Application technology for humic acid derivatives used as asphalt composition

A technology of humic acid and derivatives, applied in building structures, building components, building insulation materials, etc., can solve the problems of unknown asphalt components and asphalt modification, so as to alleviate the market supply of asphalt and improve high and low temperature performance. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Put the humic acid in an oven at 95°C and dry it to constant weight for about 10 hours.

[0023] (2) Humic acid powder is added in the vacuum kneader according to the pitch mass ratio (the same below) as 10%, 15%, 25%, and 30%, and the kneader material temperature is set to 100°C, and the kneading time is 60min. The vacuum pump was turned on during the period of ~20min and 40~60min.

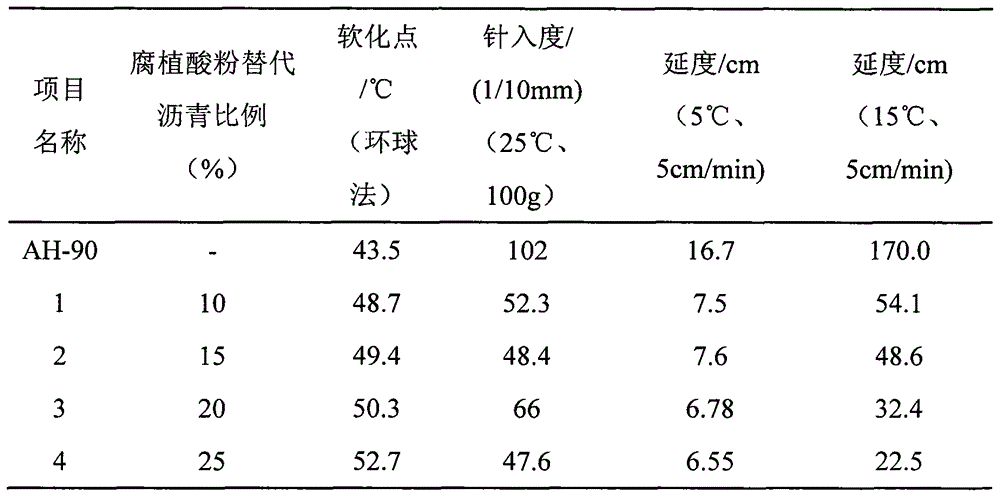

[0024] (3) The obtained samples were tested for softening point (standard GB / T 4507-1999, the same below), penetration (standard GB / T 4509-2010, the same below), ductility (standard GB / T 4508-2010, the same below), The same) performance index determination, the results are listed in Table 1.

[0025] Table 1 Summary table of results of Example 1

[0026]

Embodiment 2

[0028] (1) Humic acid and calcium hydroxide emulsion are reacted to form calcium humate, and the pH is adjusted to 9-10, and placed in an oven at 80-100°C to dry to constant weight.

[0029] (2) Dry the calcium humate and grind it into powder with a pulverizer.

[0030] (3) Add a certain quality of AH-90 asphalt into a stainless steel container, and heat it on a heating plate to 100°C to melt the asphalt into a slurry.

[0031] (4) The auxiliary agent is added in the stainless steel cup according to the addition mass ratio of 3%.

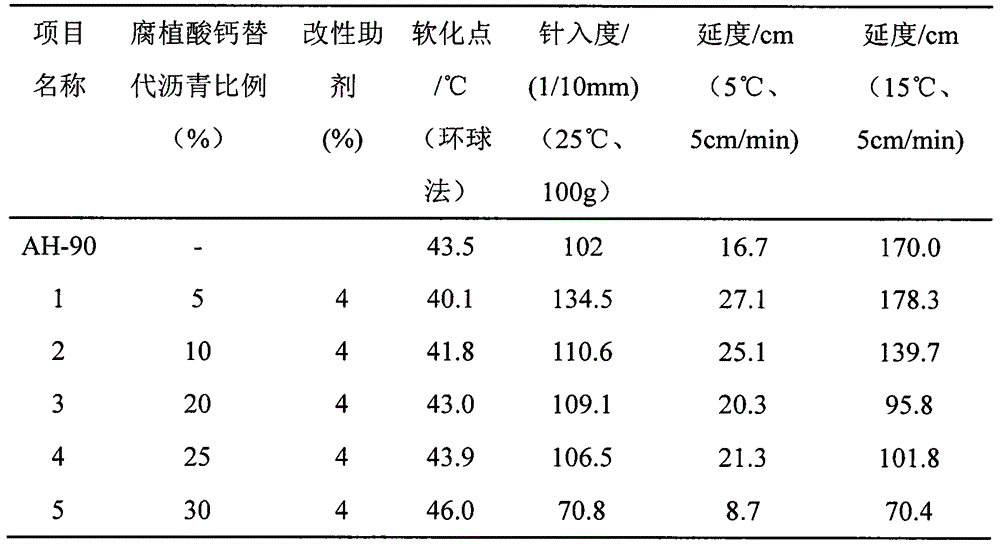

[0032] (5) Stir and mix with a high-speed shear emulsifier, set the rotating speed to 5000r / min, and set the stirring time to 60min. The calcium humate powder is added in a stainless steel cup according to the addition mass ratio of 5%.

[0033] (6) Measure the softening point, penetration and ductility performance indexes of the obtained samples, and repeat the above steps to determine the addition experiment of 10%, 20%, 25% and 30% additive mas...

Embodiment 3

[0037] (1) Dry the calcium humate and grind it into powder with a pulverizer.

[0038] (2) Add a certain quality of AH-90 asphalt into a stainless steel container, and heat it on a heating plate to 100°C to melt the asphalt into a slurry.

[0039] (3) Stir and mix with a high-speed shear emulsifier, and set the rotating speed to 5000r / min. According to the mass fraction of 25%, the corresponding mass of calcium humate powder is weighed and added to a stainless steel container. Set the stirring time to 60min.

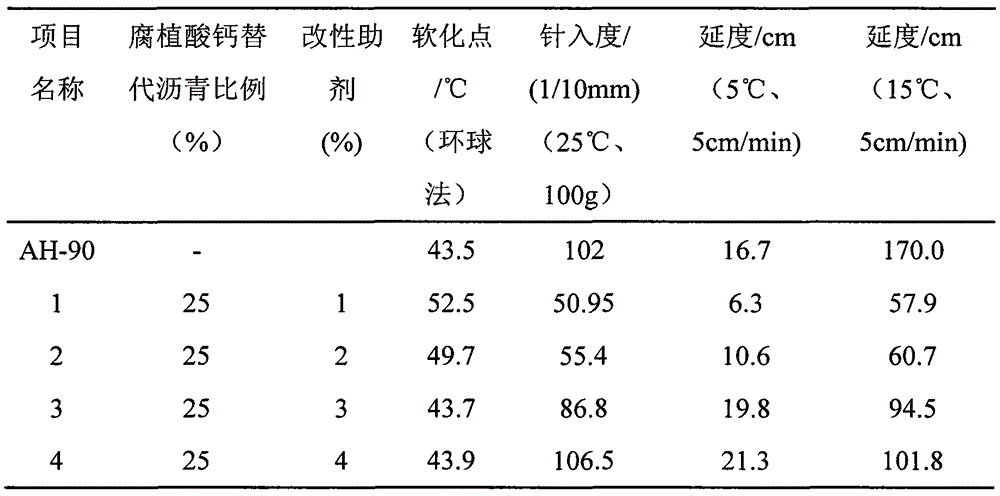

[0040] (4) The auxiliary agent is added in the stainless steel cup according to the added mass of 1%.

[0041] (5) Determination of softening point, penetration and ductility performance indexes of the obtained samples. Repeat the above steps to measure the addition experiment of 2%, 3% and 4% additive mass fraction, and the results are listed in Table 3.

[0042] Table 3 Example 3 result summary table

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com