Double-oxidation ammonia desulfurization process and device

A double ammonia oxidation method and a desulfurization technology technology, which is applied in the field of double ammonia oxidation method desulfurization technology and devices, can solve the problems of being unsuitable for a large amount of flue gas, a large amount of ammonia escaping from an outlet flue gas, and a reduction in absorption efficiency, so as to improve the equipment. The effect of utilization rate, increasing economic benefits and reducing desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A hydrogen peroxide desulfurization process, comprising the following steps:

[0051] (1) Preparation of desulfurizing agent ammonia water, ammonia water is prepared from liquid ammonia through an ammonia water preparation device, the mass fraction of the prepared ammonia water is 20%, stored in the ammonia water storage tank, and pumped into the bottom circulation pipeline of the absorption tower by a circulation pump when in use;

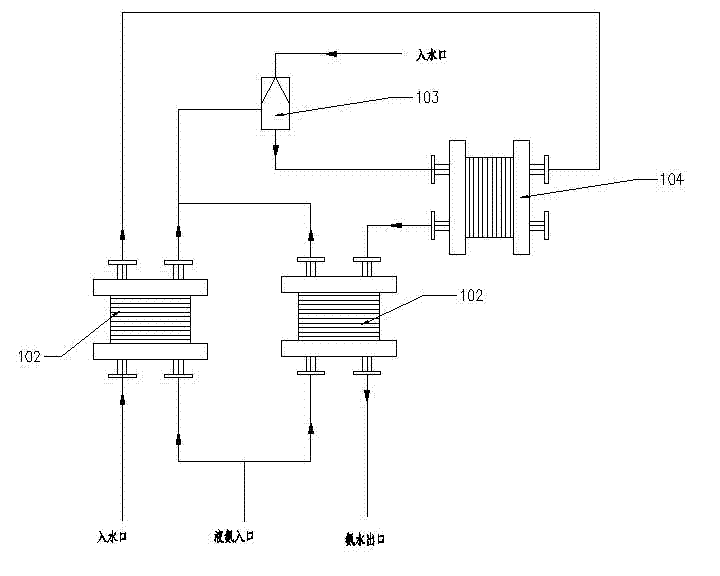

[0052] The ammonia water preparation process is as follows: liquid ammonia enters two liquid ammonia gasification heat exchange devices respectively, and the ammonia water gasifies into an endothermic reaction, which can cool down the circulating water that is fed in, and at the same time cool down the ammonia water to be discharged, and the gasified The ammonia water gas mixture enters the spray ammonia water absorption device, mixes the circulating water and the preparation water to prepare ammonia water with a mass concentration of 20%, a...

Embodiment 2

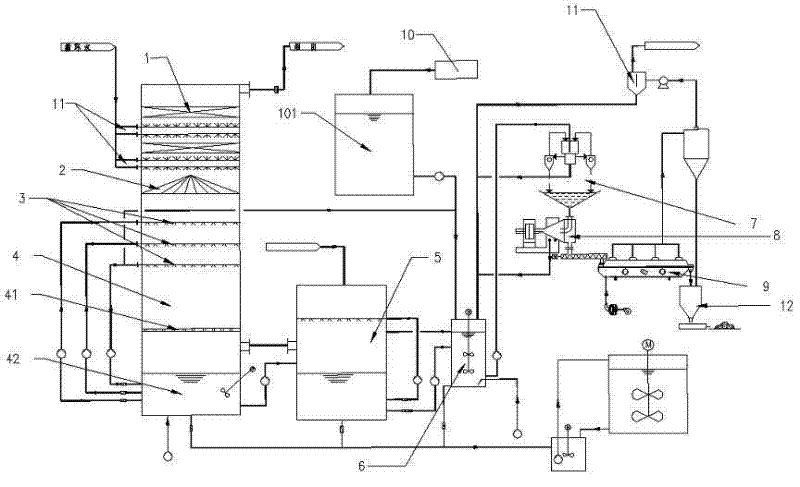

[0064] Such as figure 1 and figure 2 Shown, a kind of hydrogen peroxidation method desulfurization device comprises ammonia water preparation device 10, absorption tower 4, pre-washing tower 5, buffer oxidation box 6, cyclone 7, centrifuge 8, drying bed 9, tail gas scrubber 11, Packaging machine 12, ammonia storage tank 101; described absorption tower 4 is provided with demister 1, rotary plate convection ammonia absorption device 2, spray layer 3 and 1 / 2 perforated plate 41 sequentially from top to bottom, described The bottom of the absorption tower 4 is a slurry pool 42; the ammonia water preparation device 10 is connected with the ammonia water storage tank 101, and the ammonia water storage tank 101 is connected with the buffer oxidation tank 6, and the described pre-washing tower 5 is connected with the bottom of the absorption tower 4 , the top of the absorption tower 4 is connected with the chimney; the pre-wash tower 5 is connected with the buffer oxidation tank 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com