Wet mixture mortar capable of pumping

A wet-mixed mortar and pumping technology, used in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of long use time, loss of consistency, and inability to pump, and reduce the labor intensity of workers. , The effect of high promotion and application value and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

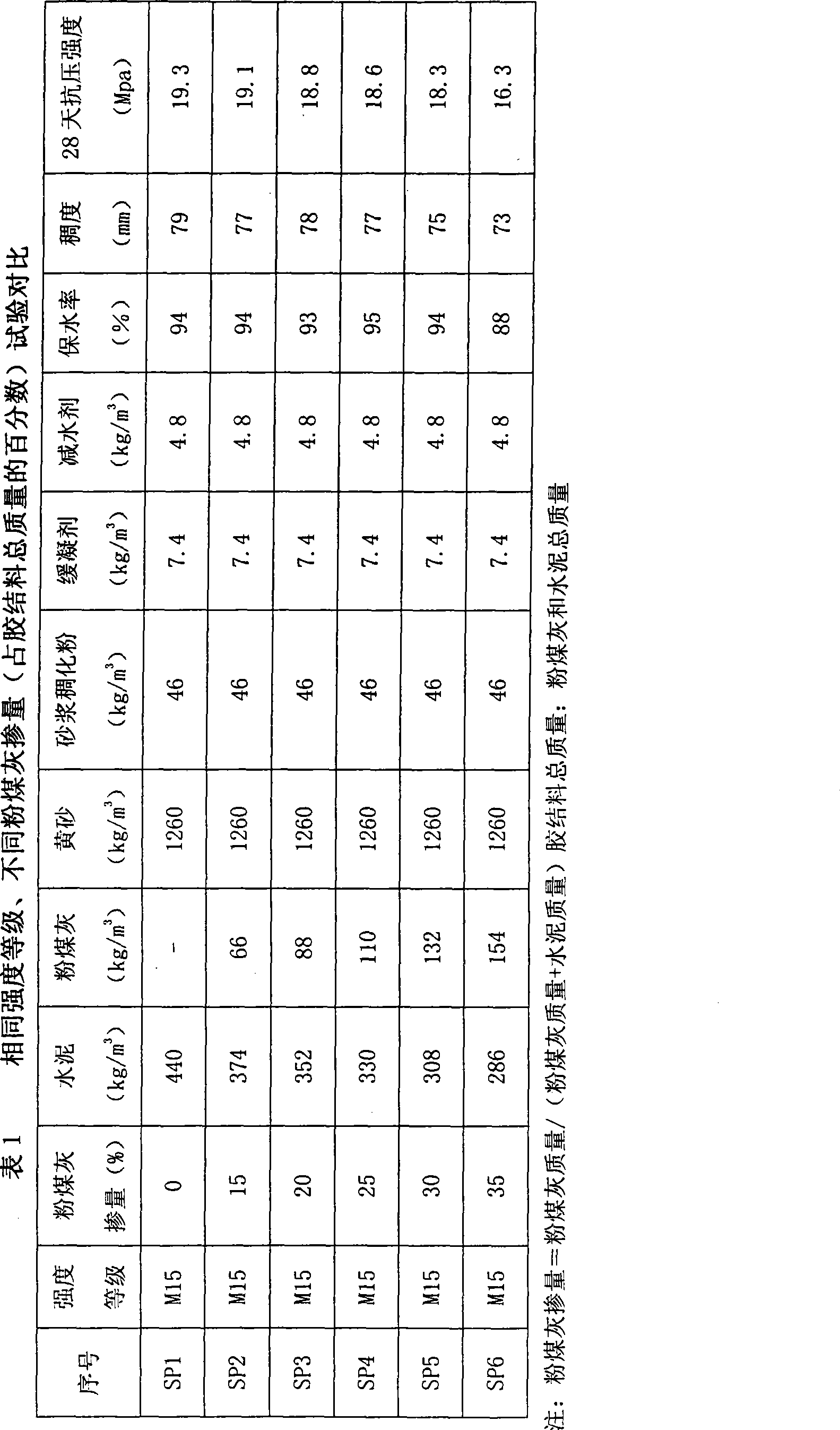

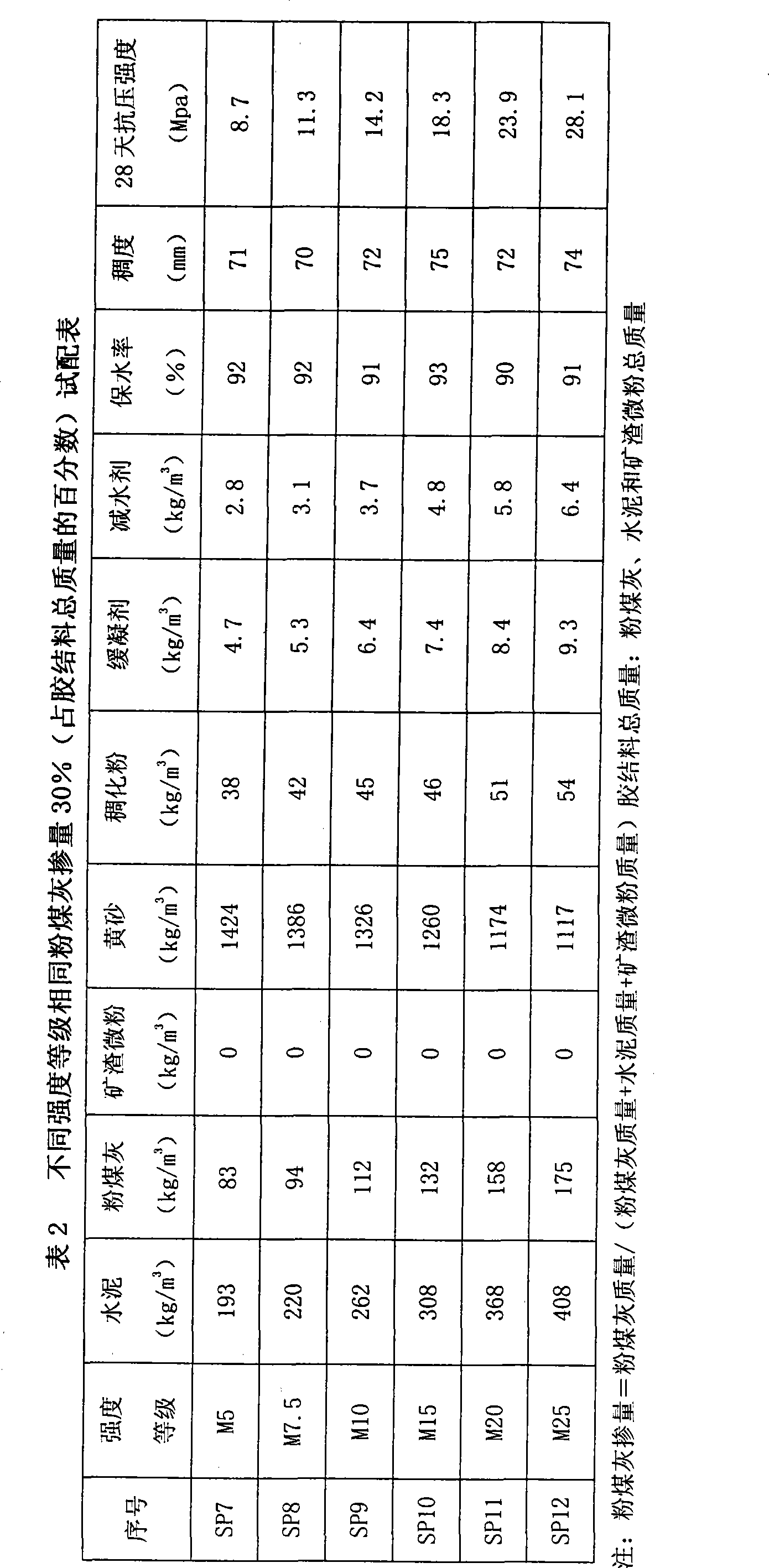

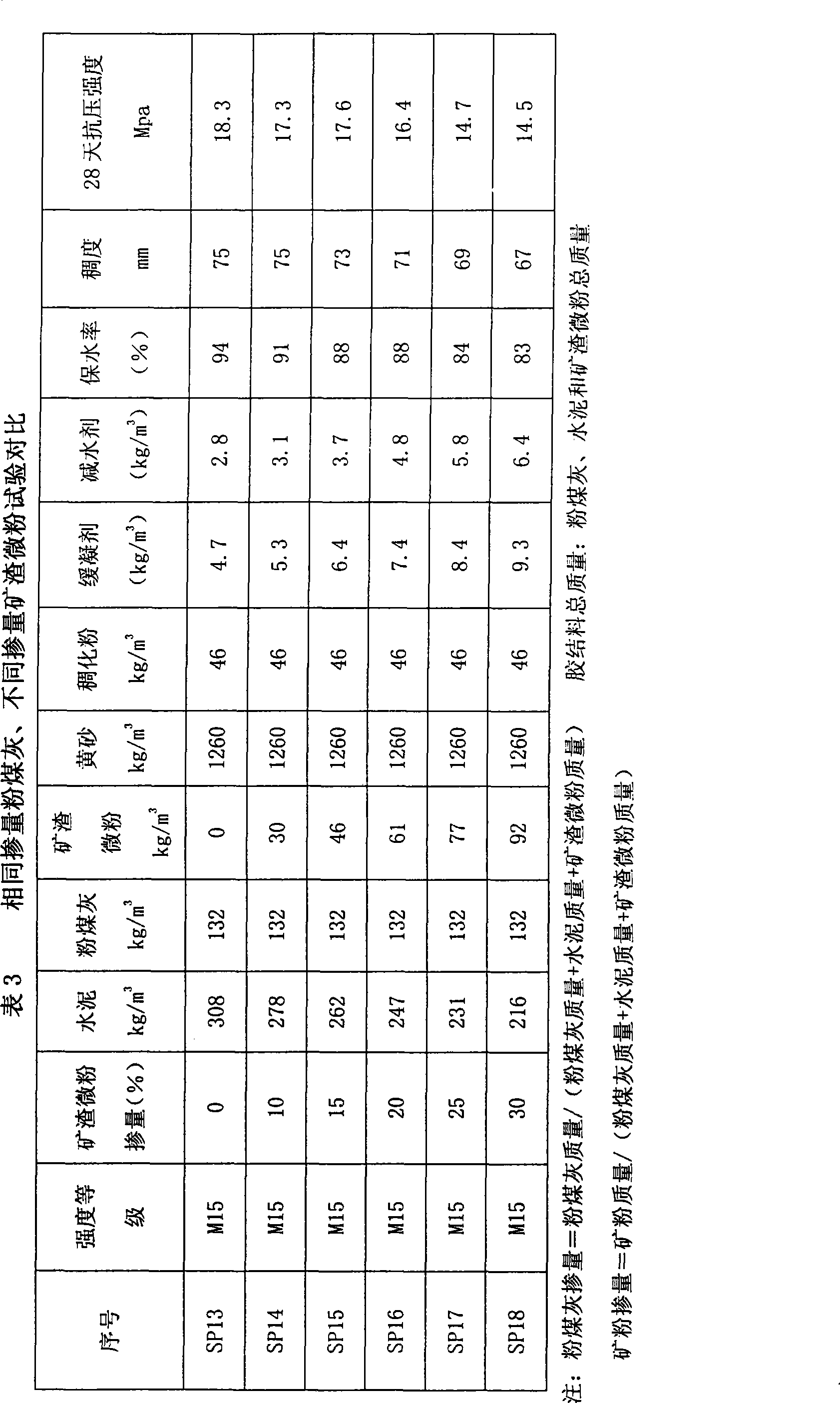

[0031] The present invention is further illustrated by the following examples. The embodiment adopts the medium sand in the second zone with a fineness modulus of 2.8, S95 grade slag powder and II grade fly ash, the retarder is lignosulfonate, and the water reducer is naphthalenesulfonic acid high-efficiency water reducer. Cellulose ether is methyl cellulose ether. Weigh various raw materials in proportion and mix evenly, add 250Kg-300Kg of water and stir evenly.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com