Wear-resistant high-vanadium-nitrogen high-speed steel section steel roll and manufacturing method thereof

A high-vanadium-nitrogen high-speed steel and a manufacturing method technology, applied in the field of steel rolling, can solve problems such as low hardness and poor wear resistance, and achieve the effects of improving strength and toughness, reducing production costs, and promoting the refinement of solidification structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

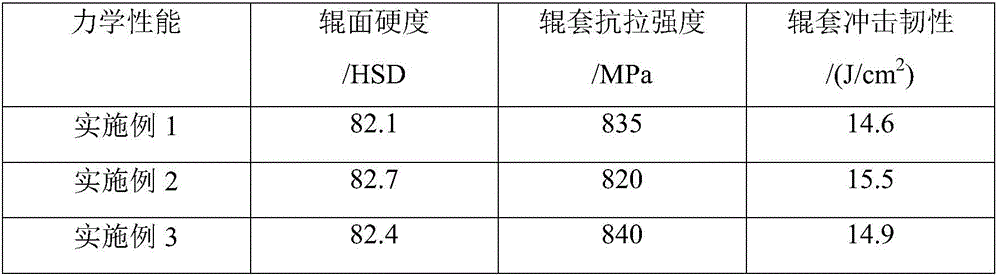

Examples

Embodiment 1

[0036] A wear-resistant high-vanadium-nitrogen high-speed steel profile roll with an outer diameter of φ350mm and its manufacturing method, which is formed by hot-packing a high-vanadium-nitrogen high-speed steel roll sleeve and a medium-carbon steel roll shaft, and using an electric furnace to melt the high-vanadium-nitrogen high-speed steel material, specifically The preparation process steps are:

[0037] ①M2 high-speed steel (also known as W6Mo5Cr4V2 high-speed steel) scrap with a mass fraction of 20% (the chemical composition and mass fraction of M2 high-speed steel scrap are: 0.86C, 0.29Si, 0.27Mn, 0.012S, 0.025P, 3.99Cr, 1.90V, 4.97Mo, 6.07W, 0.14Ni, 0.11Cu, the balance is Fe), 4.8% vanadium nitrogen alloy (the chemical composition and mass fraction of vanadium nitrogen alloy are: 43.91V, 8.77N, 0.042S, 0.050 P, 0.18C, balance Fe), 1.8% ferroniobium (the chemical composition and mass fraction of ferroniobium are: 55.28Nb, 0.06Ta, 0.94Al, 0.56Si, 0.017C, the balance is F...

Embodiment 2

[0043] A wear-resistant high-vanadium-nitrogen high-speed steel-shaped steel roll with an outer diameter of φ290mm and its manufacturing method, which is formed by hot-packing a high-vanadium-nitrogen high-speed steel roll sleeve and a medium-carbon steel roll shaft, and using an electric furnace to melt high-vanadium-nitrogen high-speed steel materials, specifically The preparation process steps are:

[0044]① Use M2 high-speed steel (also known as W6Mo5Cr4V2 high-speed steel) scrap with a mass fraction of 24% (the chemical composition and mass fraction of M2 high-speed steel scrap are: 0.82C, 0.44Si, 0.20Mn, 0.017S, 0.021P, 3.82Cr, 2.17V, 4.53Mo, 6.74W, 0.21Ni, 0.10Cu, the balance is Fe), 4.5% vanadium nitrogen alloy (the chemical composition and mass fraction of vanadium nitrogen alloy are: 47.22V, 8.06N, 0.038S, 0.047 P, 0.29C, balance Fe), 2.2% ferroniobium (the chemical composition and mass fraction of ferroniobium are: 55.23Nb, 0.09Ta, 1.28Al, 0.75Si, 0.016C, the balanc...

Embodiment 3

[0050] A wear-resistant high-vanadium-nitrogen high-speed steel-shaped steel roll with an outer diameter of φ320mm and a manufacturing method thereof. It is made of high-vanadium-nitrogen high-speed steel roll sleeves and medium-carbon steel roll shafts by thermal charging and compounding. The high-vanadium-nitrogen high-speed steel material is smelted in an electric furnace, specifically The preparation process steps are:

[0051] ① Use M2 high-speed steel (also known as W6Mo5Cr4V2 high-speed steel) scrap with a mass fraction of 22% (the chemical composition and mass fraction of M2 high-speed steel scrap are: 0.87C, 0.35Si, 0.17Mn, 0.021S, 0.020P, 4.24Cr, 1.63V, 4.67Mo, 5.65W, 0.12Ni, 0.22Cu, the balance is Fe), 4.6% vanadium nitrogen alloy (the chemical composition and mass fraction of vanadium nitrogen alloy are: 43.19V, 9.47N, 0.038S, 0.045 P, 0.30C, balance Fe), 2.0% ferroniobium (the chemical composition and mass fraction of ferroniobium are: 55.27Nb, 0.13Ta, 1.18Al, 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com