Chinese goosebeery clear juice concentrating process

A production process and kiwifruit technology, applied in the field of concentrated kiwifruit clear juice production process, can solve the problems of difficult industrialized production, the clear juice method does not take into account technical maturity problems and cost problems, etc., to improve efficiency, eliminate pectin sedimentation, improve The effect of juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: Determination of process parameters of kiwifruit puree pectinase

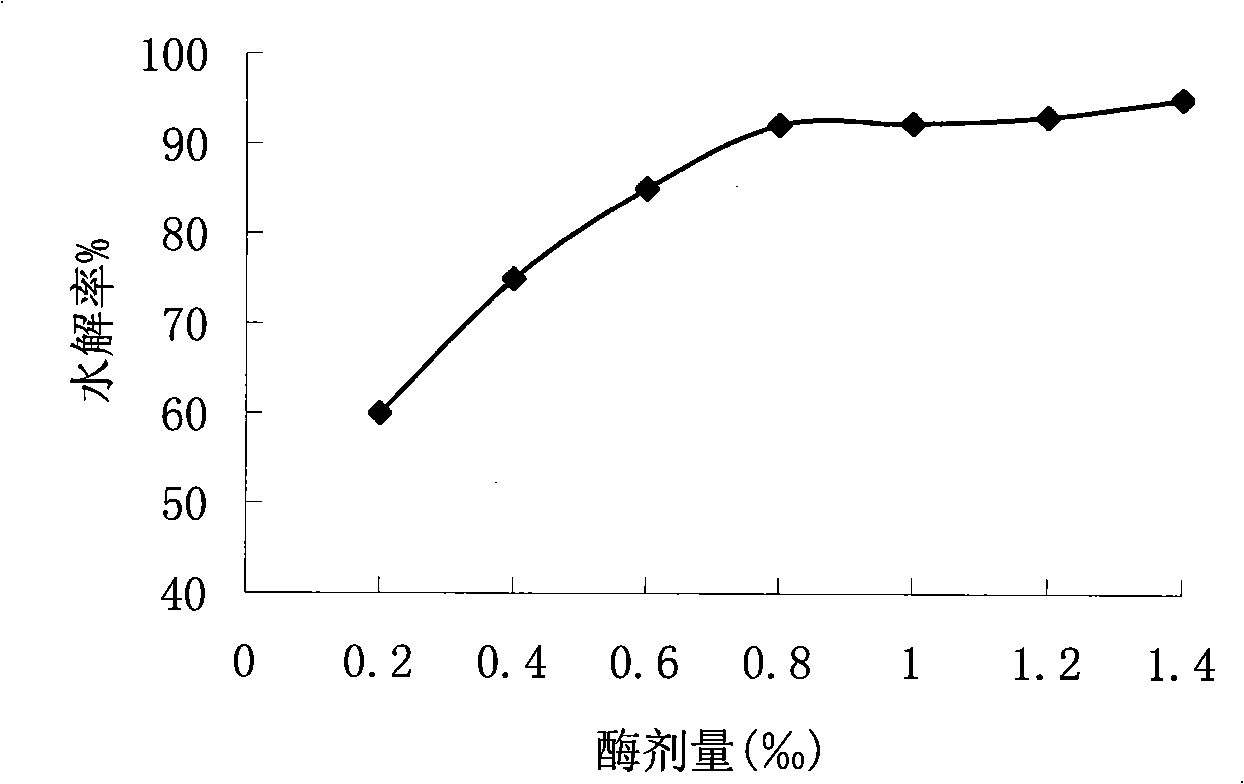

[0076] (1) The effect of the amount of enzyme added on the effect of enzymatic hydrolysis

[0077] At 50°C, take unit volume of kiwifruit puree and add pectinase with the mass fractions of 0.2‰, 0.4‰, 0.6‰, 0.8‰, 1.0‰, 1.2‰, and 1.4‰, respectively, and keep warm for 1 hour to measure the amount of pectinase in the pulp, respectively. pectin content, the test results are as follows figure 1 shown. from figure 1 It can be seen that at the stage of 0.2‰~1.0‰, with the increase of the amount of enzyme added, the hydrolysis rate of pectin increases proportionally, and at the stage of 1.0‰~1.4‰, with the increase of the amount of enzyme added, the rate of pectin hydrolysis does not increase, so the best The amount of enzyme added is 1.0‰.

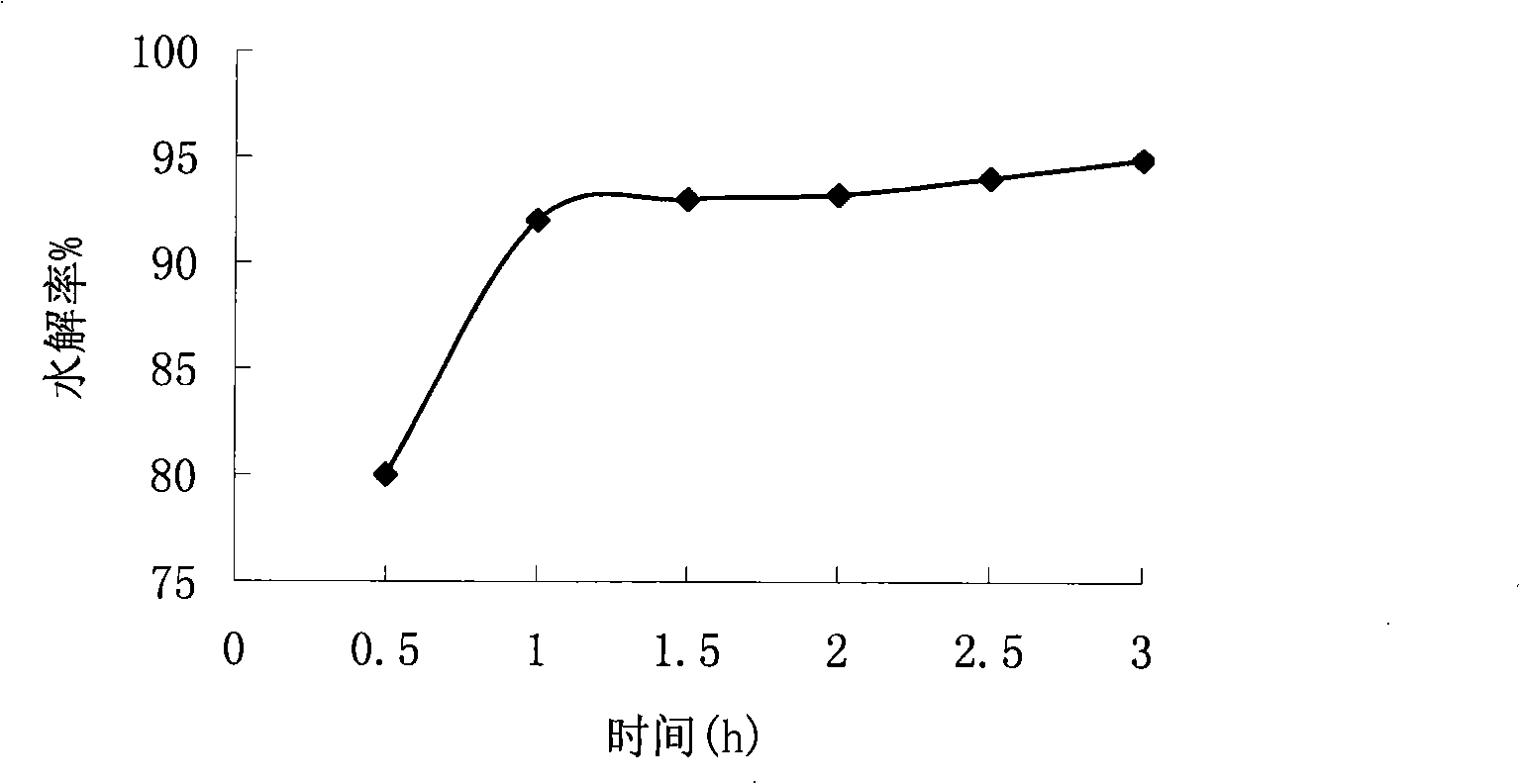

[0078] (2) Effect of enzymatic hydrolysis time on pectin hydrolysis rate

[0079] At 50°C, add 0.9mL / L or 6kg / 6T pectinase to a unit volume of kiwifruit ...

Embodiment 2

[0080] Embodiment 2: the determination of composite enzyme and clarifier joint clarification process parameters (the composite enzyme adopts Wanli composite enzyme)

[0081] (1) Determination of parameters for compound enzyme clarification of kiwi fruit juice

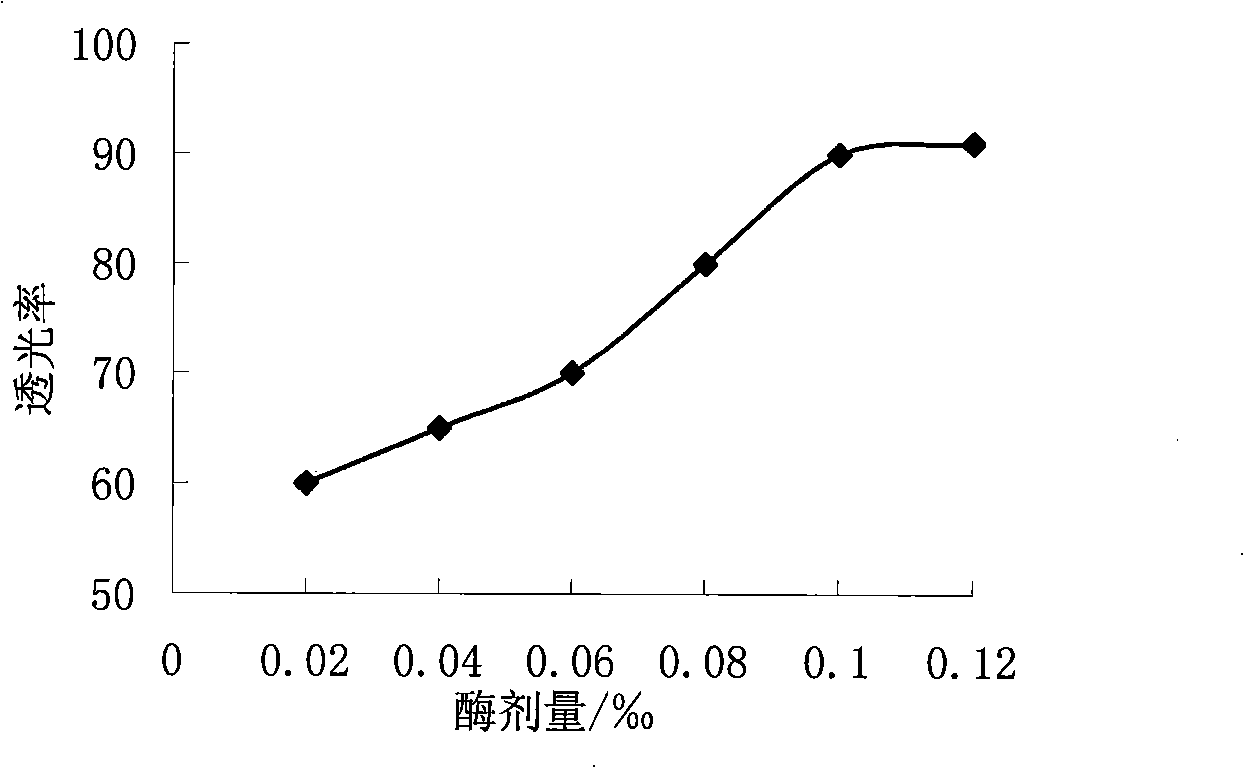

[0082] a. The effect of the amount of enzyme added on the light transmittance of kiwi fruit juice

[0083] At 50°C, take a unit volume of kiwi fruit juice, add different doses of complex enzymes to clarify enzymes, react for 30 minutes, centrifuge at 3000 rpm for 10 minutes, take the supernatant, dilute it several times, and measure its light transmittance at 625nm. The results are as follows: image 3 shown. from image 3 It can be seen that with the increase of enzyme dosage, the light transmittance of juice increases continuously, but the rate of increase decreases continuously. In the process of enzyme addition from 0.1‰ to 0.12‰, the light transmittance did not change much, so the enzyme addition of 0.1‰ was sel...

Embodiment 3

[0107] Embodiment 3: the determination of resin decolorization process parameter

[0108] (1) The kiwi fruit juice after clarification is decolorized by using granular activated carbon of the same quality and selected macroporous adsorption resin respectively, and it is found that the color of the juice after decolorization by activated carbon is blue, has fine activated carbon particles, and is difficult to obtain. The color of the fruit juice clarified by the macroporous adsorption resin is relatively normal, and the decolorization effect is good, so the macroporous adsorption resin is selected as the decolorizing agent in the production of concentrated kiwifruit clear juice.

[0109] (2) Effect of resin addition amount on decolorization effect

[0110] Use 0.5g / L, 1.0g / L, 1.5g / L, 2.0g / L, 2.5g / L, 3.0g / L to shake and decolorize the fruit juice at 30°C for 30 minutes, and then measure its color at a wavelength of 440nm. Color value, test results such as Figure 8 shown. Dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com