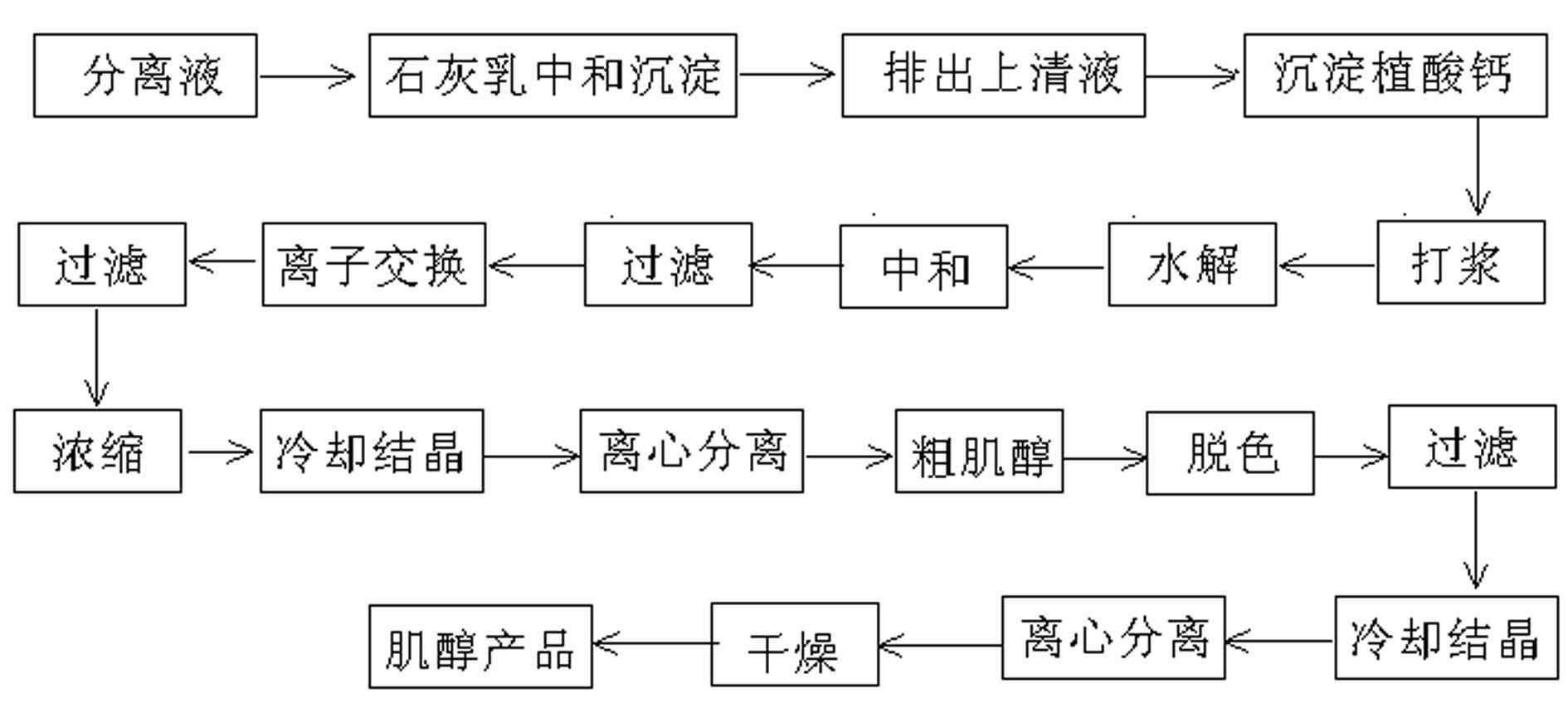

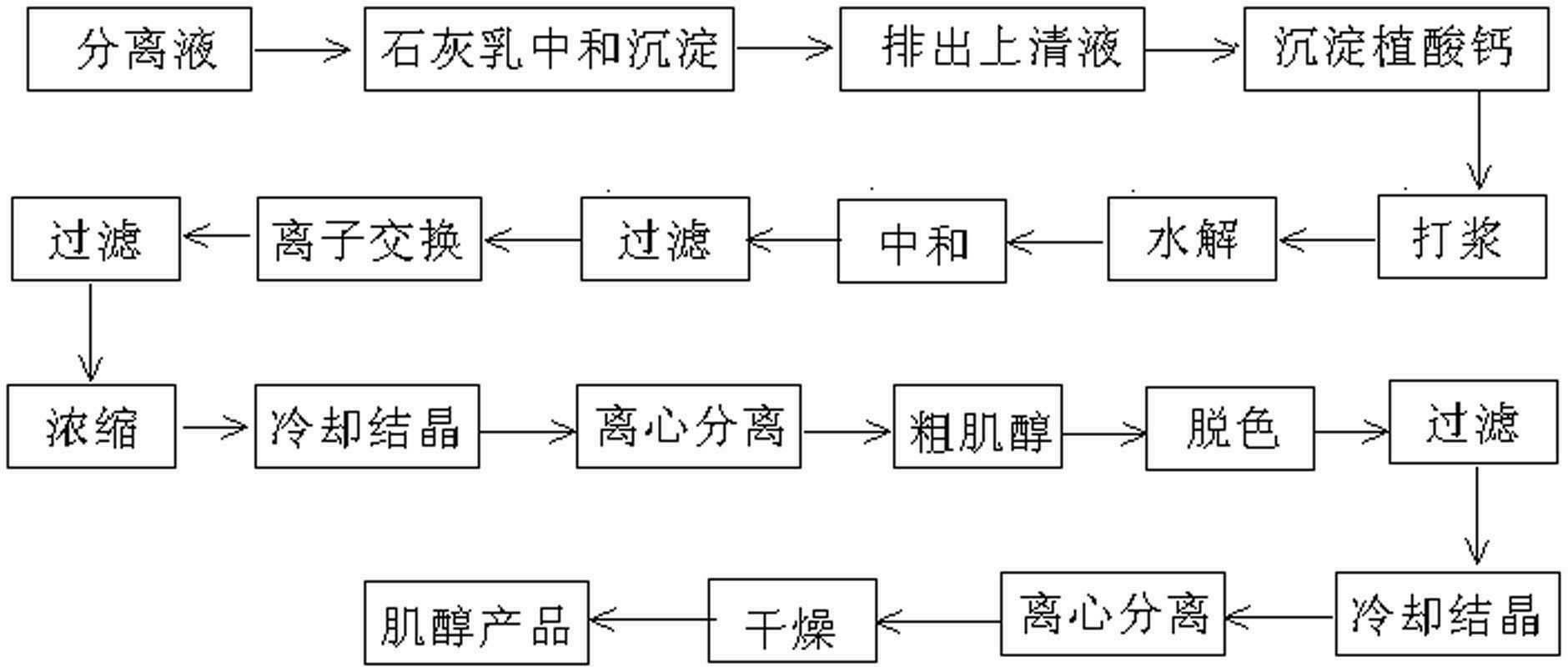

Method for preparing inositol from corn steep liquor

A corn steep liquor, inositol technology, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low production efficiency of inositol, high energy consumption, large investment in production equipment, etc. Freeze or dry drying, low operating temperature, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using flat-plate ultrafiltration membrane equipment, using ultrafiltration membrane separation technology to separate corn soaking liquid into permeate (low molecular weight separation liquid with molecular weight less than 5000) and retentate liquid (high molecular weight separation liquid with molecular weight greater than 5000), Add milk of lime to the permeate, a neutralization reaction occurs, calcium phytate precipitates are formed, and the supernatant is discharged. The membrane material of the flat-plate ultrafiltration membrane equipment is PE, and the relative cut-off molecular weight of the ultrafiltration membrane is 20KD.

[0022] After the calcium phytate precipitate is generated, beating is performed directly, and the precipitate is in the form of water paste at this time.

[0023] In the hydrolysis step, the pressure was 490 kPa. If normal pressure hydrolysis is adopted, the hydrolysis speed is slow, the cycle is long, and the yield is low. From the pe...

Embodiment 2

[0030] Using flat-plate ultrafiltration membrane equipment, using ultrafiltration membrane separation technology to separate corn soaking liquid into permeate (low molecular weight separation liquid with molecular weight less than 5000) and retentate liquid (high molecular weight separation liquid with molecular weight greater than 5000), Add milk of lime to the permeate, a neutralization reaction occurs, calcium phytate precipitates are formed, and the supernatant is discharged. The membrane material of the flat-plate ultrafiltration membrane equipment is PE, and the relative cut-off molecular weight of the ultrafiltration membrane is 20KD.

[0031] After the calcium phytate precipitate is generated, beating is performed directly, and the precipitate is in the form of water paste at this time.

[0032] In the hydrolysis step, the pressure was 520 kPa. If normal pressure hydrolysis is adopted, the hydrolysis speed is slow, the cycle is long, and the yield is low. From the pe...

Embodiment 3

[0040] Using flat-plate ultrafiltration membrane equipment, using ultrafiltration membrane separation technology to separate corn soaking liquid into permeate (low molecular weight separation liquid with molecular weight less than 5000) and retentate liquid (high molecular weight separation liquid with molecular weight greater than 5000), Add milk of lime to the permeate, a neutralization reaction occurs, calcium phytate precipitates are formed, and the supernatant is discharged. The membrane material of the flat-plate ultrafiltration membrane equipment is PE, and the relative cut-off molecular weight of the ultrafiltration membrane is 20KD.

[0041] After the calcium phytate precipitate is generated, beating is performed directly, and the precipitate is in the form of water paste at this time.

[0042] In the hydrolysis step, the pressure was 588 kPa. If normal pressure hydrolysis is adopted, the hydrolysis speed is slow, the cycle is long, and the yield is low. From the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com