Oil preparation method using rice bran

A rice bran oil and rice bran technology, applied in the field of rice bran oil extraction technology, can solve the problems of difficult control, waste of resources, air pollution, etc., and achieve the effects of prolonging the fresh-keeping period, prolonging the service life, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

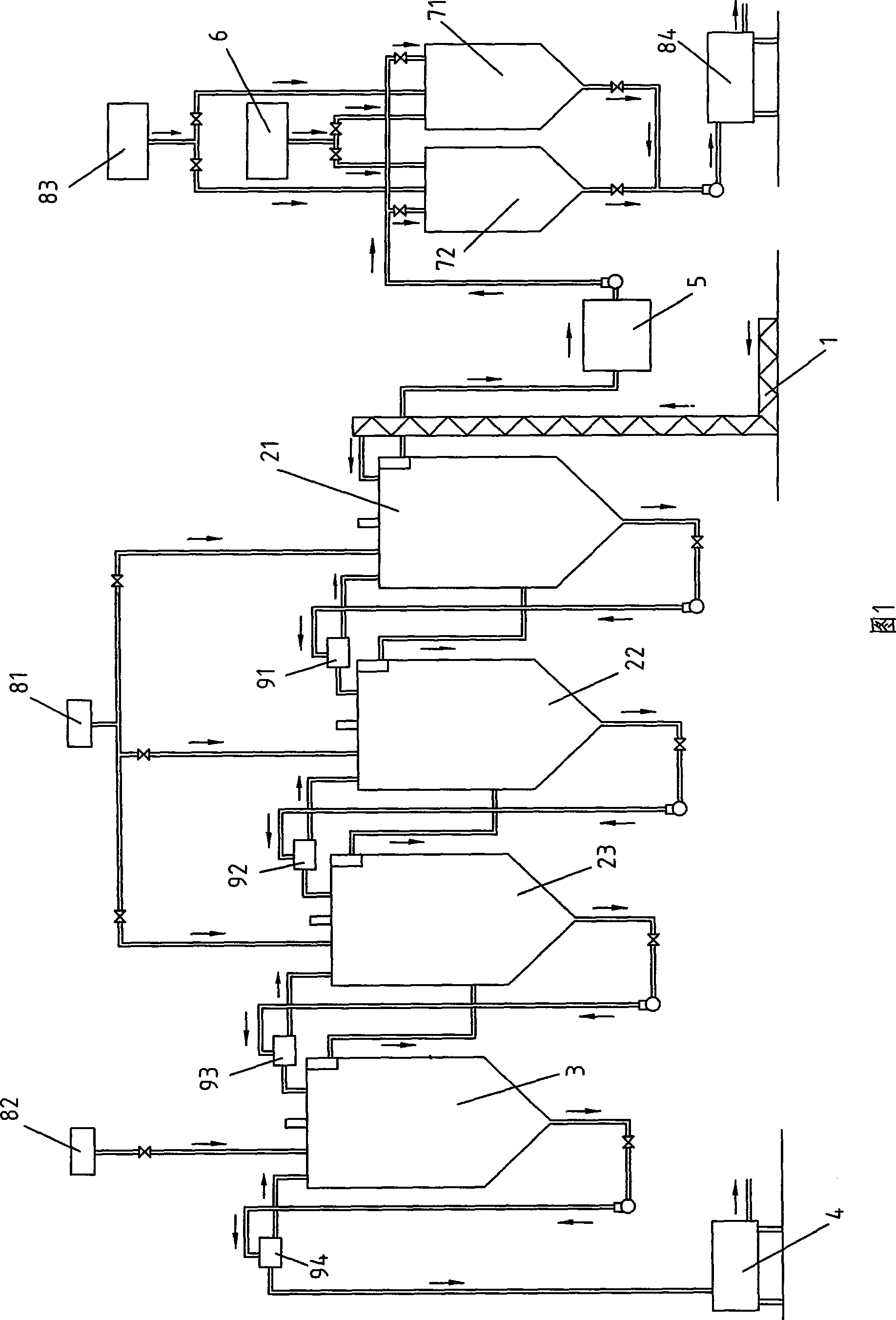

[0022] Referring to Fig. 1 , the rice bran is transported into No. 1 pickling pot 21 by conveyor 1. A stirring paddle is arranged in No. 1 pickling pot 21, and acid solution is filled inside. The rice bran is stirred in the No. 1 pickling pot 21 and settles down. After soaking in the No. 1 pickling pot 21 for about one minute, the rice bran is pumped to the No. 1 vibrating screen 91 through the pipeline at the bottom. The sieve 91 separates the rice bran from the acid solution, and the rice bran enters the No. 2 pickling pot 22 along with the pipeline, while the acid solution returns to the No. 1 pickling pot 21 along with the pipeline.

[0023] The rice bran that enters No. 2 pickling pot 22 still sinks down through stirring, and the rice bran is soaked in No. 2 pickling pot 22 for about 1 minute, and then it is pumped to No. 2 vibrating screen 92 through the pipeline at the bottom. No. vibrating screen 92 separates rice bran and acid solution, and rice bran enters No. 3 pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com