Power-driven lift platform carrier vehicle for steel mill

A transport vehicle and power technology, applied in the direction of transportation and packaging, parallel-carrying vehicles, vehicle parts, etc., can solve the problems of high performance requirements, destructive damage to the whole vehicle, low transportation efficiency, etc., and reduce the amount of data communication , reduce the failure rate, improve the reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] According to the attached Figure 1-9 To specifically introduce several basic operation embodiments of the present invention.

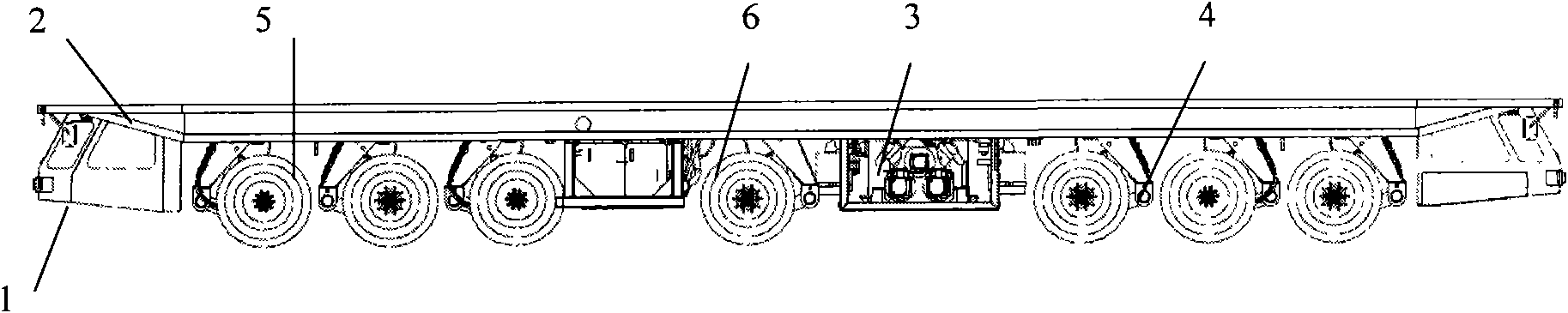

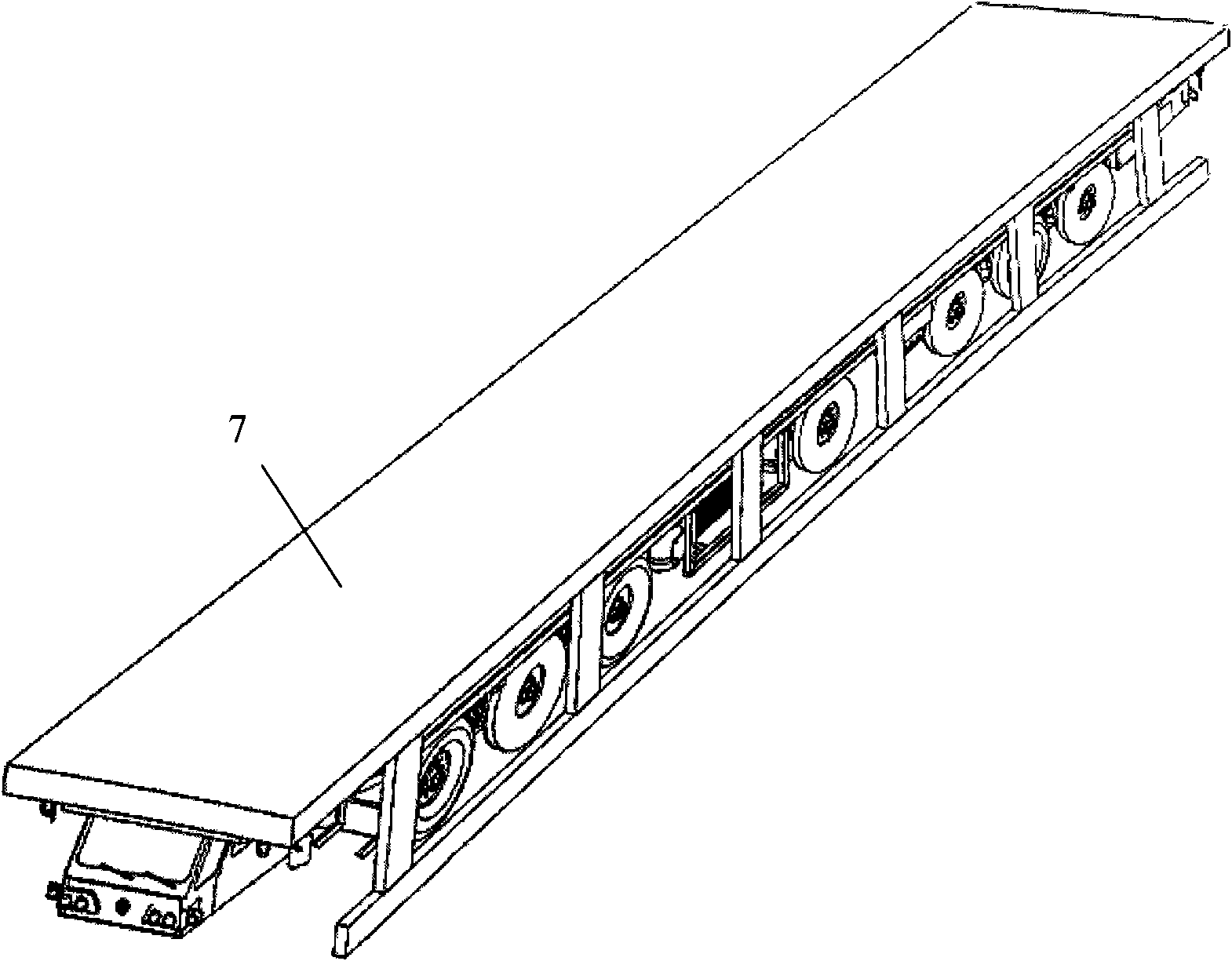

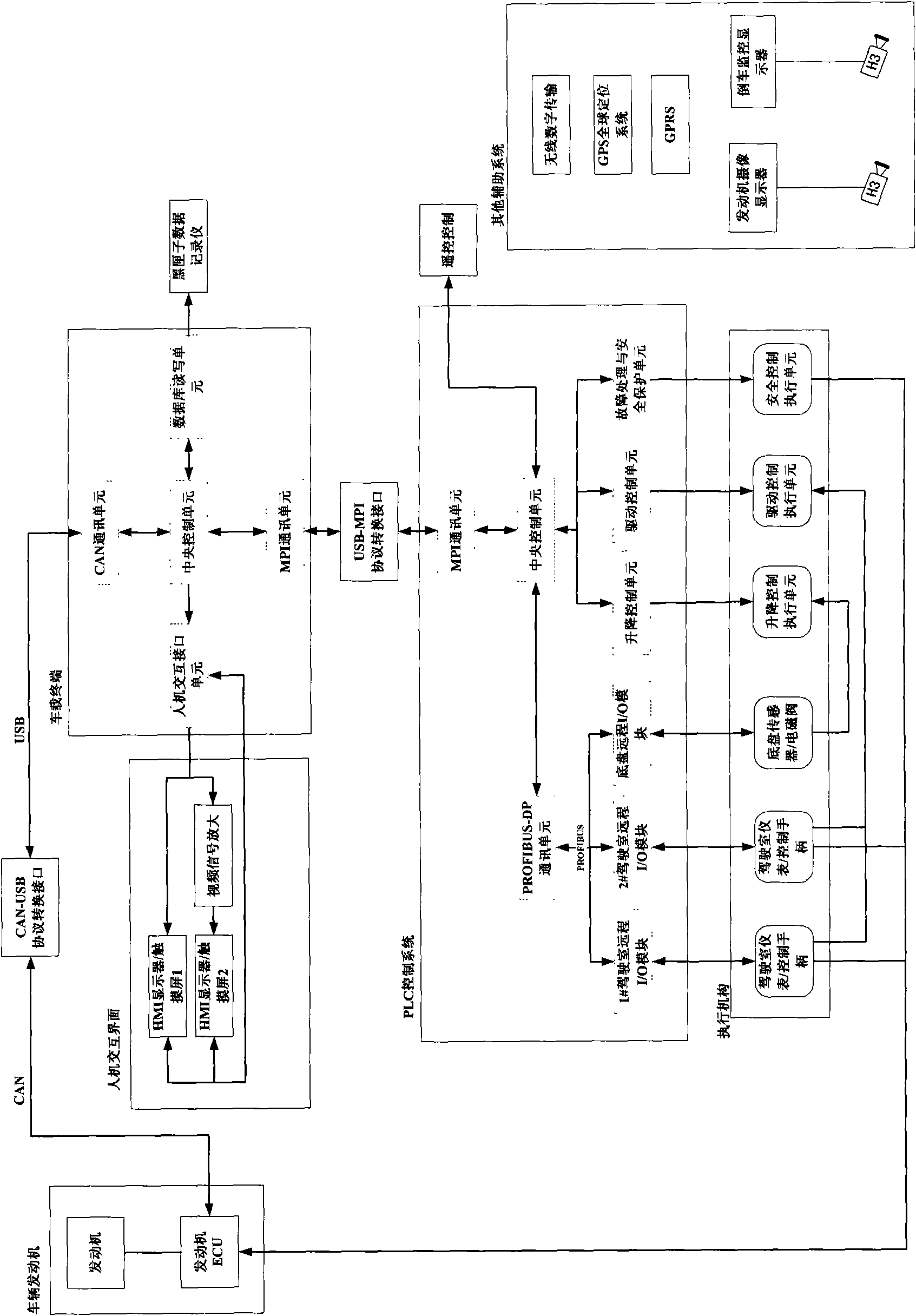

[0076] Such as figure 1 As shown, a power lifting flat frame double-headed transport vehicle for steel mills shown in the present invention adopts a 7-axis full steering design. Its running mechanism 4 is composed of 6 sets of drive axles and 8 sets of brake axles, and 14 sets of axles follow Arrange in a certain order to realize the walking function of the whole vehicle. The supporting structure includes 2 groups of fixed supporting structures 6 and 12 groups of rotating supporting structures 5. All of the rotating supporting structures 5 can realize independent steering; the frame 2 is supported by the rotating supporting structure 5 and the fixed supporting structure 6. The lifting cylinder of the supporting structure is The vertical lifting under the action of pressure oil can realize the lifting of the frame platform. The vehicle is powered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com