bran Extract

The invention relates to a method used for preparing oil by rice bran, belonging to the extraction process of rice bran oil. The existing method used for preparing the rice bran oil directly extracts the rice bran oil extracted from fresh rice bran; the refreshment of fresh rice bran is difficult, thus leading the industry of extracting the rice bran oil from the rice bran to be gradually atrophied and a plurality of resources to be wasted. The invention provides a method used for preparing oil from the rice bran; rice bran and acid solution are taken ready for use; the method is characterized in that the sequence that the wet rice bran and acid solution are separated, the calcium phytate is removed and the rice bran oil is extracted. The method firstly removes the calcium phytate in the rice bran and extracts the rice bran oil subsequently, thus solving the refreshment problem of the fresh rice bran. When the rice bran oil is extracted from the rice bran, the acid value in the rice bran is low, thus reducing the corrosion on the equipment.

Owner:沈善勋

High-efficiency phosphate-solubilizing Clostridium butyricum A5-4 and applications

InactiveCN101851596BIncrease available phosphorus contentPromote growthBio-organic fraction processingBacteriaBiotechnologySludge

The invention discloses high-efficiency phosphate-solubilizing Clostridium butyricum, a preparation method and application thereof, belonging to the technical field of agricultural microorganisms. In the invention, one high-efficiency phosphate-solubilizing Clostridium butyricum A5-4 strain is obtained through separation, and the strain is preserved in China Center for Type Culture Collection (CCTCC for short), wherein the preservation number is CCTCC NO: Ma010052. The bacterium is separate from the substrate sludge of a septic tank and has the capacity of efficiently dissolving calcium phosphate and calcium phytate under the anaerobic condition. The bacterium has wide nutrient requirement range, easy cultivation, low cost and storage property and can not cause environmental pollution after being reapplied to the environment. The strain can be developed into a novel microorganism agent applied to aquatic crop cultivation or aquaculture.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com