Compound grinding aid for cement

A grinding aid and cement technology, applied in the field of cement manufacturing, can solve the problems of single component, poor applicability, price and quality of controlled raw materials, etc., and achieve the effect of eliminating particle agglomeration, improving grinding efficiency and optimizing synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

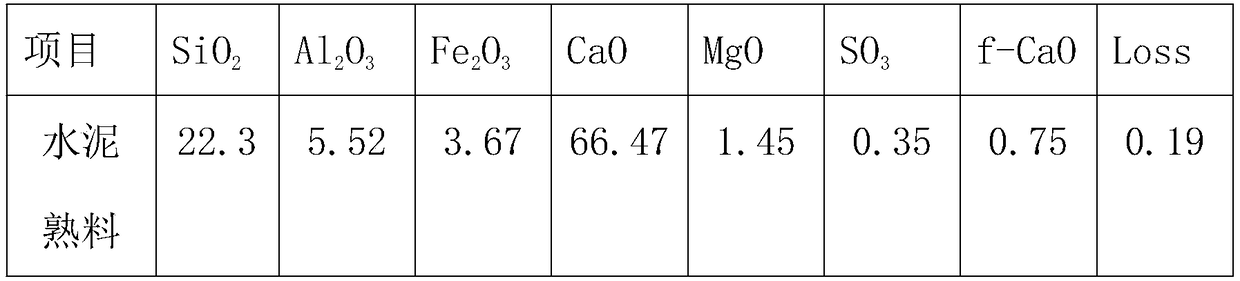

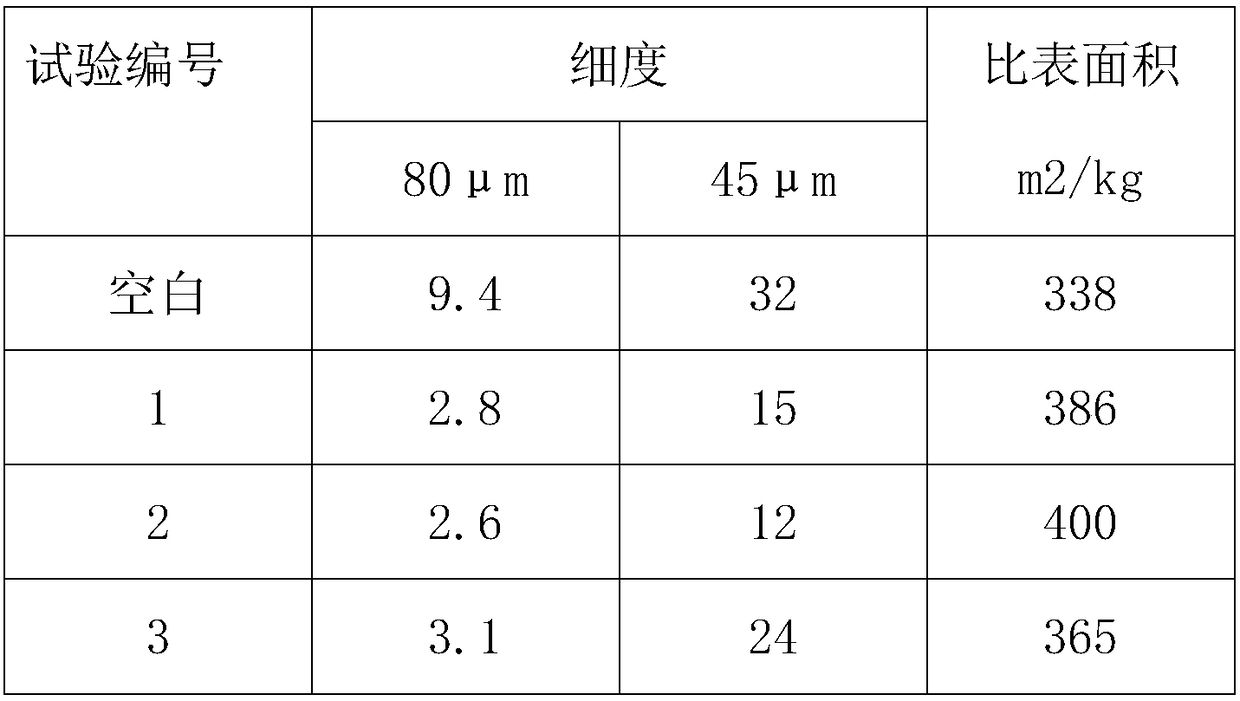

Method used

Image

Examples

Embodiment 1

[0019] A cement composite grinding aid, the cement grinding aid is composed of the following components in parts by weight: 12-28 parts of polyol amine, 12-28 parts of polyol, 6-13 parts of lignosulfonate, stearic acid 3-7 parts of sodium, 6-12 parts of molasses, 2-6 parts of sodium sulfate, 22-28 parts of water.

[0020] Further, polyol amine comprises triethanolamine, ethanolamine, triisopropanolamine, and the weight ratio of the three is: triethanolamine: ethanolamine: triisopropanolamine=(0.8-1):(0.8-1):( 0.5-1).

[0021] Further, polyhydric alcohol comprises diethylene glycol, ethylene glycol, glycerol, and the weight ratio of the three is: diethylene glycol: ethylene glycol: glycerol=(0.8-1):(0.2-0.6 ): (0.2-0.6).

[0022] Further, the lignosulfonate is a mixture of calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate, calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate The weight ratio of = (0.2-0.5): (0.8-1): (0.2-0.5).

...

Embodiment 2

[0026] A cement composite grinding aid, the cement composite grinding aid is composed of the following components in parts by weight: 12 parts of polyol amine, 12 parts of polyol, 6 parts of lignosulfonate, 3 parts of sodium stearate, molasses 6 parts, 2 parts of sodium sulfate, 22 parts of water.

[0027] Further, the polyol amine includes triethanolamine, ethanolamine, and triisopropanolamine, and the weight ratio of the three is: triethanolamine:ethanolamine:triisopropanolamine=1:0.8:0.5.

[0028] Further, the polyhydric alcohol includes diethylene glycol, ethylene glycol, and glycerol, and the weight ratio of the three is: diethylene glycol: ethylene glycol: glycerol=1:0.4:0.4.

[0029] Further, the lignosulfonate is a mixture of calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate, calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate The weight ratio of = 0.2:0.8:0.2.

Embodiment 3

[0031] A cement composite grinding aid, the cement composite grinding aid is composed of the following components in parts by weight: 22 parts of polyol amines, 22 parts of polyols, 10 parts of lignosulfonate, 5 parts of sodium stearate, molasses 9 parts, 4 parts of sodium sulfate, 25 parts of water.

[0032] Further, the polyol amine includes triethanolamine, ethanolamine, and triisopropanolamine, and the weight ratio of the three is: triethanolamine:ethanolamine:triisopropanolamine=0.8:0.9:0.7.

[0033] Further, the polyhydric alcohol includes diethylene glycol, ethylene glycol, and glycerol, and the weight ratio of the three is: diethylene glycol: ethylene glycol: glycerol=0.8:0.9:0.6.

[0034] Further, the lignosulfonate is a mixture of calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate, calcium lignosulfonate, aluminum lignosulfonate and sodium lignosulfonate The weight ratio=0.3:0.9:0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com