Water-based facing type fireproof paint and preparation method thereof

A fire retardant coating and finishing technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., to achieve the effects of good fire resistance, strong adhesion and good decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

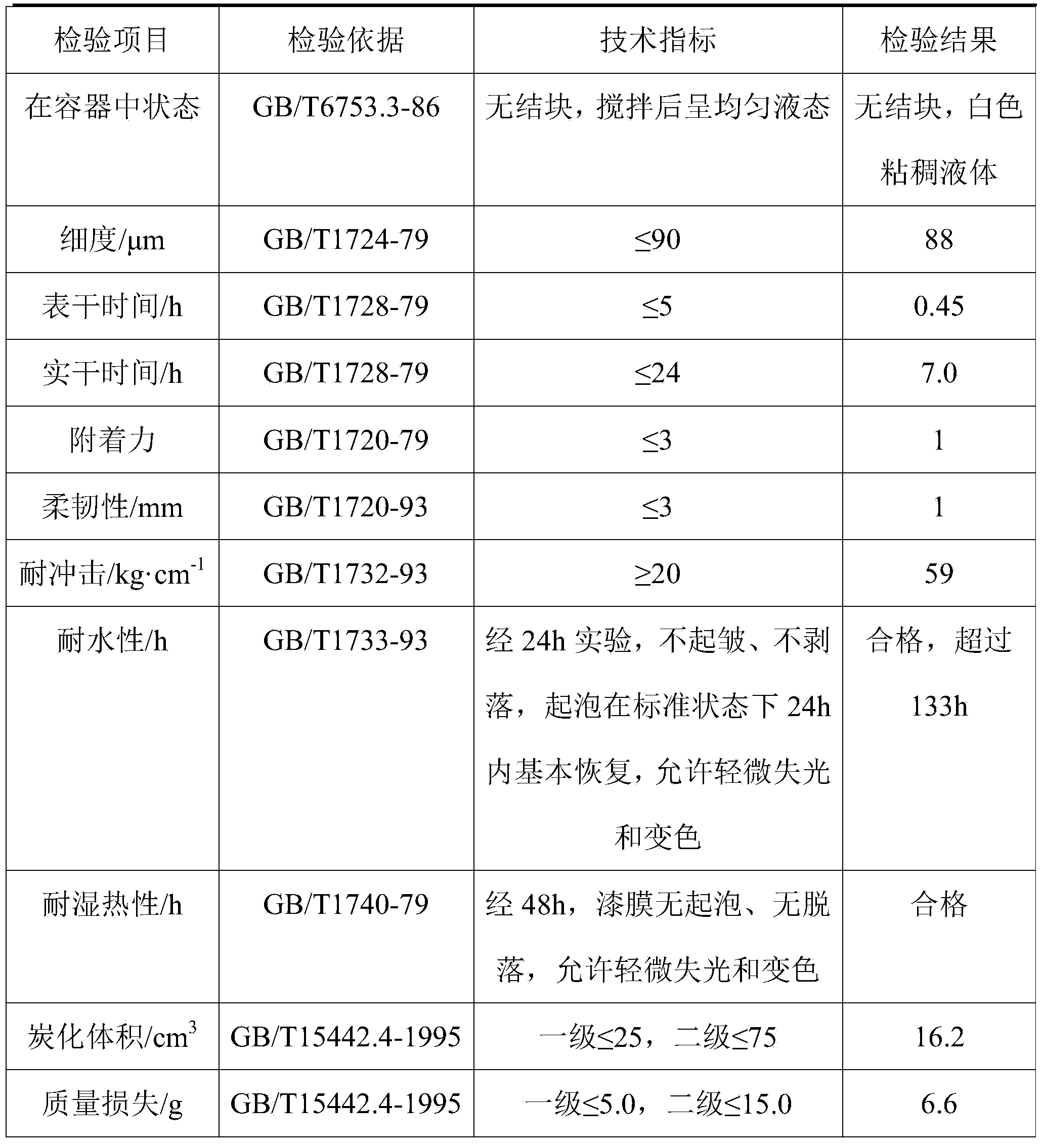

Embodiment 1

[0022] According to the water-based decorative fireproof coating of the present invention, its raw materials include by mass fraction: 19.5wt% of film formers, 23.3wt% of carbon-forming catalysts, 10.4wt% of char-forming agents, 12.6wt% of blowing agents, and 10wt% of pigments and fillers , auxiliary agent 1.0wt%, water 22.5wt%, trisodium phosphate 0.3wt%, silane defoamer 0.4wt%; Wherein, described film former is chlorine partial emulsion and modified nano-calcium carbonate / epoxy styrene-acrylic emulsion The mixture of chlorine partial emulsion and the mass ratio of modified nanometer calcium carbonate / epoxy styrene-acrylic emulsion is 0.9:1.

[0023] The water-based decorative fireproof coating of the present invention is prepared according to the following method: simultaneously adding the char-forming catalyst, char-forming agent and foaming agent into a grinder equipped with water, and then adding pigments and fillers, auxiliary agents, and trisodium phosphate in sequence ...

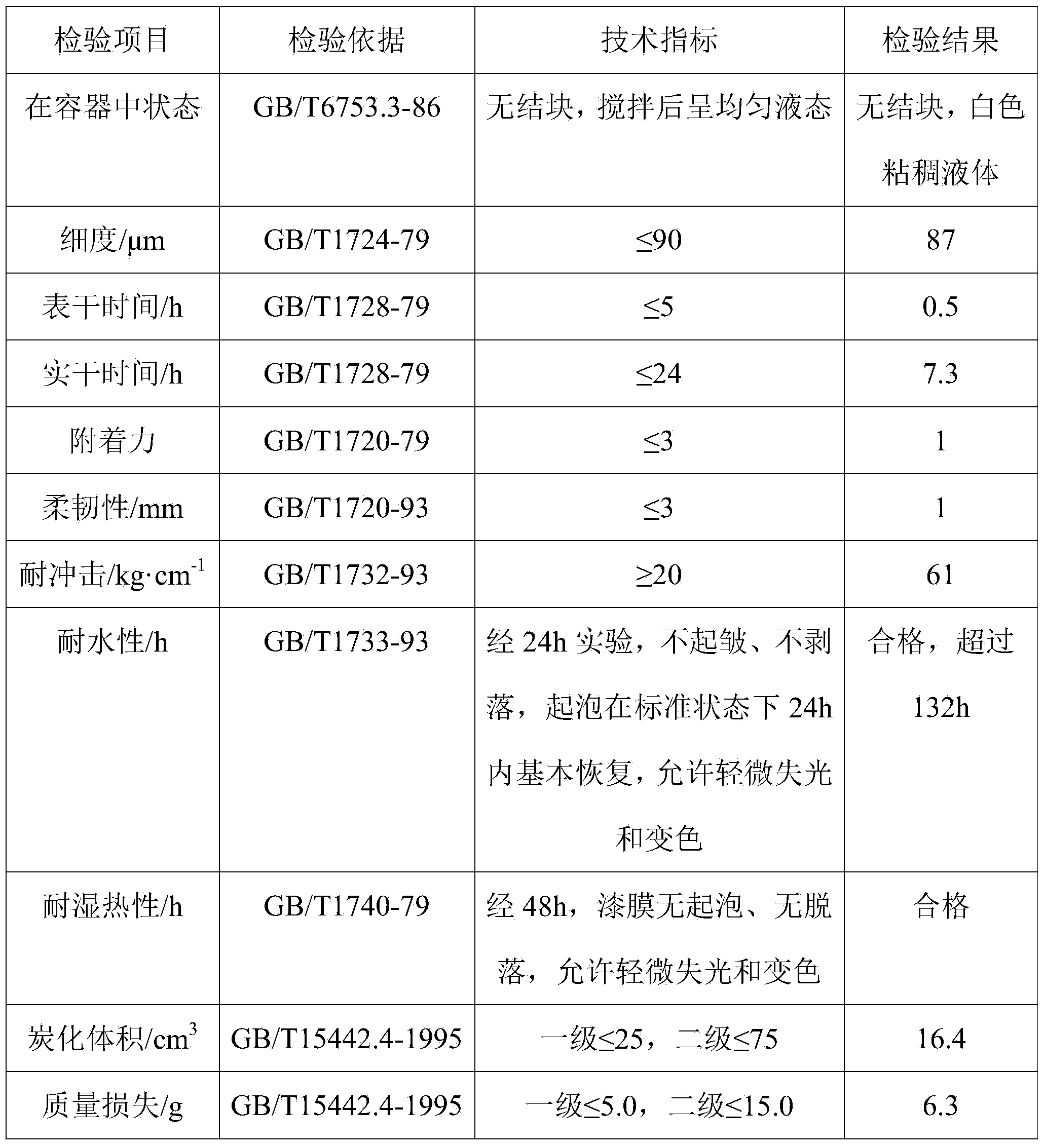

Embodiment 2

[0028] The water-based finishing type fireproof coating of the present invention, its raw material comprises by mass fraction: chlorine partial emulsion 10wt%, modified nano-calcium carbonate / epoxy styrene-acrylic emulsion 10wt%, char-forming catalyst 23.5wt%, char-forming agent 10wt% , foaming agent 12wt%, pigment and filler 11wt%, auxiliary agent 1.13wt%, water 22.37wt%;

[0029] Wherein, the modified nano-calcium carbonate / epoxy styrene-acrylic emulsion is prepared according to the following process: 1 weight part of sodium lauryl sulfate and 1 weight part of secondary octylphenol polyoxyethylene ether are added to 70 weight parts of water, stirred Raise the temperature to 45°C, heat and stir for 50 minutes, add 0.5 parts by weight of modified nano-calcium carbonate, and then add 30 parts by weight of styrene, 18 parts by weight of methyl methacrylate and 29 parts by weight of butyl acrylate dropwise at the same time, wherein the dropping time for 40 minutes, then stirred a...

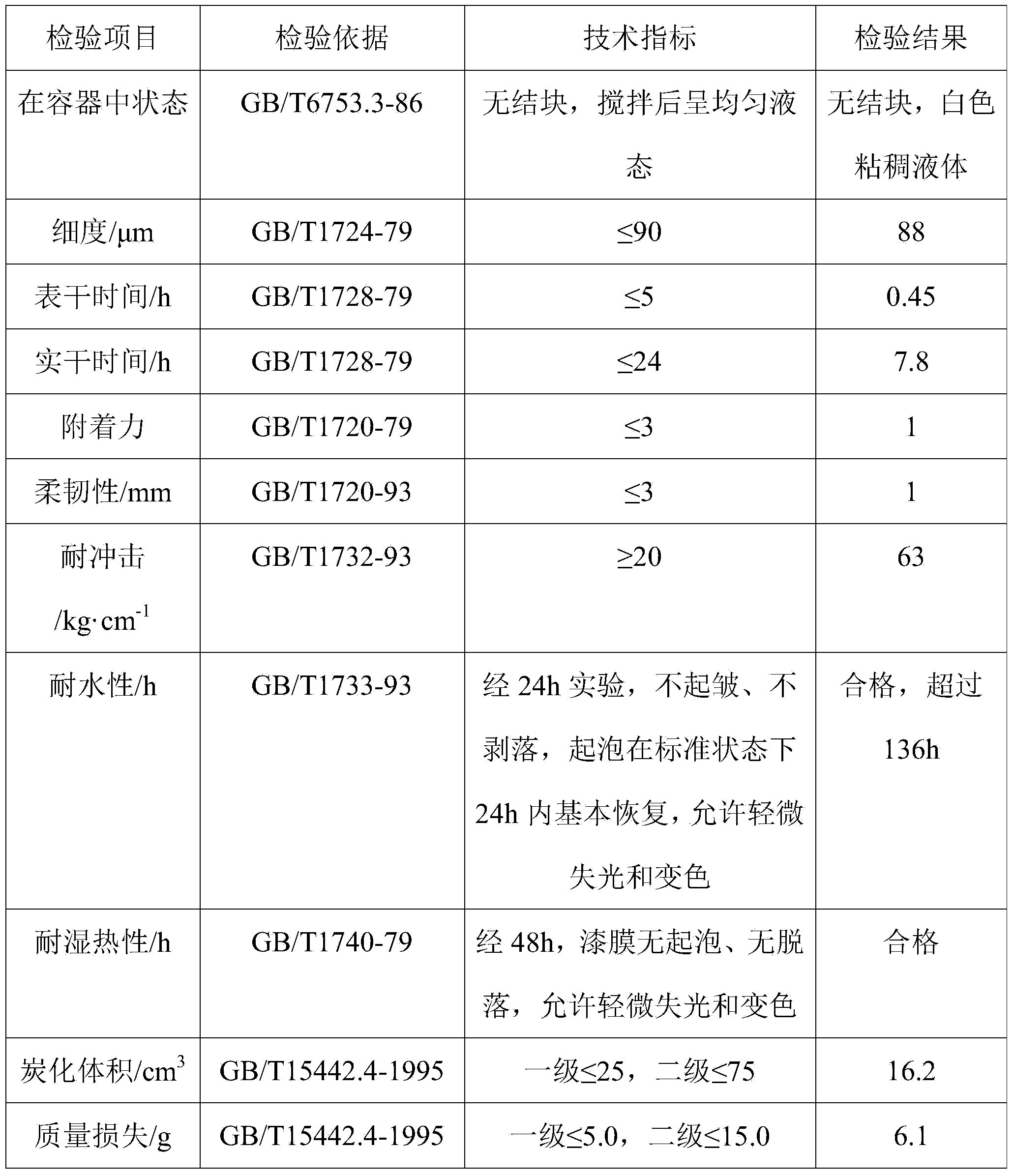

Embodiment 3

[0036] The water-based finishing type fireproof coating of the present invention, its raw material comprises by mass fraction: chlorine partial emulsion 9wt%, modified nano-calcium carbonate / epoxy styrene-acrylic emulsion 9.0wt%, ammonium dihydrogen phosphate 12.6wt%, ammonium polyphosphate 10.4wt%, sucrose 11wt%, dicyandiamide 3.6wt%, urea 5.4wt%, chlorinated paraffin 4wt%, mica powder 9wt%, thickener 0.49wt%, water 24.81wt%, trisodium phosphate 0.5wt%, Silane defoamer 0.2wt%;

[0037] The modified nano-calcium carbonate / epoxy styrene-acrylic emulsion is prepared according to the following process: add 1.5 parts by weight sodium lauryl sulfate and 0.5 parts by weight of 2-octylphenol polyoxyethylene ether in 100 parts by weight of water, stir and heat up to 55°C, keep stirring for 35 minutes, add 1.2 parts by weight of modified nano-calcium carbonate, and then drop 35 parts by weight of styrene, 15 parts by weight of methyl methacrylate and 30 parts by weight of butyl acrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com