Method for using magnesium compound and ammonia to circulate regeneration flue gas desulfurization

A technology of magnesium compound and regenerated flue gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve full utilization and reduce desulfurization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

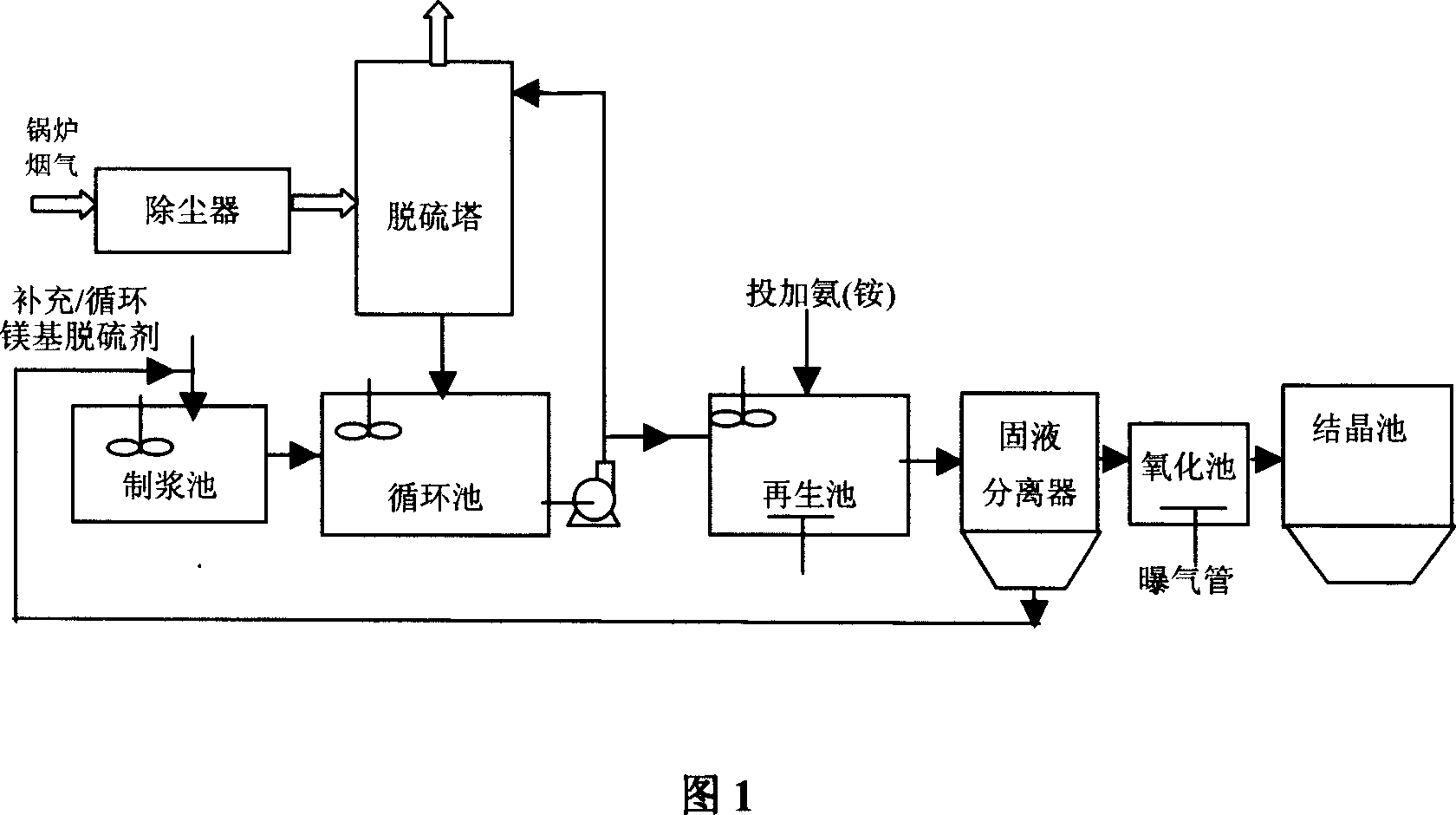

Image

Examples

Embodiment 1

[0043] Take 10kg of 200 mesh magnesium oxide powder and place it in the slurry tank, add 200L of water, and stir to prepare a magnesium hydroxide slurry with a solid content of about 6%; take 100L of the above slurry and place it in the circulating tank as a desulfurization solution. In order to prevent the precipitation of magnesium hydroxide, the slurry is continuously stirred with a mixer. A slurry pump is used to transport the desulfurization circulating liquid to the top of the desulfurization tower at a flow rate of 300L / h, and a large-aperture nozzle is used to disperse the liquid into droplets. The desulfurization tower uses an empty tower with a diameter of 200m and a height of 2000mm. The simulated flue gas enters from the bottom of the desulfurization tower and contacts the desulfurization droplets sprayed from the top of the tower in the reverse direction during the ascent. The flow of simulated flue gas is 150m 3 / h, the initial concentration of sulfur dioxide in the ...

Embodiment 2

[0047] Take 20kg of 200-300 mesh magnesium hydroxide powder, add 200L of water to the slurry tank, and stir with a stirrer to make a magnesium hydroxide slurry with a content of about 10%; take 100L of the above slurry and place it in the circulating tank as the desulfurization liquid . A slurry pump is used to transport the desulfurization circulating liquid to the blind plate of the absorption plate of the cyclone plate desulfurization tower at a flow rate of 200L / h. The diameter of the swirl plate tower is still 200m, the height is 2000mm, and two absorption plates and one demister plate are installed inside. The simulated flue gas enters from the bottom of the desulfurization tower, passes through the swirl plate for gas-liquid contact mass transfer, and absorbs sulfur dioxide in the flue gas. The flow of simulated flue gas is 200m 3 / h, the initial concentration of sulfur dioxide in the flue gas is 2000ppm, and the liquid-to-gas ratio is 1L / m 3 . When the flue gas flows out f...

Embodiment 3

[0051] The pulping and sulfur dioxide absorption conditions are the same as in Example 1, but solid ammonium bicarbonate is used instead of ammonia during regeneration. By adding ammonium bicarbonate to the oxidized desulfurization solution, the pH value is adjusted to about 7.5, so that the magnesium sulfate in the desulfurization solution is precipitated in the form of magnesium carbonate. After solid-liquid separation, the solid magnesium carbonate is returned to the pulping tank for recycling. The ammonium sulfate solution is sent to the mother liquor concentration tank, and the ammonium sulfate fertilizer is obtained through processes such as concentration, cooling and crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com