Composite flame retardant and preparation method thereof

A composite flame retardant and compound technology, which is applied in the field of composite flame retardants and their preparation, can solve the problems of dialysis, frost spraying, non-aging resistance, etc., and achieve the effects of simple preparation process, bright application prospect and good flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

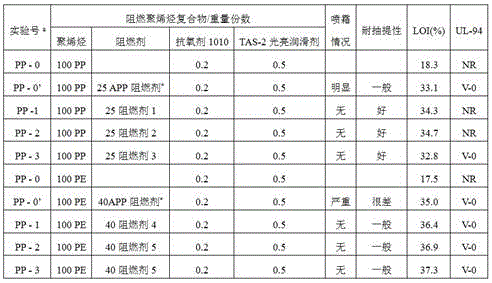

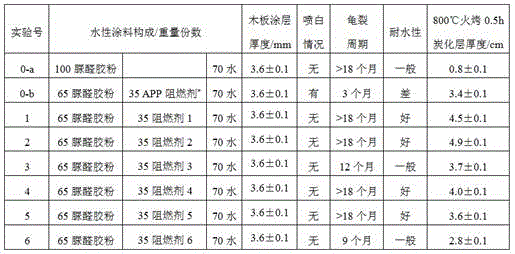

Examples

Embodiment 1

[0020] First put 1000 grams of chitosan, 1650 grams of phytic acid, 100 grams of water, 2350 grams of melamine, and 400 grams of white carbon black into a reaction kettle equipped with condensation, reflux, stirring and temperature control systems, and mechanically stir and mix evenly. And program temperature control to make the resulting mixture react at 105°C for 3 hours; then, add 5000 grams of acetic anhydride and 300 grams of 3-aminopropyltrimethoxysilane while stirring, continue to mechanically stir, mix well, and control the temperature to make the second The resulting mixture was reacted at 145°C for 0.5h; finally, 150g of urea was added, stirred and mixed continuously, and the mixture obtained three times was solidified and reacted at 250-260°C for 0.5h, discharged, cooled, pulverized, and passed through a 200-mesh sieve to obtain urea. Fuel 1.

Embodiment 2

[0022] First put 1000 grams of chitosan, 2000 grams of phytic acid, 200 grams of water, 1970 grams of melamine, and 300 grams of white carbon black into a reaction kettle equipped with condensation, reflux, stirring and temperature control systems, and mechanically stir and mix evenly. And program temperature control to make the resulting mixture react at 120°C for 2 hours; then, add 3300 grams of acetic anhydride and 500 grams of 3-aminopropyltrimethoxysilane while stirring, continue to mechanically stir, mix well, and control the temperature to make the second The resulting mixture was reacted at 135°C for 0.75h; finally, 200g of urea was added, stirred and mixed continuously and the mixture obtained three times was solidified and reacted at 250-260°C for 0.5h, discharged, cooled, and crushed through a 200-mesh sieve to obtain a flame retardant Agent 2.

Embodiment 3

[0024] First put 1000 grams of chitosan, 2400 grams of phytic acid, 300 grams of water, 1600 grams of melamine, and 200 grams of white carbon black into a reaction kettle equipped with condensation, reflux, stirring and temperature control systems, and mechanically stir and mix evenly. And program temperature control to make the resulting mixture react at 135 ° C for 1 hour; then, add 2600 grams of acetic anhydride and 100 grams of 3-aminopropyltrimethoxysilane while stirring, continue to mechanically stir, mix well, and control the temperature to make the second The resulting mixture was reacted at 125°C for 1 hour; finally, 250 grams of urea was added, continuously stirred and mixed, and the mixture obtained three times was solidified and reacted at 250-260°C for 0.5 hours, discharged, cooled, and crushed through a 200-mesh sieve to obtain a flame retardant 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com