Grinding equipment special for bio-pharmaceuticals

A technology of biopharmaceuticals and equipment, applied in application, grain processing, food science, etc., can solve the problems that materials are easily blocked in the feed inlet, affect the efficiency of material grinding and processing, and the materials cannot fall into the equipment, so as to improve the processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

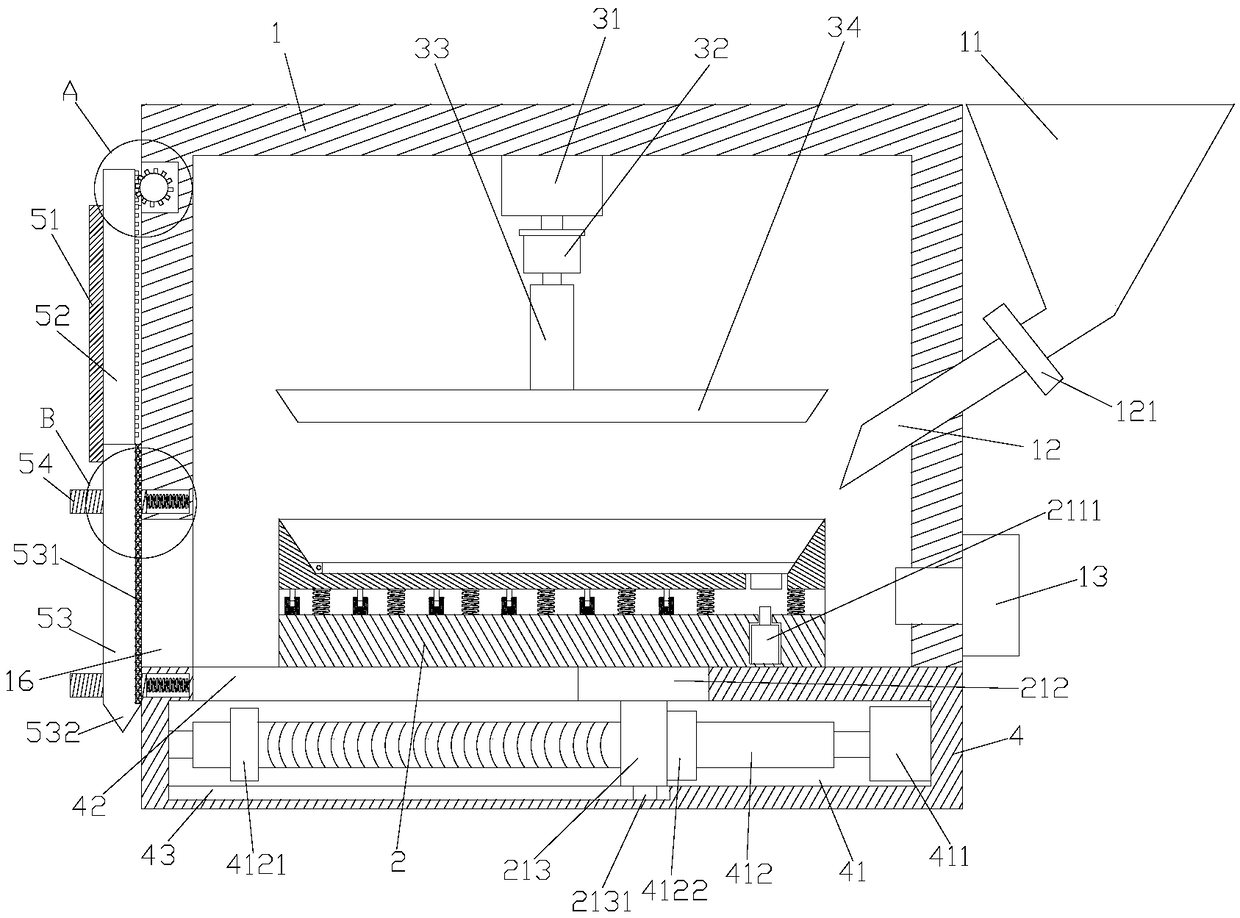

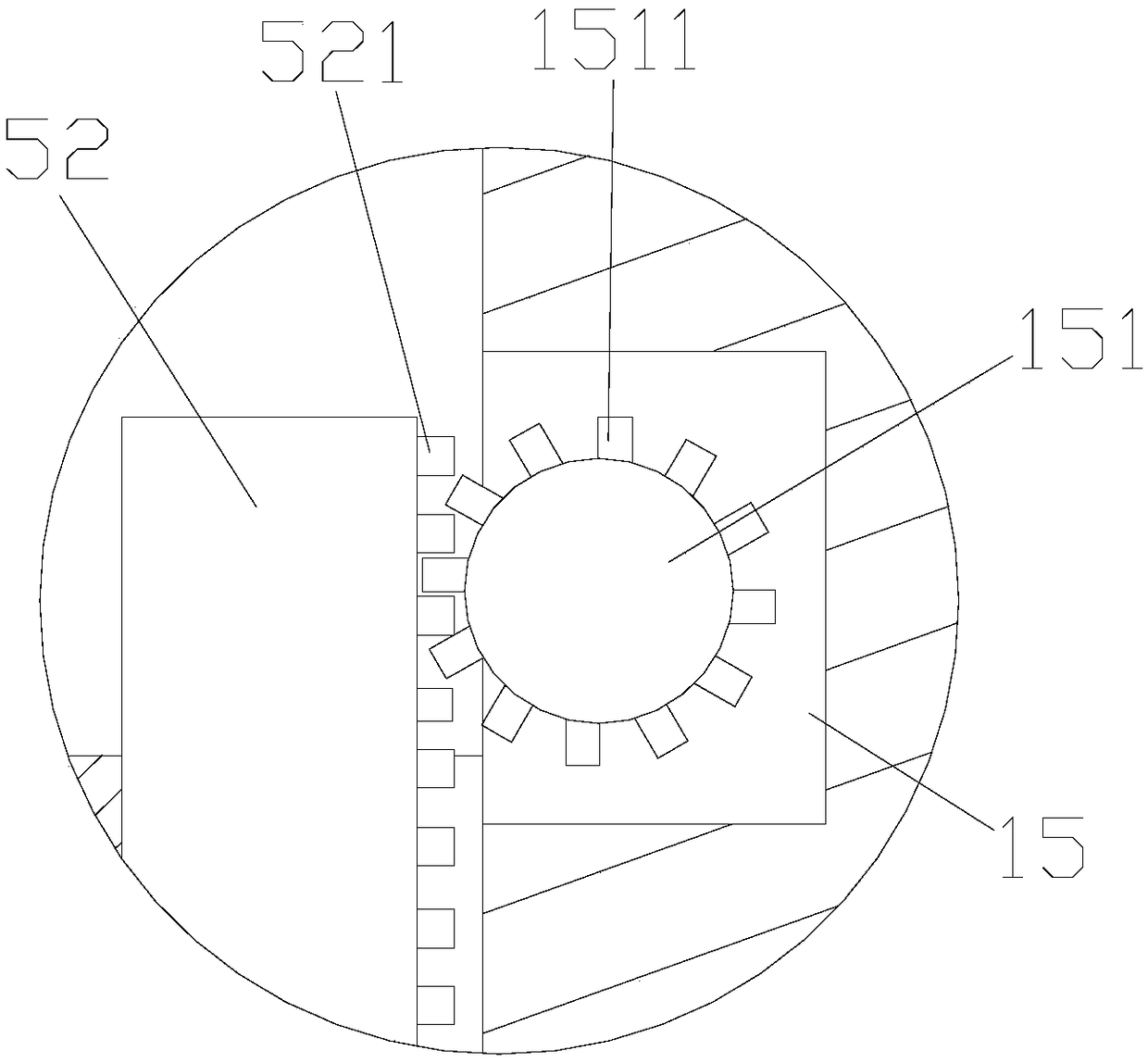

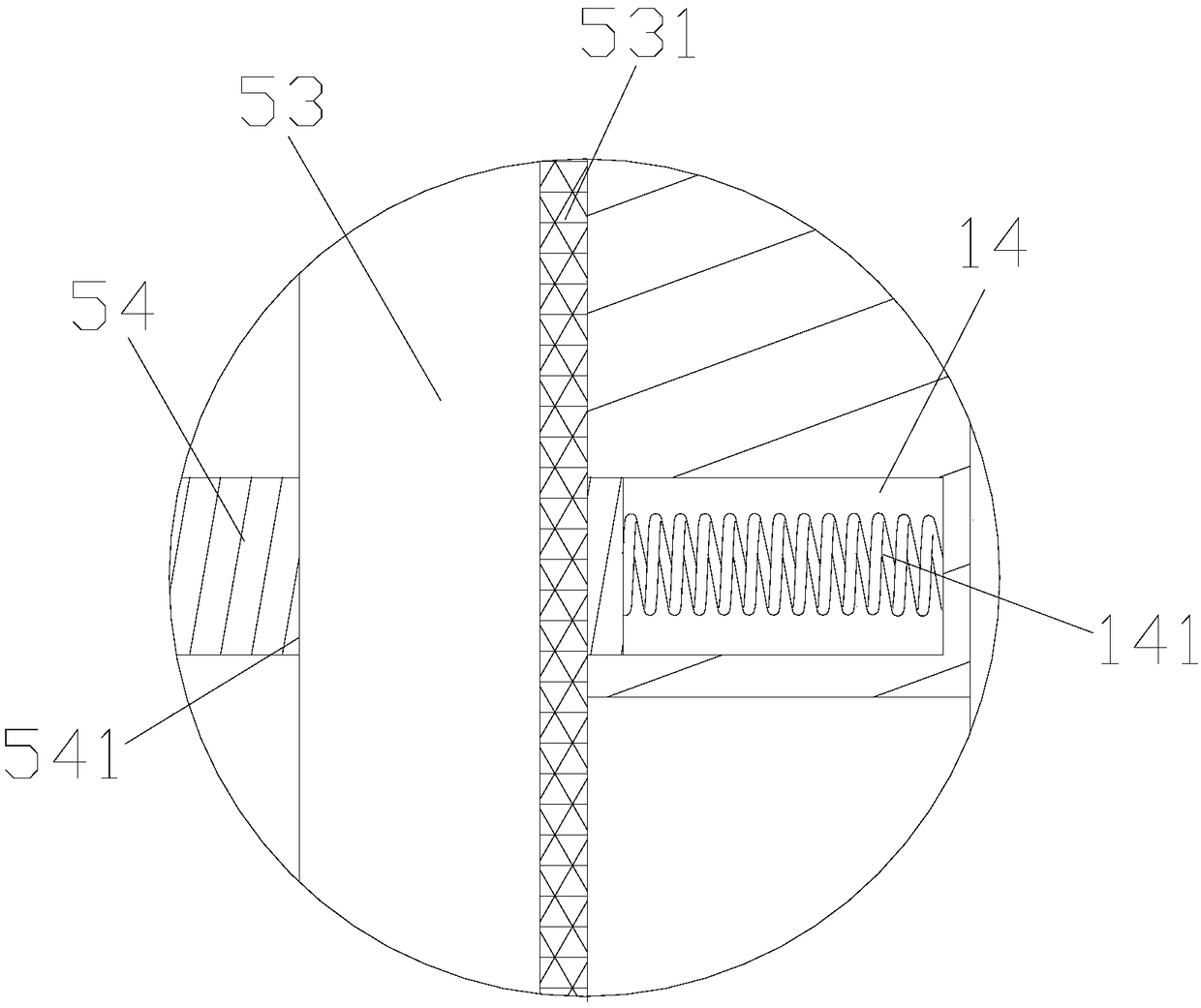

[0029] Such as Figure 1-5 As shown, a special grinding equipment for biopharmaceuticals includes a casing 1, a grinding device arranged in the casing 1 and a base 4 arranged at the bottom of the casing 1; one side of the casing 1 is provided with There is a feed port 11, the bottom of the feed port 11 is provided with a feed pipe 12 communicating with the box body 1, the feed pipe 12 is provided with a sealing valve 121, and the opening of the feed port 11 is set as a funnel Shaped structure, it is convenient to put the material into the feed port 11; the feed pipe 12 is inclined, the feed pipe 12 is inclined, and the outlet of the feed pipe 12 is opposite to the grinding device. When the material enters the box from the feed port 11 When inside the body 1, the material falls down along the feeding port 11 and the feeding pipe 12 through the action of gravity, and through the inclined setting of the feeding pipe 12, the material falls on the grinding device under the action o...

Embodiment 2

[0040] Such as Figure 6-8As shown, the difference between this embodiment and Embodiment 1 is that: the support block 21 is provided with an unloading device for shaking the bottom plate 223, and the unloading device can drive one side of the bottom plate 223 to rise After the material finishes the grinding process in the casing 1, the unloading device starts to make one side of the bottom plate 223 rise, and the bottom plate 223 side rises to make the bottom plate 223 form an inclined plane, so that the material on the bottom plate 223 is formed along the bottom plate 223 The inclined surface rolls down from the bottom plate 223 to facilitate the collection of the ground materials; when the unloading device is raised on the side of the driving bottom plate 223, the unloading device controls the bottom plate 223 to vibrate, so that the bottom plate 223 is accompanied by the formation of the inclined surface. Shaking effect, the materials on the bottom plate 223 are shaken off...

Embodiment 3

[0046] Such as Figure 9-12 As shown, the difference between this embodiment and Embodiment 1 is that a vibrating assembly is provided in the feed port 11, and a feeding assembly is provided in the feed pipe 12; when the material is placed in the feed port 11, the material When entering the box 1, the entry of the material causes the vibrating component to vibrate, and the vibrating component shakes the material off to prevent the material from adhering to the inner wall of the feed port 11 and affecting the material entering the box 1; through the vibrating component, the material Vibration is generated in the feed port 11, so that the material generates a gap in the vibration, which better helps the material fall from the feed port 11, and avoids the blockage of the feed port 11 caused by too much material entering the feed port 11; The setting of the feed assembly in the feed pipe 12 makes the material falling on the feed pipe 12 move along the feed pipe 12 under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com