Absorption catalyst for desulfurization of smoke gas and preparation method thereof

A catalyst and flue gas technology, applied in the field of absorbing catalyst and its preparation, can solve the problems of secondary pollution, low cost and high construction cost, and achieve the effects of saving cost, reducing cost and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: the fineness is 80-100 mesh carrier γ-Al 2 o 3 , impregnated in Ce(NO 3 ) 3 In deionized aqueous solution, Ce(NO 3 ) 3 The dosage is CeO 2 Calculation, for γ-Al 2 o 3 3% of the mass, stirred for 5 hours, heated and stirred at 80°C for 1 hour, then dried in an oven at 110°C for 12 hours, and roasted in a muffle furnace at 500°C for 5 hours to obtain the intermediate CeO 2 / γ-Al 2 o 3 ; then impregnate the intermediate in Cu(NO 3 ) 2 In aqueous solution, Cu(NO 3 ) 2 The amount calculated as CuO as γ-Al 2 o 3 10% of the mass, stirred for 5 hours, heated and stirred at 100°C for 0.5 hours, then dried in an oven at 110°C for 12 hours, and baked in a muffle furnace at 500°C for 5 hours to obtain CuO-CeO 2 / γ-Al 2 o 3 Absorption catalyst for flue gas desulfurization.

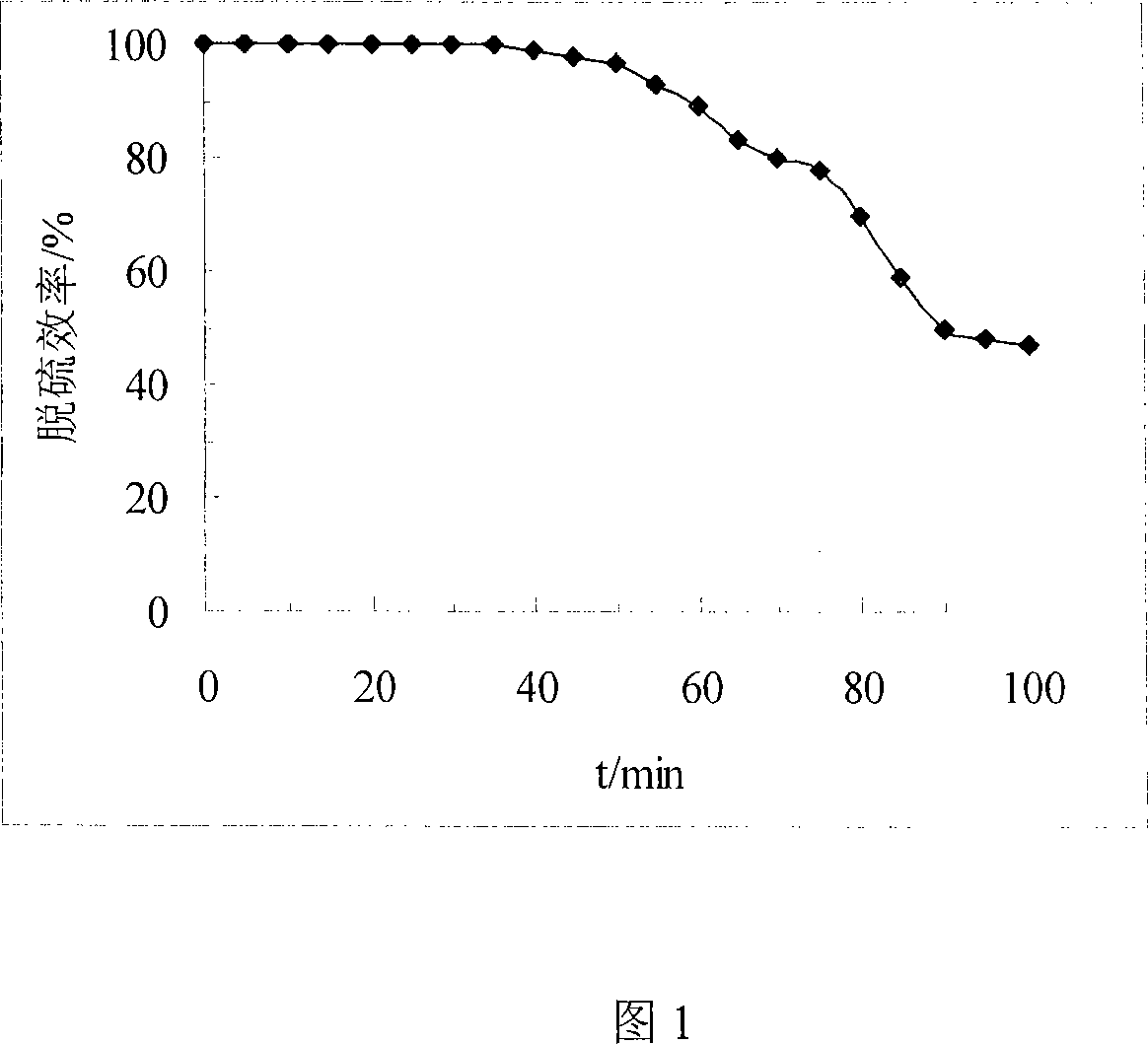

[0026] Use the prepared absorption desulfurization catalyst to desulfurize the flue gas of the 410t / h boiler, and the flue gas outlet of the boiler is SO 2 The concentration is 1658...

Embodiment 2

[0027] Example 2: the fineness is 80-100 mesh carrier γ-Al 2 o 3 , impregnated in Ce(NO 3 ) 3 In deionized aqueous solution, Ce(NO 3 ) 3 The dosage is CeO 2 Calculation, for γ-Al 2 o 3 3% of the mass, stirred for 5 hours, heated and stirred at 80°C for 1 hour, then dried in an oven at 110°C for 12 hours, and roasted in a muffle furnace at 500°C for 5 hours to obtain the intermediate CeO 2 / γ-Al 2 o 3 ; then impregnate the intermediate in Cu(NO 3 ) 2 In aqueous solution, Cu(NO 3 ) 2 The amount calculated as CuO as γ-Al 2 o 3 10% of the mass, stirred for 5 hours, heated and stirred at 100°C for 0.5 hours, then dried in an oven at 110°C for 12 hours, and baked in a muffle furnace at 500°C for 5 hours to obtain CuO-CeO 2 / γ-Al2 o 3 Absorption catalyst for flue gas desulfurization.

[0028] Using a new type of absorption desulfurization catalyst for flue gas desulfurization of 220t / h boiler, boiler flue gas outlet SO 2 The concentration is 3550mg / m 3 , The flue g...

Embodiment 3

[0029] Example 3: the fineness is 80-100 mesh carrier γ-Al 2 o 3 , impregnated in Ce(NO 3 ) 3 In deionized aqueous solution, Ce(NO 3 ) 3 The dosage is CeO 2 Calculation, for γ-Al 2 o 3 3% of the mass, stirred for 5 hours, heated and stirred at 80°C for 1 hour, then dried in an oven at 110°C for 12 hours, and roasted in a muffle furnace at 500°C for 5 hours to obtain the intermediate CeO 2 / γ-Al 2 o 3 ; then impregnate the intermediate in Cu(NO 3 ) 2 In aqueous solution, Cu(NO 3 ) 2 The amount calculated as CuO as γ-Al 2 o 3 10% of the mass, stirred for 5 hours, heated and stirred at 100°C for 0.5 hours, then dried in an oven at 110°C for 12 hours, and baked in a muffle furnace at 500°C for 5 hours to obtain CuO-CeO 2 / γ-Al 2 o 3 Absorption catalyst for flue gas desulfurization,

[0030] Use a new type of absorption desulfurization catalyst to desulfurize the flue gas of a 130t / h boiler, and the flue gas outlet of the boiler is SO 2 The concentration is 5720m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com