High molecular nano composite film and preparing method thereof

A nano-composite and polymer technology, applied in the field of polymer nano-composite film and its preparation, can solve the problems of small particle size and large surface atomic ratio, easy agglomeration, unstable energy, etc., and achieves stable film-making performance, The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

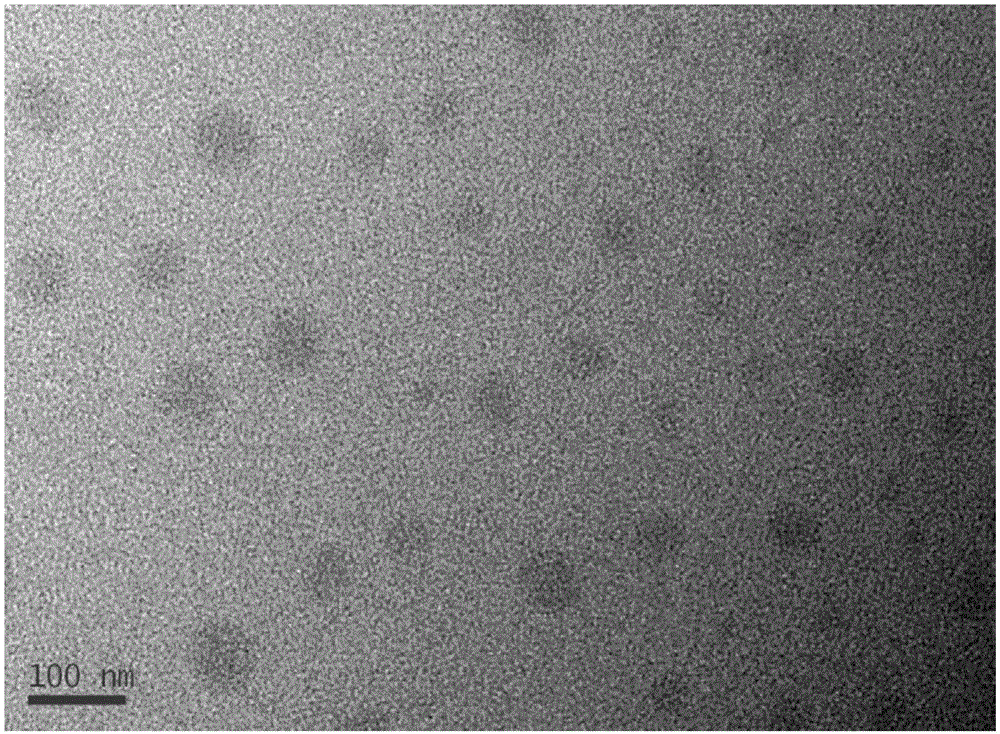

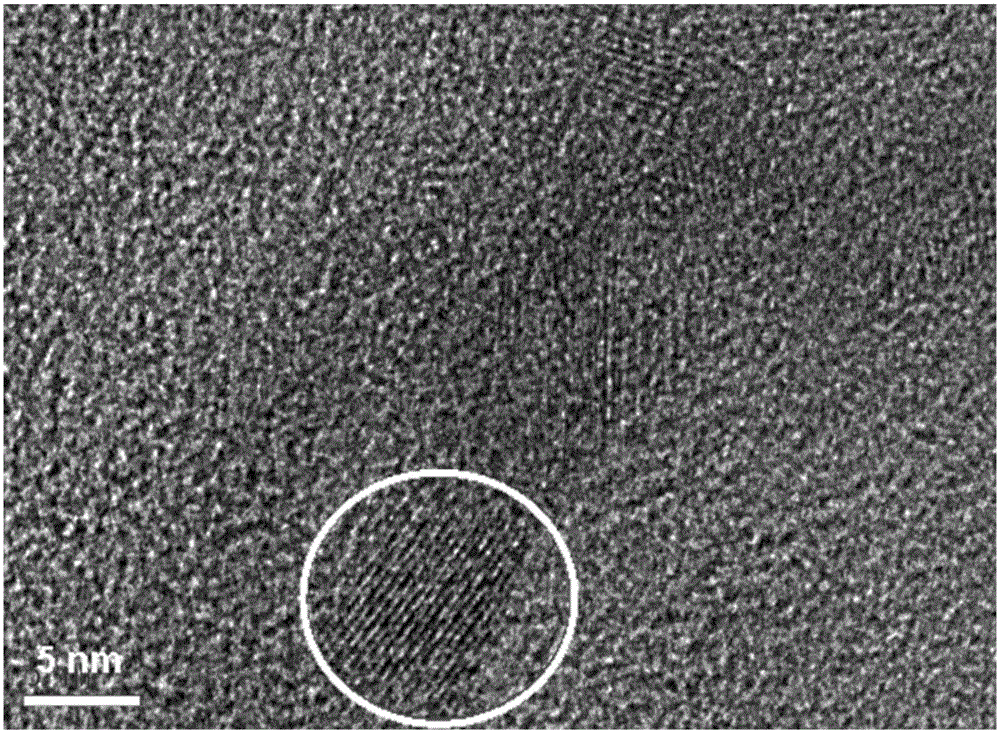

[0043]A kind of macromolecule nanocomposite film of the present invention, comprises polymethyl methacrylate matrix (being PMMA matrix) and the nanometer Cu and [emim] BF dispersed in PMMA matrix 4 (The molecular formula is shown in formula I), that is, the polymer nanocomposite film is specifically Cu / [emim]BF 4 / PMMA film.

[0044]

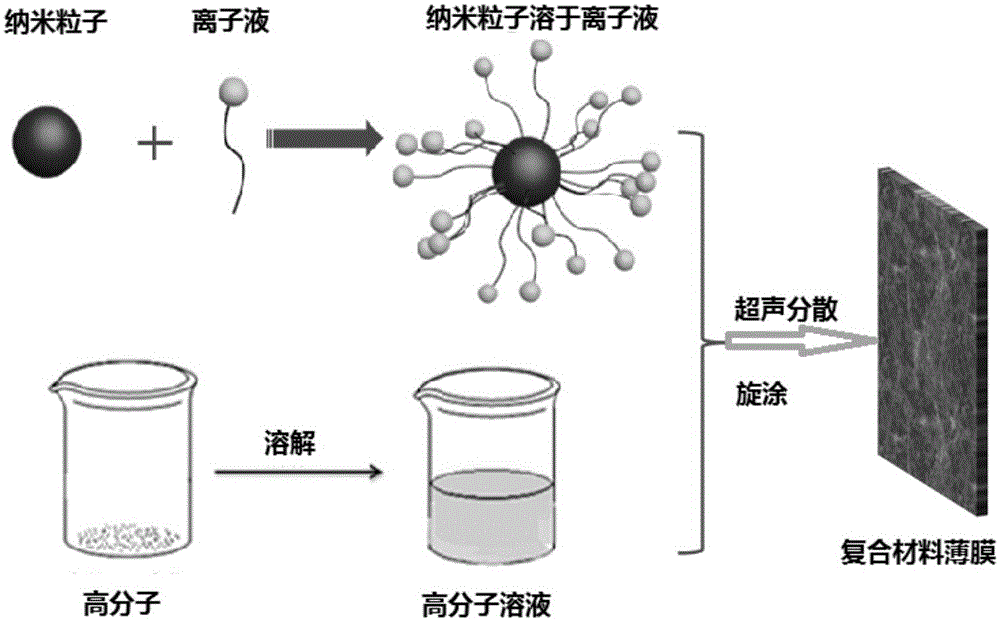

[0045] A kind of preparation method of the above-mentioned polymer nanocomposite film of the present embodiment, flow process see figure 1 , including the following steps:

[0046] (1) Weigh 1mg of nano-copper powder with an electronic balance. The average particle size of the nano-copper powder is 10nm~30nm, and add it to 10mL[emim]BF 4 In the ionic liquid, under the conditions of air isolation and argon protection, ultrasonically disperse for 2 hours to make it evenly mixed to obtain the first dispersion liquid, namely [emim]BF 4 -Cu sol.

[0047] (2) Weigh 0.06975g of PMMA with an electronic balance and add it into 1ml of dichlorometha...

Embodiment 2

[0057] A polymer nanocomposite film of the present invention, comprising polystyrene matrix (i.e. PS matrix) and nano Cu and [emim] BF dispersed in PS matrix 4 (The molecular formula is shown in formula I), that is, the polymer nanocomposite film is specifically Cu / [emim]BF 4 / PS film.

[0058]

[0059] A preparation method of the polymer nanocomposite film of the above-mentioned present embodiment, comprising the following steps:

[0060] (1) Weigh 1mg of nano-copper powder with an electronic balance. The average particle size of the nano-copper powder is 10nm~30nm, and add it to 10mL[emim]BF 4 In the ionic liquid, under the conditions of air isolation and argon protection, ultrasonically disperse for 2 hours to make it evenly mixed to obtain the first dispersion liquid, namely [emim]BF 4 -Cu sol.

[0061] (2) 0.06975 g of PS was weighed with an electronic balance and added to 1 mL of dichloromethane solvent, ultrasonically dispersed for 2 hours, and mixed uniformly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com