Coated sodium percarbonate material as well as preparation method and application thereof

A technology of sodium percarbonate and coating, which is applied in chemical instruments and methods, preparation of detergent mixture compositions, organic peroxy/inorganic peroxy compound compositions, etc., can solve the problems of difficulty in long-term storage, stability to be improved, and the like, To achieve the effect of high humidity resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

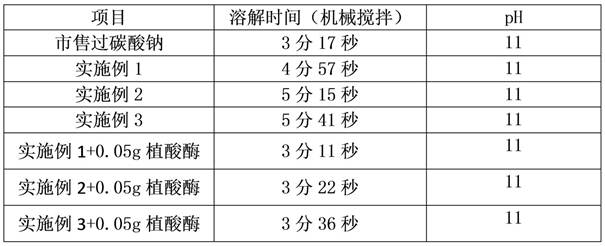

Examples

Embodiment 1

[0035] A kind of preparation method of coating sodium percarbonate material, concrete steps are as follows:

[0036] (1) Take 0.125kg of sodium phytate to prepare a sodium phytate solution with a mass fraction of 5%, and take 0.45kg of magnesium sulfate to prepare a magnesium sulfate solution with a mass fraction of 15%;

[0037] (2) Preheat the temperature of the fluidized bed to 70°C, put 100kg of sodium percarbonate in the fluidized bed, spray the sodium phytate solution in step (1) on the sodium percarbonate, and raise the temperature to 120°C for One-time coating requires a coating thickness of 0.1mm to 0.3mm. Among them, the fluidized bed operating speed is 4 tons / h, and the liquid spraying speed is 1 cubic meter / h. During operation, the fluidized bed operating speed can be adjusted according to the actual situation. To adjust, the particle size of sodium percarbonate coated once in step (2) is between 1mm-3mm;

[0038] (3) Continue to spray the magnesium sulfate soluti...

Embodiment 2

[0041] A kind of preparation method of coating sodium percarbonate material, concrete steps are as follows:

[0042] (1) Take 0.175kg of sodium phytate to prepare a sodium phytate solution with a mass fraction of 7%, and take 0.3kg of magnesium sulfate to prepare a magnesium sulfate solution with a mass fraction of 10%;

[0043] (2) Preheat the temperature of the fluidized bed to 75°C, put 100kg of sodium percarbonate in the fluidized bed, spray the sodium phytate solution in step (1) on the sodium percarbonate, and raise the temperature to 110°C for One-time coating requires a coating thickness of 0.1mm to 0.3mm. Among them, the fluidized bed operating speed is 4 tons / h, and the liquid spraying speed is 1 cubic meter / h. During operation, the fluidized bed operating speed can be adjusted according to the actual situation. To adjust, the particle size of sodium percarbonate coated once in step (2) is between 1mm-3mm;

[0044] (3) Continue to spray the magnesium sulfate solution ...

Embodiment 3

[0047] A kind of preparation method of coating sodium percarbonate material, concrete steps are as follows:

[0048] (1) Take 0.25kg of sodium phytate to prepare a sodium phytate solution with a mass fraction of 10%, and take 0.36kg of magnesium sulfate to prepare a magnesium sulfate solution with a mass fraction of 12%;

[0049] (2) Preheat the temperature of the fluidized bed to 80°C, put 100kg of sodium percarbonate in the fluidized bed, spray the sodium phytate solution in step (1) on the sodium percarbonate, and raise the temperature to 130°C for One-time coating requires a coating thickness of 0.1mm to 0.3mm. Among them, the fluidized bed operating speed is 4 tons / h, and the liquid spraying speed is 1 cubic meter / h. During operation, the fluidized bed operating speed can be adjusted according to the actual situation. To adjust, the particle size of sodium percarbonate coated once in step (2) is between 1mm-3mm;

[0050] (3) Continue to spray the magnesium sulfate soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com