Fertilizer multi-stage crushing device for agriculture

A pulverizing device and fertilizer technology, applied in the field of agricultural machinery, can solve problems such as poor applicability, different fertilizer size and particle size, and fertilizer quality influence, and achieve the effects of improving pulverization efficiency, high screening efficiency, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

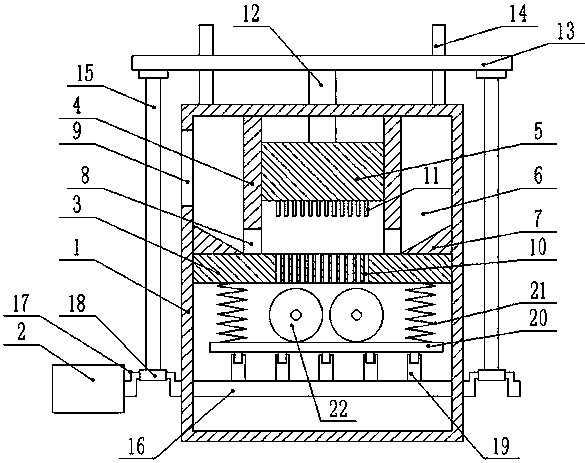

[0016] Please refer to the figure, in the embodiment of the present invention, a multi-stage crushing device for agricultural fertilizers includes a housing 1, a motor 2, a partition 3 and a crushing hammer 5; the partition 3 is horizontally fixed in the middle of the housing 1, The housing 1 is divided into upper and lower parts; a vertical guide cylinder 4 is fixed on the upper surface of the partition 3, the guide cylinder 4 is coaxially arranged with the housing 1, and the gap between the guide cylinder 4 and the housing 1 is set to Feed trough 6, can store fertilizer, the bottom of feeding trough 6 is provided with a circle of inclined material guide block 7, and the lower end of material guide block 7 faces guide cylinder 4, and the guide cylinder 4 corresponding to the lower end of material guide block 7 is provided with lower Feed port 8, so that the fertilizer in the feed tank 6 enters the guide cylinder 4 through the feed port 8, and a filler port 9 is opened on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com