Apparatus for continuous production and extraction of cadaverine via immobilized cells

A technology for immobilized cells and extraction of pentamethylenediamine, which is applied in the field of continuous production and extraction of pentamethylenediamine by immobilized cells, and in the field of compound production and extraction devices, can solve the problems of complex separation, high cell toxicity, and non-reusable cells. Achieve stable product quality, high equipment utilization, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

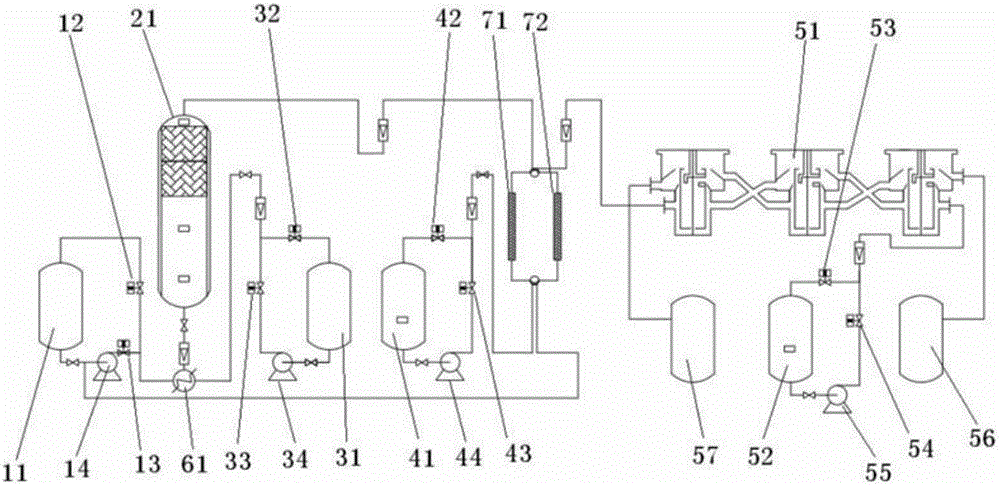

[0044] Citing the patented method and steps of immobilizing cells, the immobilized cells are evenly placed in the immobilized cell column 25 of the pentamethylenediamine conversion integrated tank 21 . In order to ensure that the immobilized cells have a larger contact area, the immobilized cell bacteria column 25 is assembled from multi-layer uniform stainless steel wire mesh column boxes. The temperature detection feedback system 23 regulates the power of the heater 61 to ensure that the temperature of the lysine salt solution entering the pentamethylenediamine conversion integrated tank 21 is 37° C., and the pH detection feedback system 22 adjusts the third solenoid valve 32 and the fourth solenoid valve 33 to ensure that each The ph of the lysine salt solution entering the pentamethylenediamine conversion integrated tank 21 for the first time is the same. Pyridoxal phosphate is added to the feed liquid at a ratio of 3:1000 (mmol:ml), and the flow rate of the raw material t...

Embodiment 2

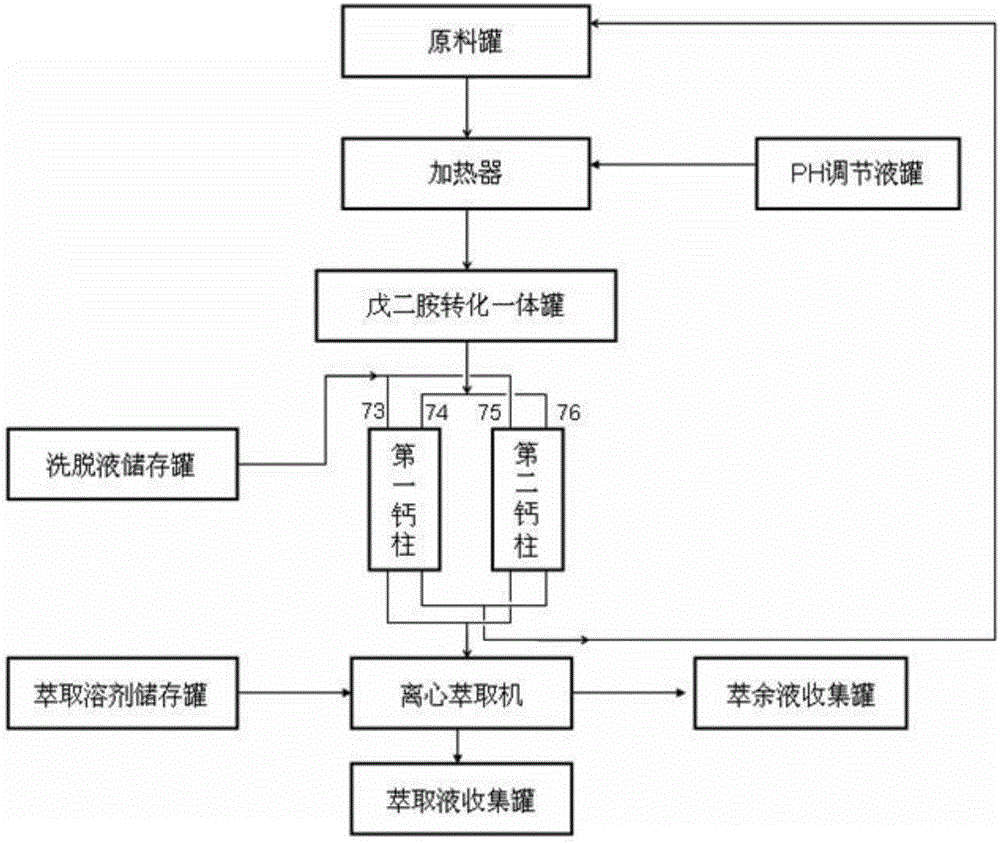

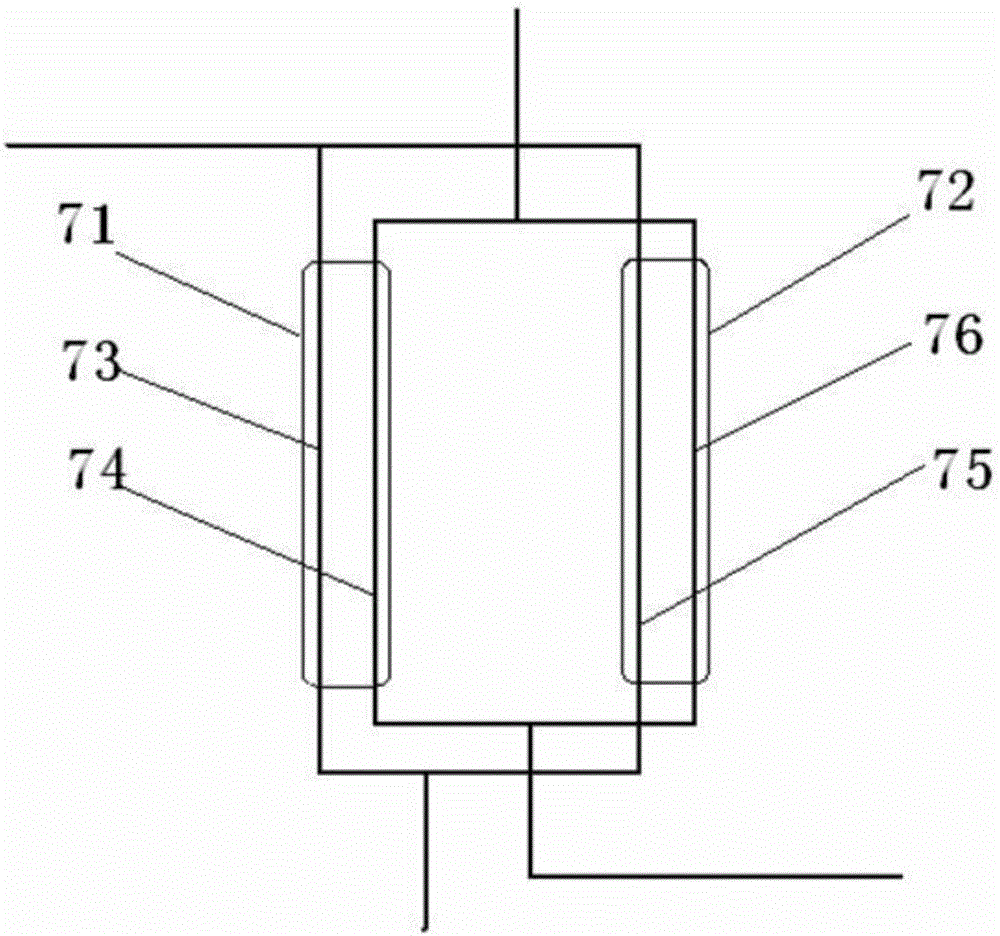

[0048] When the solution containing pentamethylenediamine flows through the calcium phytate column, the calcium phytate column can adsorb the pentamethylenediamine in the solution on the calcium phytate column, reducing the concentration of pentamethylenediamine in the solution and lowering the pH of the solution at the same time. However, the adsorption is not very stable. After experiments, it was found that part of the pentamethylenediamine adsorbed by the calcium phytate column can be eluted with a solution. It can also re-adsorb pentamethylenediamine to achieve the purpose of recycling. First, use the same concentration and volume of pentamethylenediamine conversion solution to flow through the calcium phytate column to absorb pentamethylenediamine, and then use solutions with pH of 4.5, 7.0, and 13.4 to elute the pentamethylenediamine on the calcium phytate column at the same flow rate. Pentylenediamine. The concentration of the solution before and after passing through...

Embodiment 3

[0052] First turn on the three extraction centrifuges in order, and adjust the frequency of the motor to 45hz. After the extraction centrifuges are stable and normal, first pump the heavy phase from the heavy phase inlet at a flow rate of 100ml / min, and wait for the liquid to flow out from the heavy phase outlet. Immediately pump the light phase from the light phase inlet at a flow rate of 100ml / min, wait for 15-20 minutes after the output of the heavy and light phases is stable, start recording the volumes of the heavy and light phases, and re-collect the heavy and light phases from the outlet Liquid and measure the volume. After running for a period of time, turn off the pump at the entrance of the heavy and light two phases at the same time. When there is no liquid flowing out of the heavy and light two phases, turn off the motor of the centrifugal extractor, and finally let off a small amount of liquid in the centrifugal extractor. . Measure the volume of feed liquid (heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com