Formation process for lithium ion cell with high energy density

A high-energy density, lithium-ion technology, applied in the field of lithium-ion batteries, to achieve stable film formation, improve black spot interface problems, and close contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

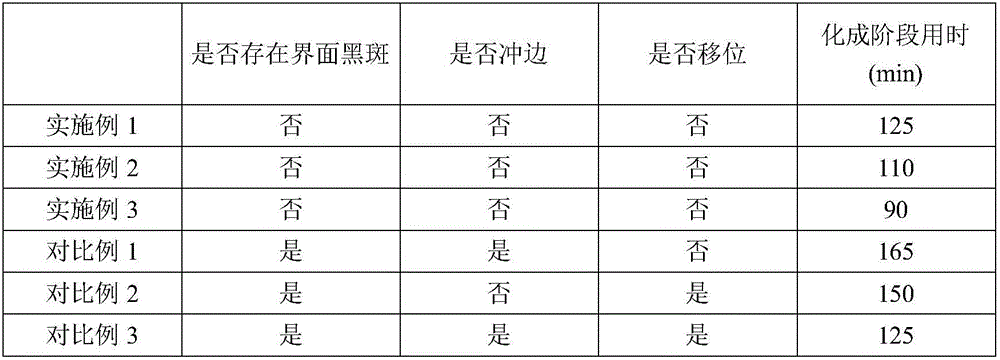

Examples

Embodiment 1

[0019] A high energy density lithium-ion cell formation process, comprising the following steps:

[0020] 1) Pre-treatment stage: At room temperature, inject electrolyte solution into the cell and let it stand for 12 hours, then place the cell at 45°C for 16 hours.

[0021] 2) Formation stage: step 1, charge the battery with a constant current of 0.05C, first apply a pressure of 300kgf to the battery, and charge for 20 minutes; then pressurize the battery to 0.2MPa, charge for 15 minutes; finally pressurize the battery To 0.3MPa, charge for 10min; the actual voltage of the cell is 2.5V; step 2, apply a pressure of 0.4MPa to the cell obtained in step 1, and charge it with a constant current of 0.2C, and the charging time is 20min; step 3, Keep the pressure of 0.4MPa, and charge the cell obtained in step 2 with a constant current of 0.8C, and the charging time is 60min. The operating temperature of the formation stage is 75°C.

[0022] 3) Baking treatment stage: Baking the cel...

Embodiment 2

[0024] A high energy density lithium-ion cell formation process, comprising the following steps:

[0025] 1) Pre-treatment stage: At room temperature, inject electrolyte solution into the cell and let it stand for 18 hours, then place the cell at 40°C for 20 hours.

[0026] 2) Formation stage: step 1, charge the cell with a constant current of 0.05C, first apply a pressure of 400kgf to the cell, charge for 18 minutes; then pressurize the cell to 0.25MPa, charge for 12 minutes; finally pressurize the cell To 0.35MPa, charge for 10min; the actual voltage of the cell is 3.0V; step 2, apply a pressure of 0.45MPa to the cell obtained in step 1, and charge it with a constant current of 0.2C, and the charging time is 20min; step 3, Keep the pressure of 0.45MPa, and charge the cell obtained in step 2 with a constant current of 0.9C, and the charging time is 50min. The operating temperature of the formation stage is 80°C.

[0027] 3) Baking treatment stage: Baking the cell obtained i...

Embodiment 3

[0029] A high energy density lithium-ion cell formation process, comprising the following steps:

[0030] 1) Pre-treatment stage: At room temperature, inject electrolyte solution into the cell, let it stand for 24 hours, then place the cell at 40°C, and let it stand for 24 hours.

[0031] 2) Formation stage: step 1, charge the battery with a constant current of 0.05C, first apply a pressure of 500kgf to the battery, and charge for 15 minutes; then pressurize the battery to 0.3MPa, charge for 10 minutes; finally pressurize the battery To 0.4MPa, charge for 5min; the actual voltage of the cell is 3.0V; step 2, apply a pressure of 0.5MPa to the cell obtained in step 1, and charge it with a constant current of 0.2C, and the charging time is 20min; step 3, Maintain a pressure of 0.5MPa, and charge the cell obtained in step 2 with a constant current of 1.0C for 40 minutes. The operating temperature of the formation stage is 85°C.

[0032] 3) Baking treatment stage: Baking the cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com