Process for desulphurizing and dedusting catalytic cracking regenerated smoke

A technology for desulfurization, dust removal, and flue gas regeneration, which is applied in chemical instruments and methods, dispersed particle separation, and separation methods to achieve the effects of high utilization rate, improved purity, and reduced desulfurization costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

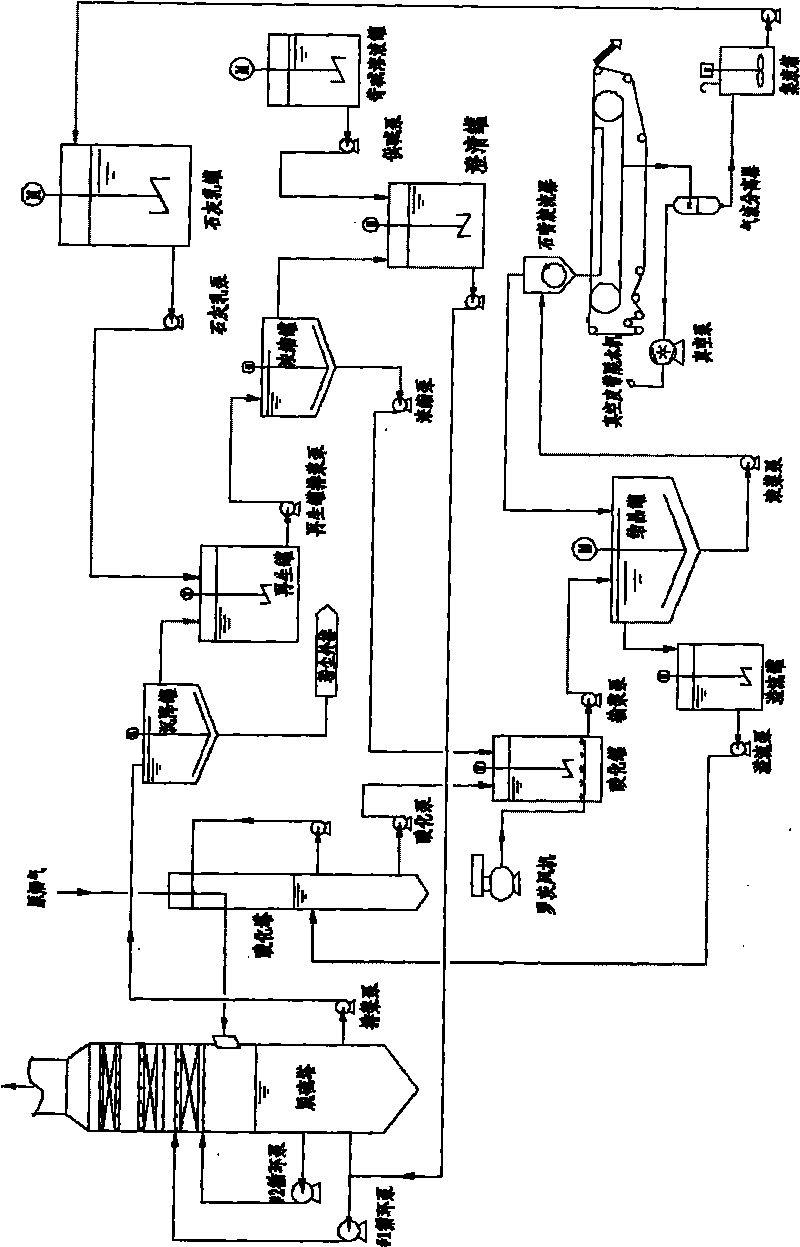

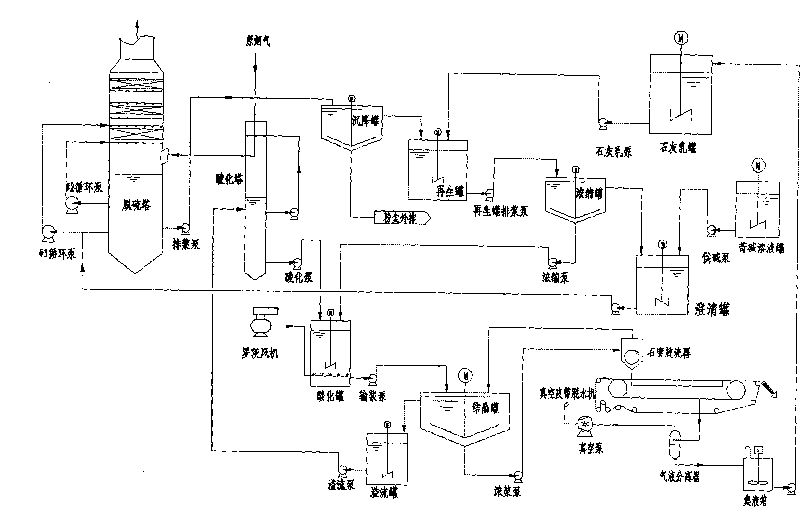

[0024] The present invention is a new process for desulfurization and dust removal of catalytic cracking flue gas. According to the principle of aerodynamics, sodium lye is used to desulfurize and dedust the flue gas, so that the lye and the flue gas are fully contacted to realize high-efficiency desulfurization and dust removal. After the desulfurization slurry is precipitated, the lime emulsion is used for sodium-alkali regeneration to obtain high-purity and high-concentration sodium alkali solution, which is injected into the desulfurization tower for effective recycling, greatly reducing costs; and the regenerated CaSO 3 Solid precipitation is acidified, oxidized, dehydrated and other processes to obtain solid gypsum with high purity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com