Multidirectional forging method for high-alloyed high-temperature alloy sheared billet/biscuit

A multi-directional forging and superalloy technology, which is applied in the field of multi-directional forging of high-alloyed superalloy billets/cakes, can solve the problems of many deformation dead zones, restricting large-scale engineering applications, and long process routes. Guaranteed uniformity and consistency, easy industrial production, low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

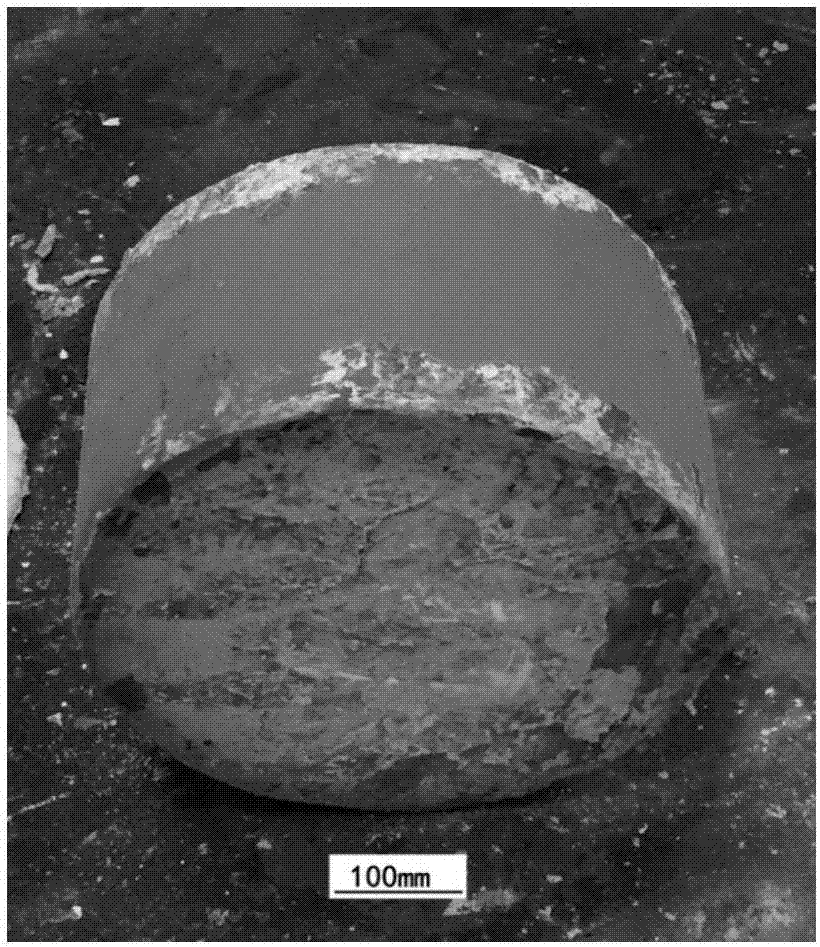

[0050] The preparation size is The average grain size is ASTM grade 8-9 high-alloyed nickel-based alloy turbine disc cake blank forgings.

[0051] Nickel-based turbine disc alloy, its chemical composition is: C: 0.03wt%, Co: 13wt%, Cr: 16wt%, W: 4.2wt%, Mo: 3.9wt%, Ti: 3.7wt%, Al: 2.1wt% , B: 0.015wt%, Zr: 0.05wt%, Nb: 0.7wt%, Ta: 0%, Fe: ≤0.5wt%, and the balance is Ni and unavoidable impurities.

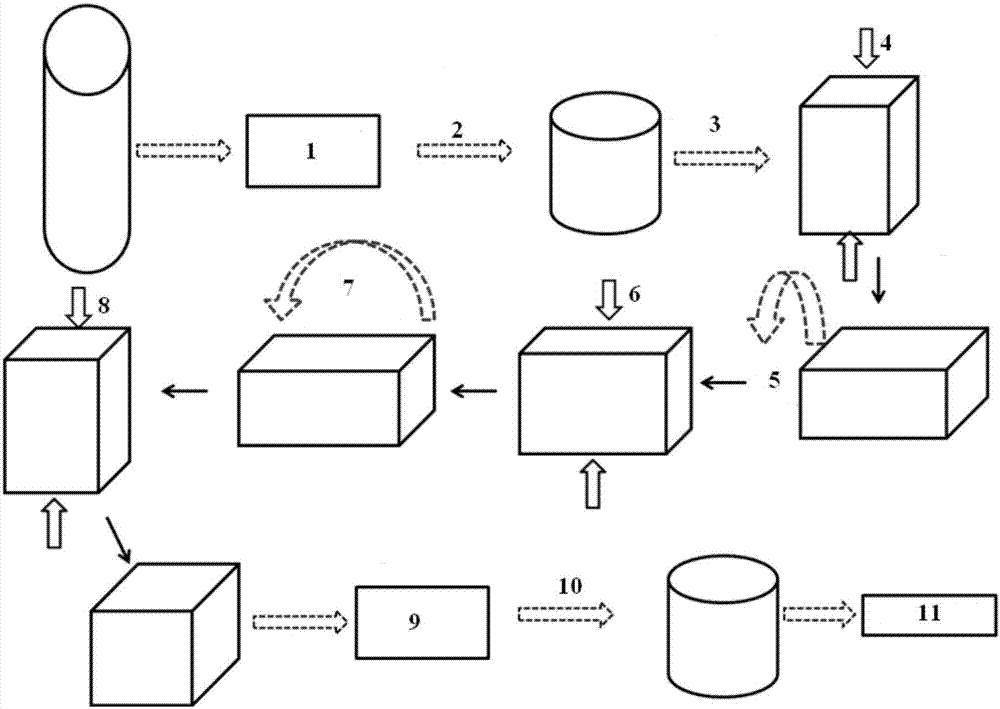

[0052] Such as figure 1 It is a specific flow chart of the multi-directional forging method of the present invention. The multi-directional forging method of the cake blank forging in embodiment 1 adopts the electroslag remelting continuous directional solidification technology (ESR-CDS) to prepare a directional solidified solidified iron with a diameter of 270 mm and a length of 1150 mm. Ingot casting mainly includes the following steps:

[0053] 1) The high-temperature homogenization treatment of low-segregation, high-purity directional solidification ingots must have four ste...

Embodiment 2

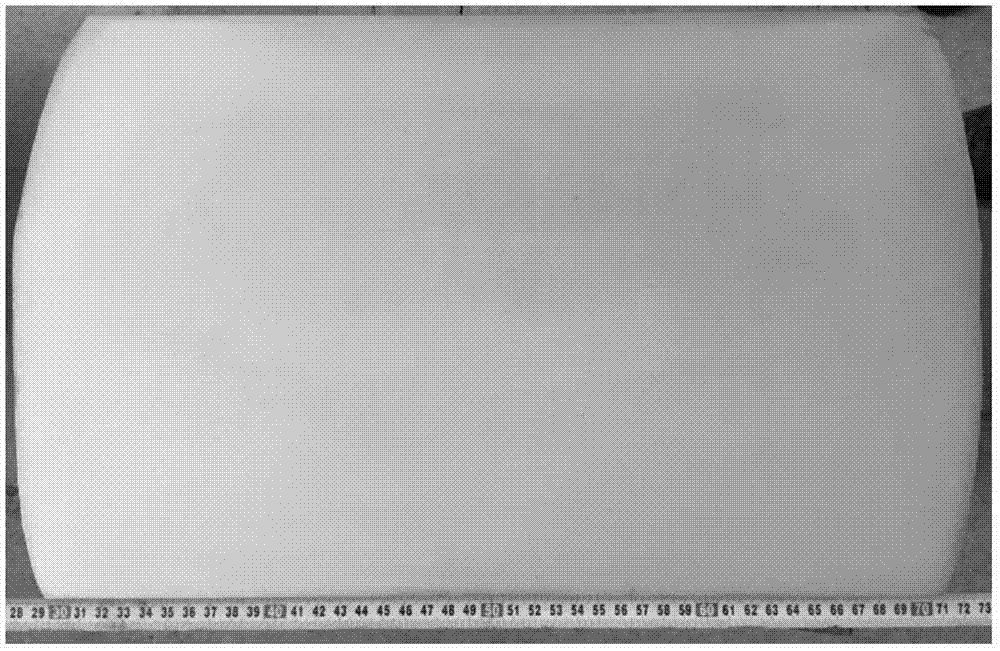

[0064] The preparation size is The average grain size of ASTM9-10 grade nickel-based turbine disk alloy rod stock forgings.

[0065] Nickel-based turbine disc alloy, its chemical composition is: C: 0.03wt%, Co: 20.5wt%, Cr: 13wt%, W: 2.1wt%, Mo: 3.8wt%, Ti: 3.7wt%, Al: 3.4wt% %, B: 0.015wt%, Zr: 0.05wt%, Nb: 0.9wt%, Ta: 2.4wt%, Fe: ≤0.5%, and the balance is Ni and unavoidable impurities.

[0066] The multidirectional forging method of the billet forging of embodiment 2 adopts the continuous directional solidification technology of electroslag remelting to prepare a diameter of 270mm, and a length of a directional solidified ingot of 1200mm mainly includes the following steps:

[0067] 1) Perform high-temperature homogenization treatment on the low-segregation, high-purity directional solidification ingot: there are four steps in the heating stage, the first step temperature is 400 °C for 2 hours, the second step temperature is 950 °C for 2 hours, and the second step temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com